Sample handling system

A sample processing system and sample technology, applied in the field of sample processing systems, can solve problems such as injection moldable materials and unreliable molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

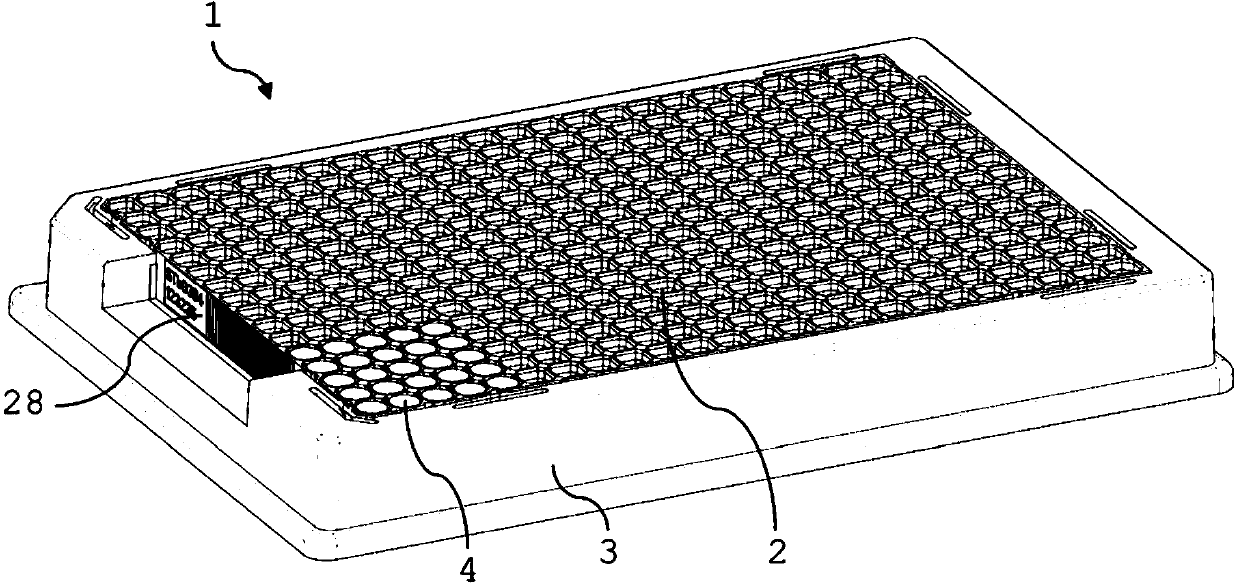

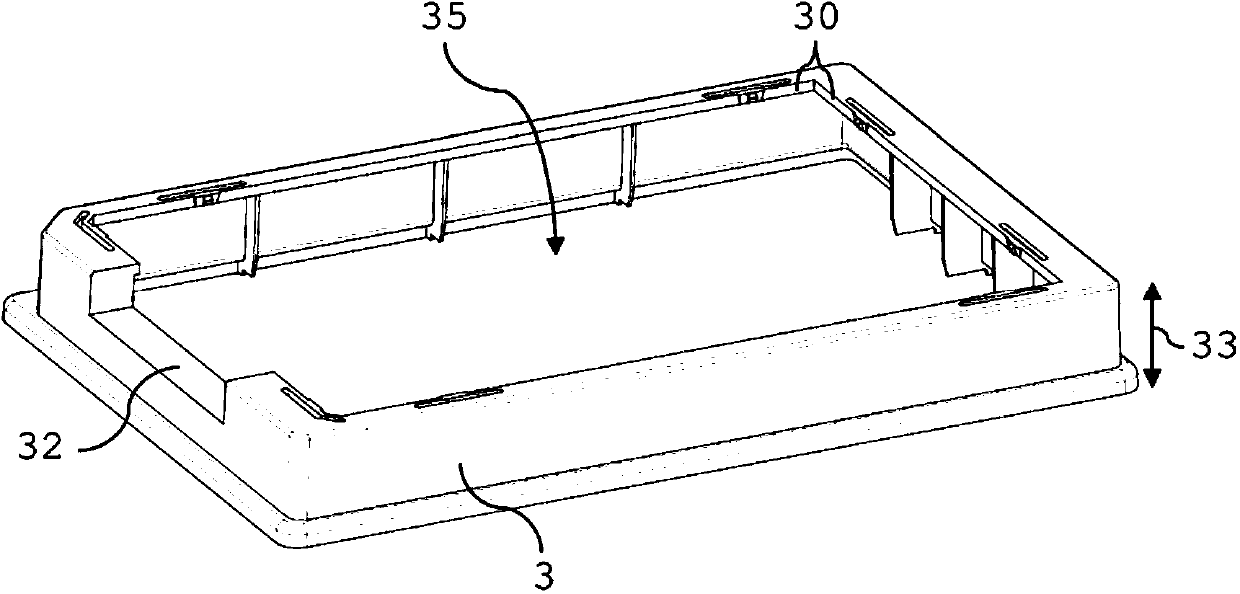

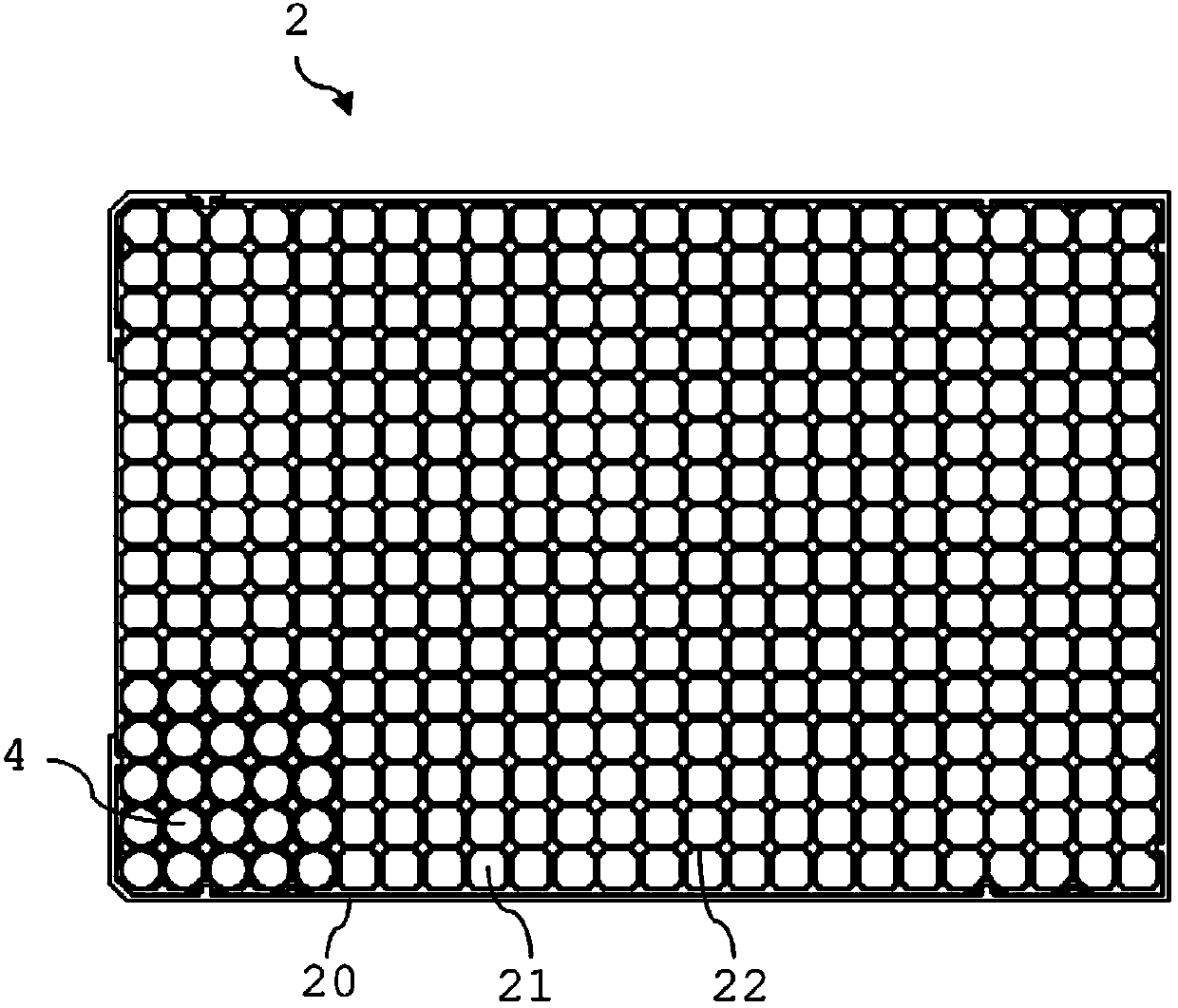

[0045] figure 1 A microplate 1 of a sample processing system according to one embodiment of the invention is shown. The microplate 1 comprises a frame 3 and individual mesh inserts 2 that have been attached to the frame 3 . figure 2 shows frame 3 alone, and image 3 show figure 1 The individual grids 2 of the microplate 1, and for the sake of clarity, these figures are described together below. The frame 3 defines the entire lateral profile of the microplate 1 . The outer contour of the frame 3 is rectangular and has the size of a standard microplate 1 . This standard outer profile allows the microplate 1 to be handled using standard equipment designed to handle standard microplates. The insertion height 33 of the frame 3 is generally not limited to specific dimensions but is related to the number of grid inserts 2 accommodated in the frame 3 . In this embodiment, the insertion height 33 of the frame 3 is slightly greater than or equal to the overall height of a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com