Parameter self-adapting and regulation leather bag type hydraulic accumulator

A technology of self-adaptive adjustment and hydraulic accumulator, applied in mechanical equipment and other directions, to achieve the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

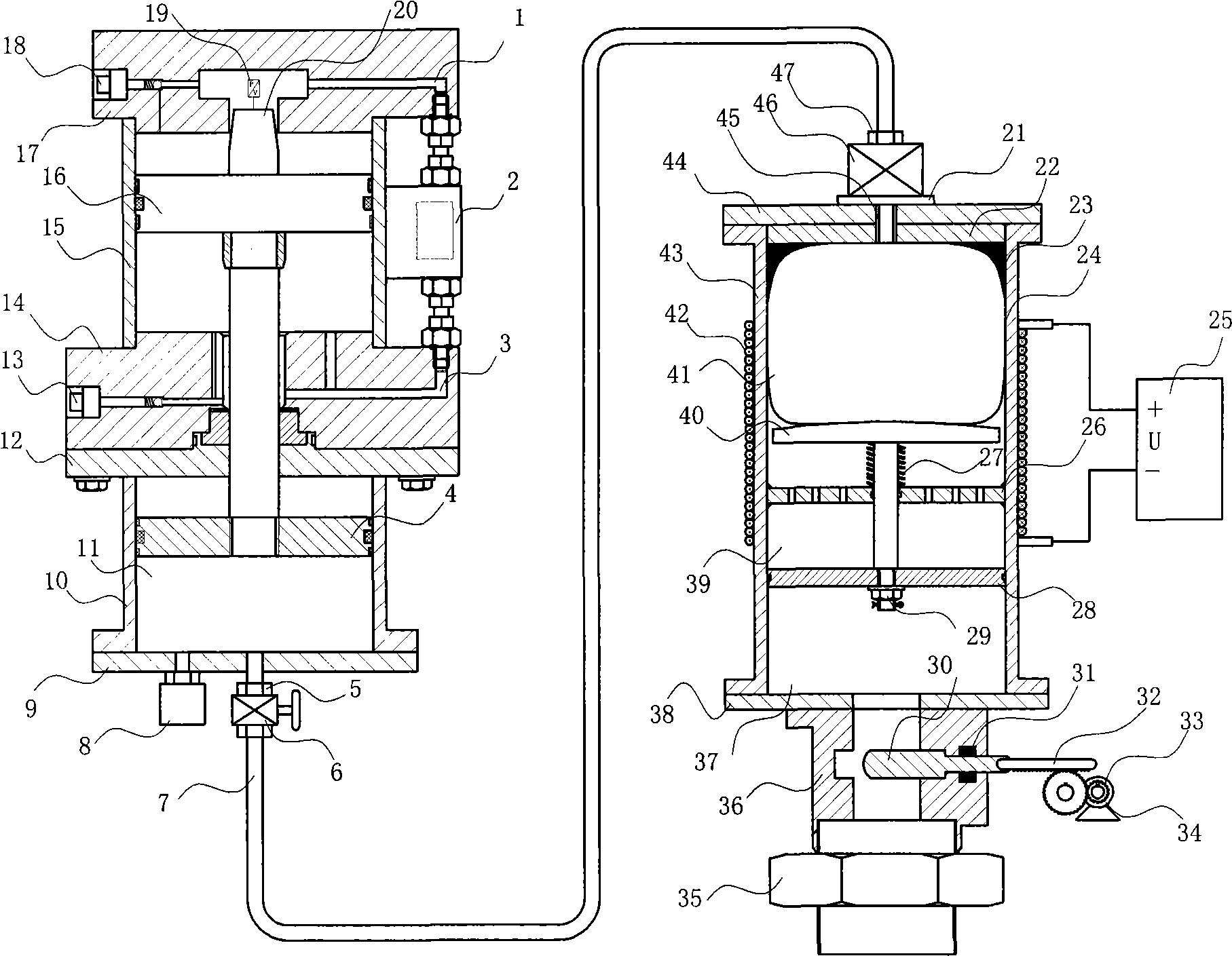

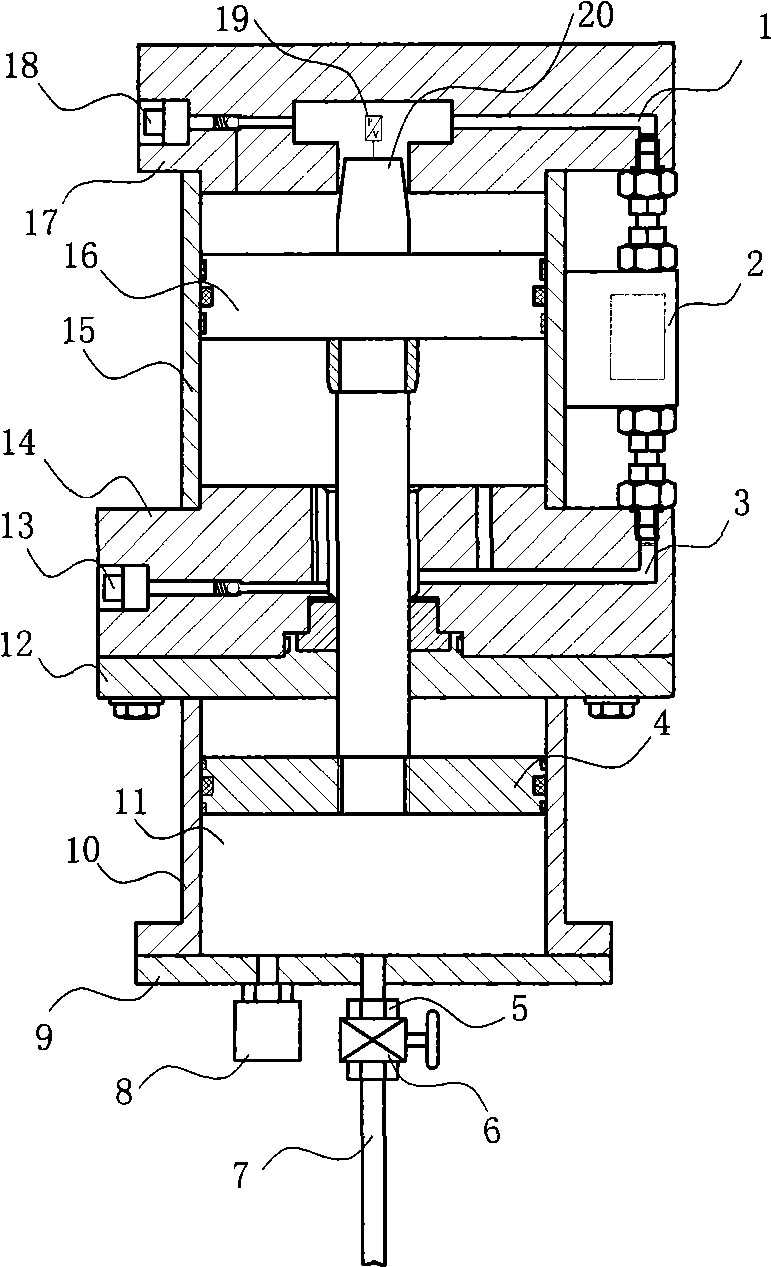

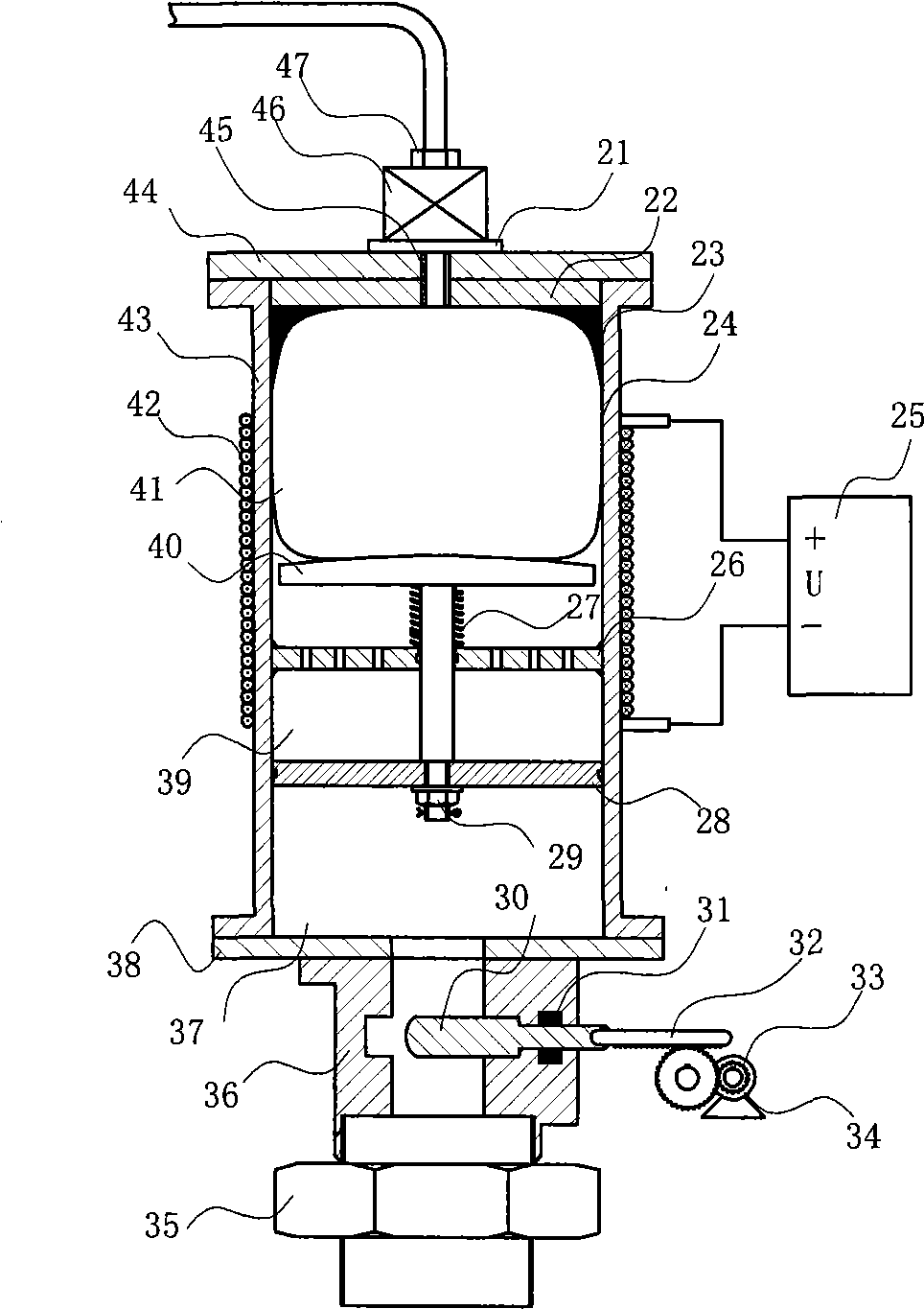

[0017] figure 1 The utility model discloses a bladder type hydraulic accumulator for self-adaptive adjustment of parameters. The second air chamber 41 of the variable parameter accumulator device communicates with the first air chamber 11 of the on-line adjustment accumulator device through the high-pressure solenoid valve 46 and the high-pressure gas pipeline 7 (see figure 2 , image 3 ), the oil inlet valve sleeve 36 of the parameter variable accumulator device is connected with the hydraulic system with the oil inlet valve sleeve (35).

[0018] In the online adjustment accumulator device, the hydraulic cylinder 15 is equipped with a displacement sensor 19 and a distributor 2, the hydraulic cylinder extends the oil circuit 1 and the hydraulic cylinder retracts the oil circuit 3 to connect with the distributor 2, and the hydraulic cylinder extends the oil circuit 1 When the oil enters, the hydraulic cylinder retracts and the oil circuit 3 returns oil, the piston 16 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com