Preparation method of ionic liquid modified graphite micro plate/silicon rubber conductive composite material

A conductive composite material and ionic liquid technology, applied in the field of silicone rubber, can solve problems such as defective conductive network, difficulty in uniform dispersion of carbon filler, and easy agglomeration of carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

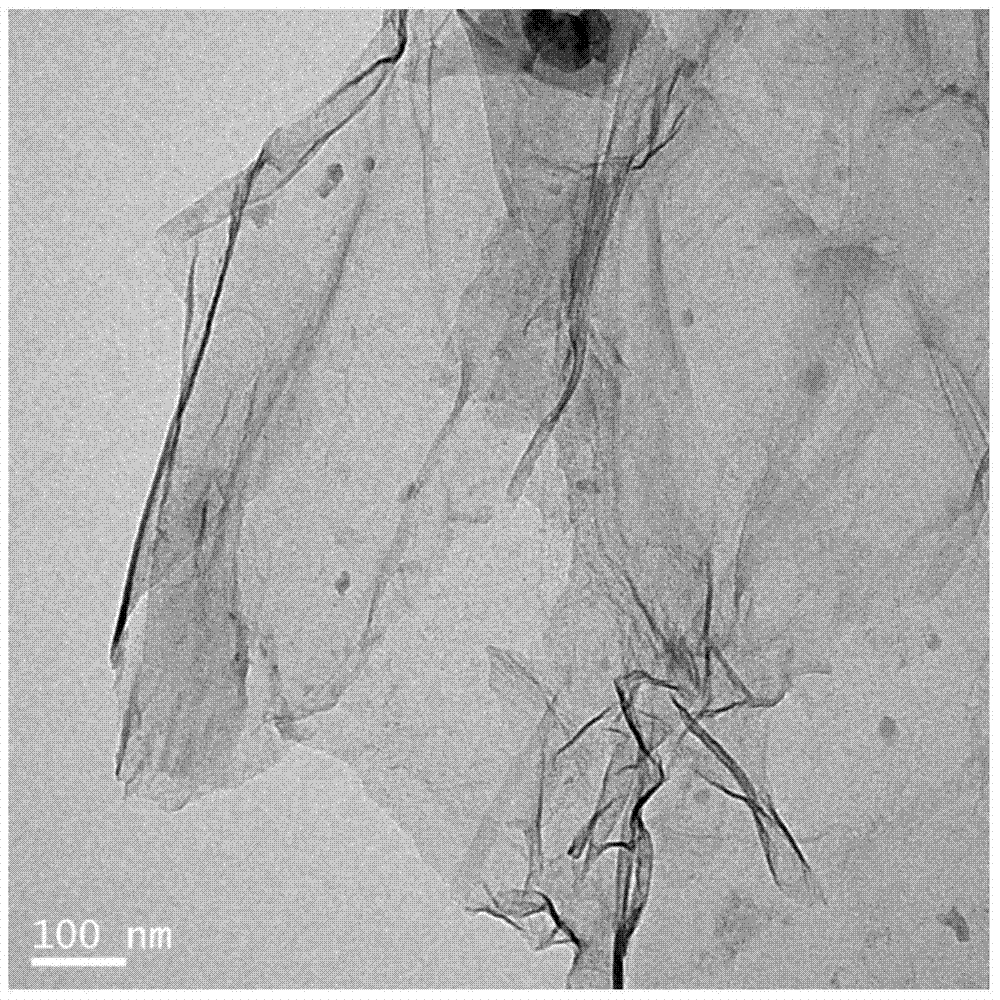

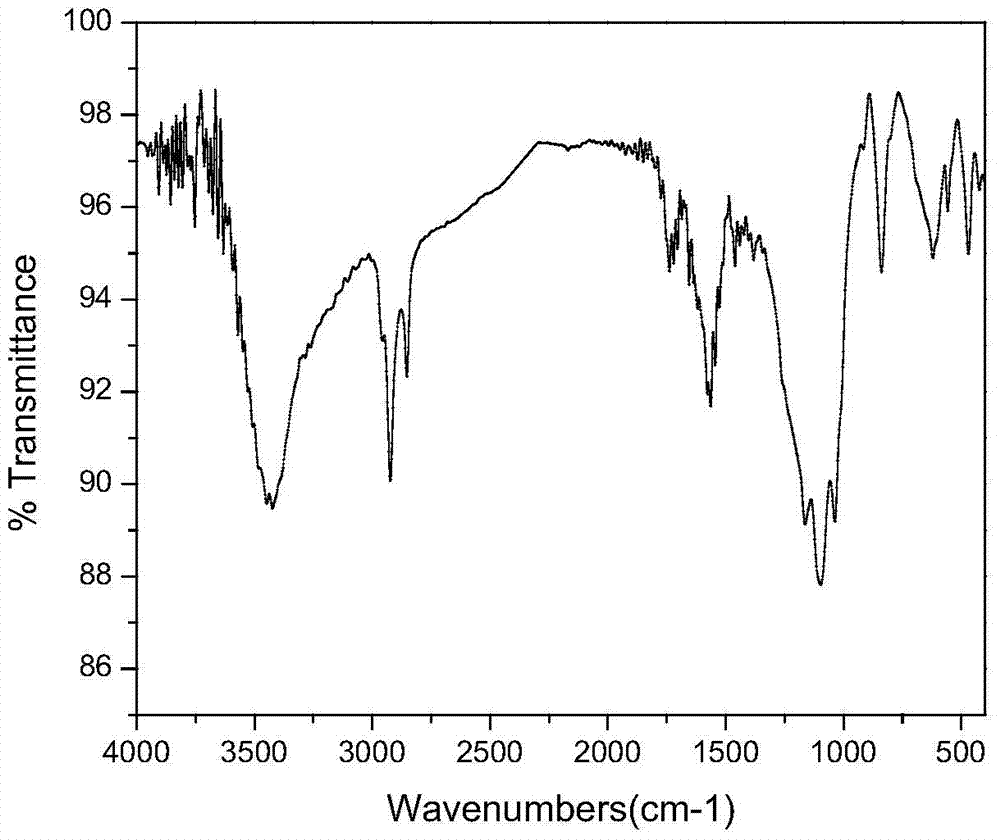

[0023] Graphite oxide was heated at 600°C for 120s to obtain worm-like expanded graphite. Add expanded graphite and ionic liquid into pure ethanol solvent at a mass ratio of 1:1, and after preparing a 0.023 g / ml solution, ultrasonically disperse for 1 h. After the mixed solution was ball milled for 0.5 h by mechanical ball milling method, the ionic liquid modified graphite microflakes were obtained by drying. figure 1 It is the transmission electron micrograph of embodiment one product, figure 2 It is the infrared test spectrogram of embodiment one product. Depend on figure 1 It can be seen that expanded graphite was successfully mechanically exfoliated into single-layer graphite microflakes under the modification of ionic liquid, and the flakes were wrinkled. figure 2 Show embodiment one product at 3430cm -1 There is obvious hydroxyl stretching vibration on the peak, at 2650cm -1 and 2920cm -1 The peak has H2O or -OH vibration in the carboxyl group, at 1103cm -1 The ...

