Magnetorheological torsional vibration damper for engine

A torsional vibration damper and magneto-rheological technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of reducing the resonance amplitude of the crankshaft, failing to achieve the vibration reduction effect, and non-adjustable damping characteristics of the shock absorber. , to achieve good vibration damping effect, good vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. It should be noted that this embodiment is illustrative rather than limiting.

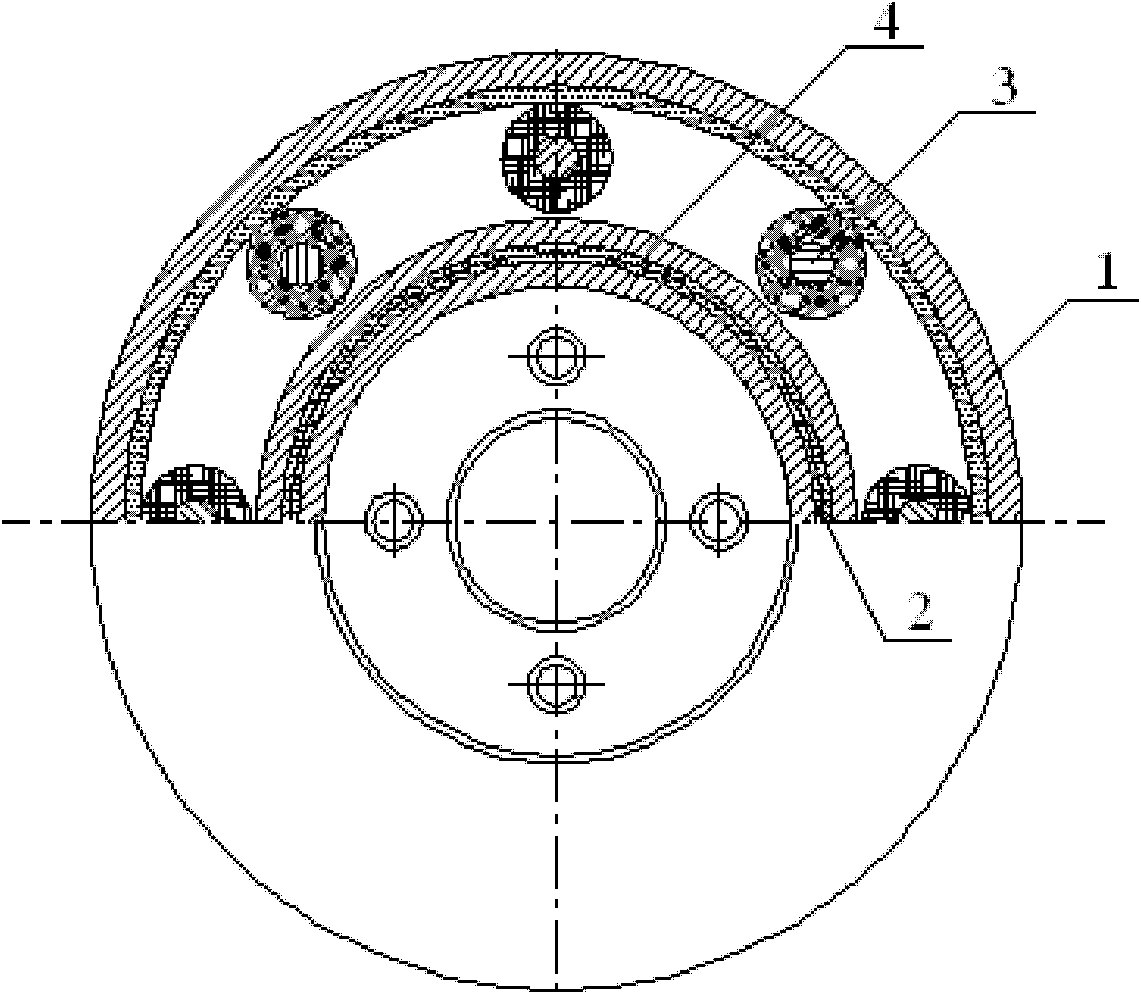

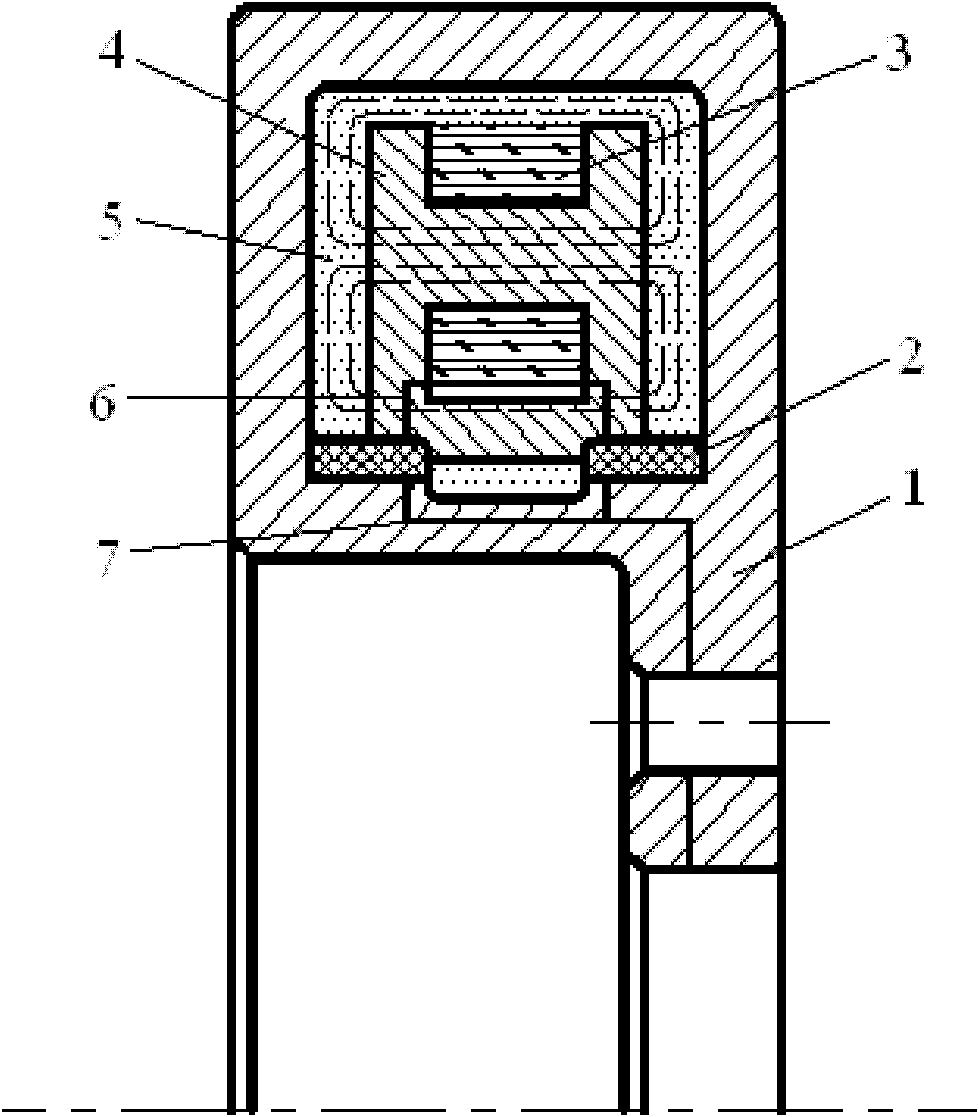

[0014] The structure of the engine magneto-rheological torsional vibration damper is as follows: an inertial disc 4 is provided in the annular shell 1, and an anti-friction bushing 2 is provided on the inner and outer ends of the annular shell 1, and the inertial disc 4 is placed in the annular shell. The body can freely rotate around the wear-resistant bushing 2 . The inertial disc is equipped with a conductive coil 3, and the gap between the ring shell and the inertial disc is filled with magnetorheological fluid 5. The anti-friction bushing is connected with a wire 6, and the wire is led out from the central axis of the shock absorber through the insulating conduit 7 of the annular shell. The parts where the wear-reducing bushing 2 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com