Manufacturing automation system components compatibility and performance testing with integrated virtual and real environment

a technology of manufacturing automation and components, applied in the field of system and method for emulating a manufacturing automation system, can solve the problems of inability to perform field testing, inability to test in the field, and excessive cost of creating and maintaining duplicates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

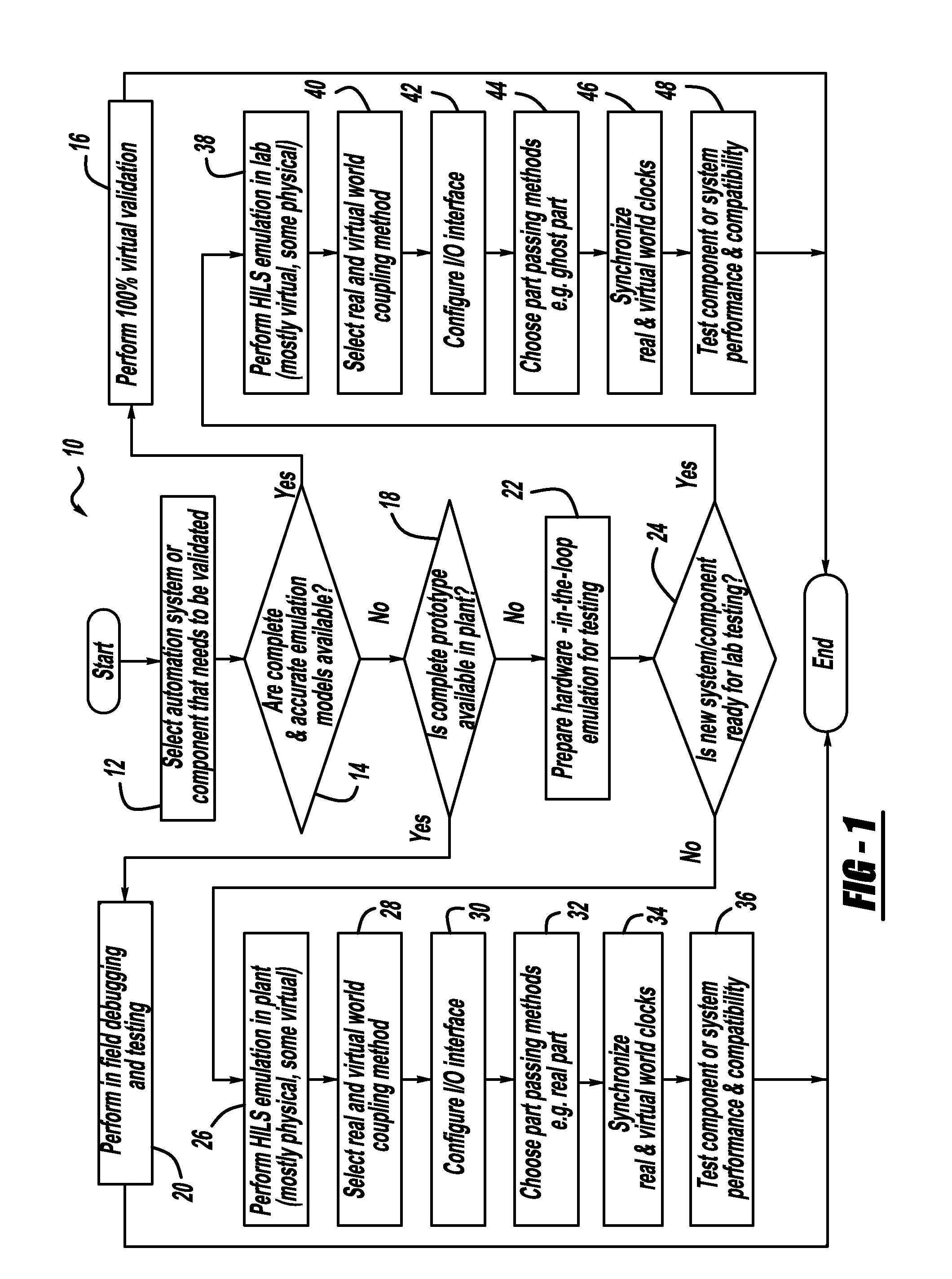

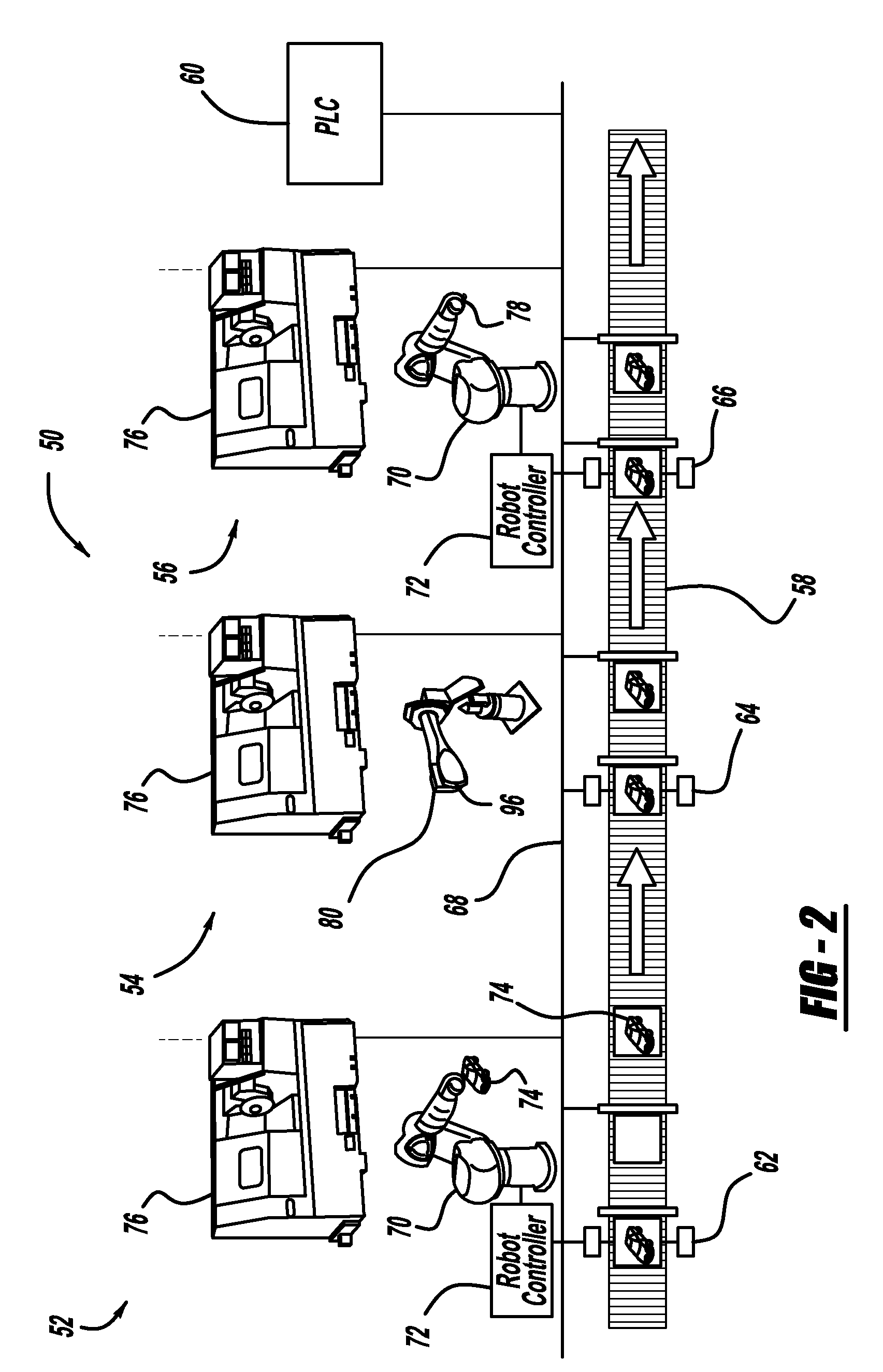

[0031]The following discussion of the embodiments of the invention directed to a system and method for providing hardware-in-the-loop emulation in a manufacturing process to provide component compatibility testing and system performance prediction is merely exemplary in nature and is in no way intended to limit the invention or its application or uses. For example, the present invention has particular application for manufacturing processes in an automotive manufacturing plant. However, as will be appreciated by those skilled in the art, the system and method of the invention may have application for other production facilities.