Embodiment 2

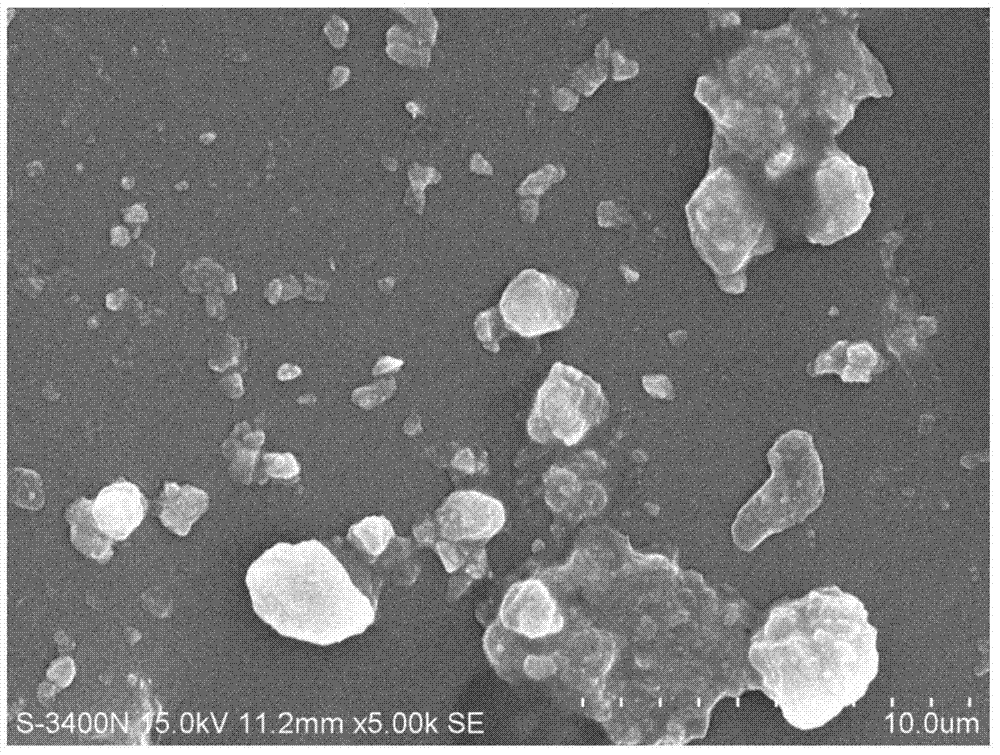

[0025] Add 0.1 g of the ionic liquid-modified graphite microflake product of Example 1 and 10 g of liquid silicone rubber raw rubber into n-hexane solvent to form a 0.1 g / ml solution. After ultrasonic dispersion for 0.5 h, the mixed solution was stirred in a water bath at 80° C. for 2 h, and the n-hexane solvent was evaporated to obtain a viscous mixture. Add curing agent to the viscous mixture (the liquid silicone rubber raw rubber and curing agent are mixed at a mass ratio of 10:1), and the ultrasonic dispersion is uniform. The ionic liquid modified graphite microflake / silicone rubber composite was obtained by heating and curing in vacuum at 150° C. for 2 h. image 3 It is a section scanning electron micrograph of the ionic liquid modified graphite microchip / silicone rubber composite material of embodiment 2. Depend on image 3 It can be seen that the ionic liquid modified graphite microflakes can be evenly distributed in the matrix of the silicone rubber composite materia...

Embodiment 3

[0027] Add 0.3 g of the ionic liquid modified graphite microsheet product of Example 1 and 10 g of liquid silicone rubber raw rubber into n-hexane solvent to form a 0.1 g / ml solution. After ultrasonic dispersion for 0.5 h, the mixed solution was stirred in a water bath at 80° C. for 2 h, and the n-hexane solvent was evaporated to obtain a viscous mixture. Add curing agent to the viscous mixture (the liquid silicone rubber raw rubber and curing agent are mixed at a mass ratio of 10:1), and the ultrasonic dispersion is uniform. The ionic liquid modified graphite microflake / silicone rubber composite was obtained by heating and curing in vacuum at 150° C. for 2 h. Figure 4 It is a section scanning electron micrograph of the ionic liquid modified expanded graphite / silicone rubber composite material of embodiment 3. Depend on Figure 4 It can be seen that the ionic liquid-modified graphite microflakes can be evenly distributed in the matrix of the silicone rubber composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com