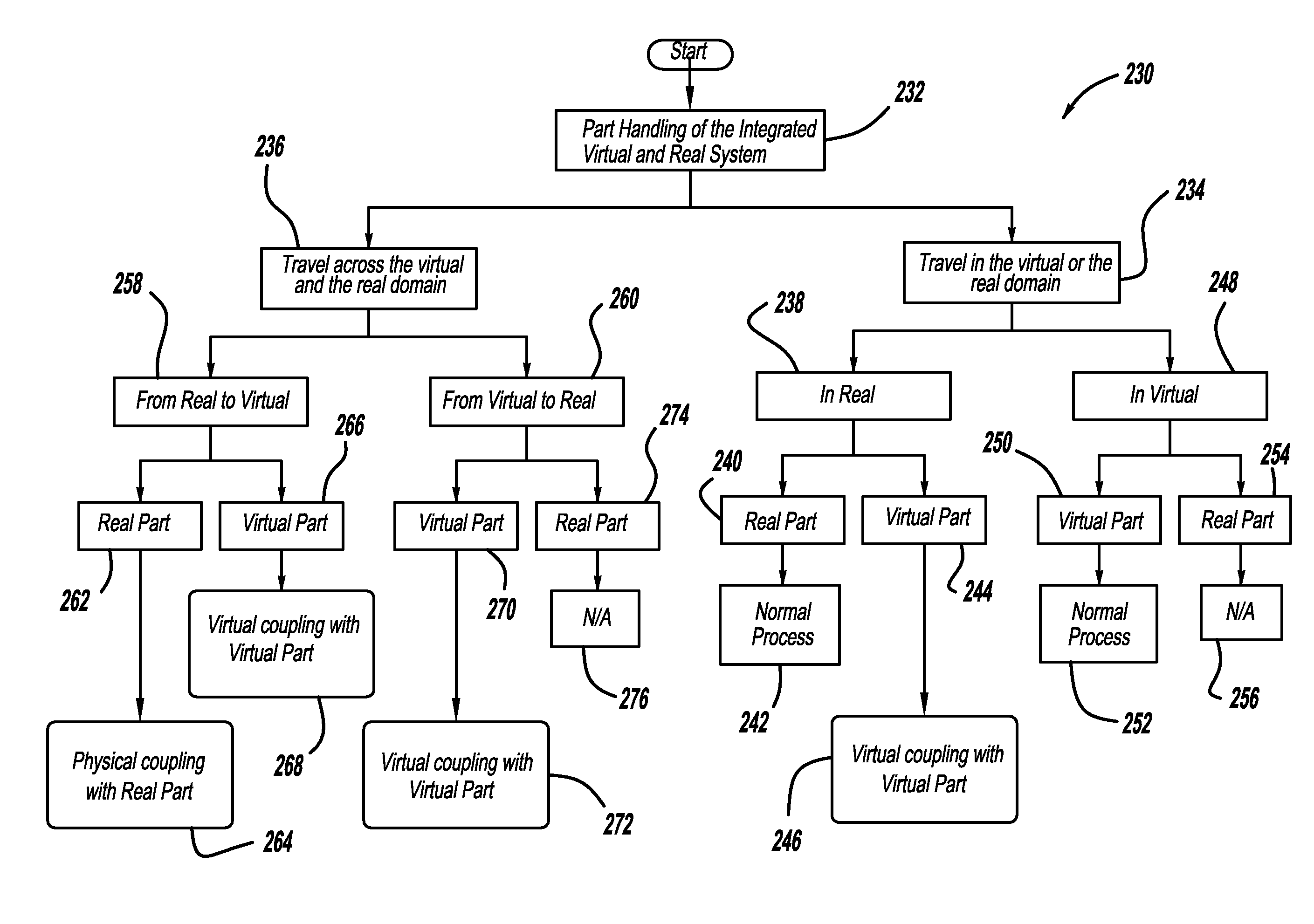

[0032]As will be discussed in detail below, the present invention integrates physical and emulated automation components with data and information exchange between the virtual world and the real world. The invention provides an effective platform for developing and testing hardware components that are difficult or time consuming to simulate with existing reso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com