Methods and apparatus for cycle time improvements for atomic layer deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

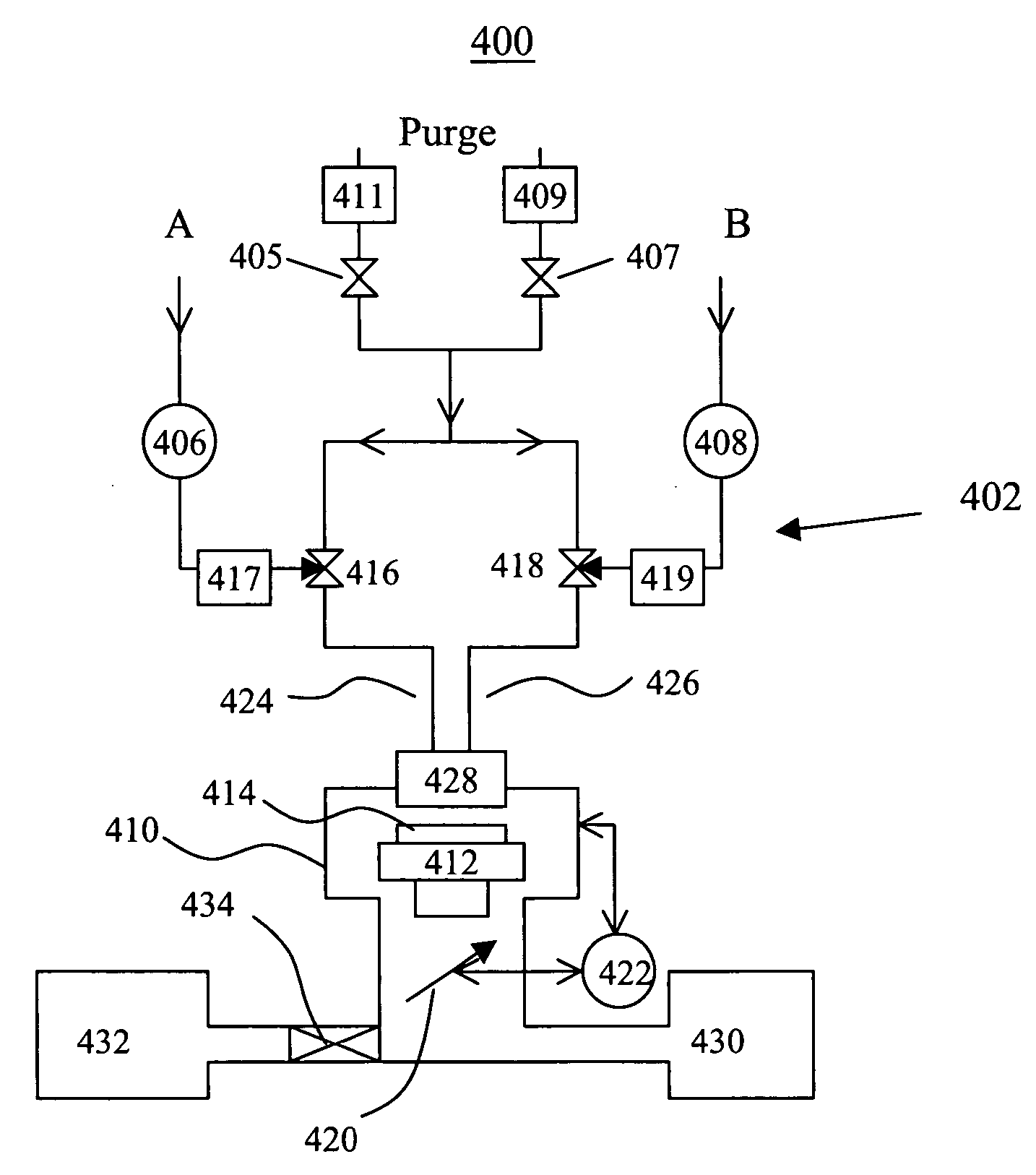

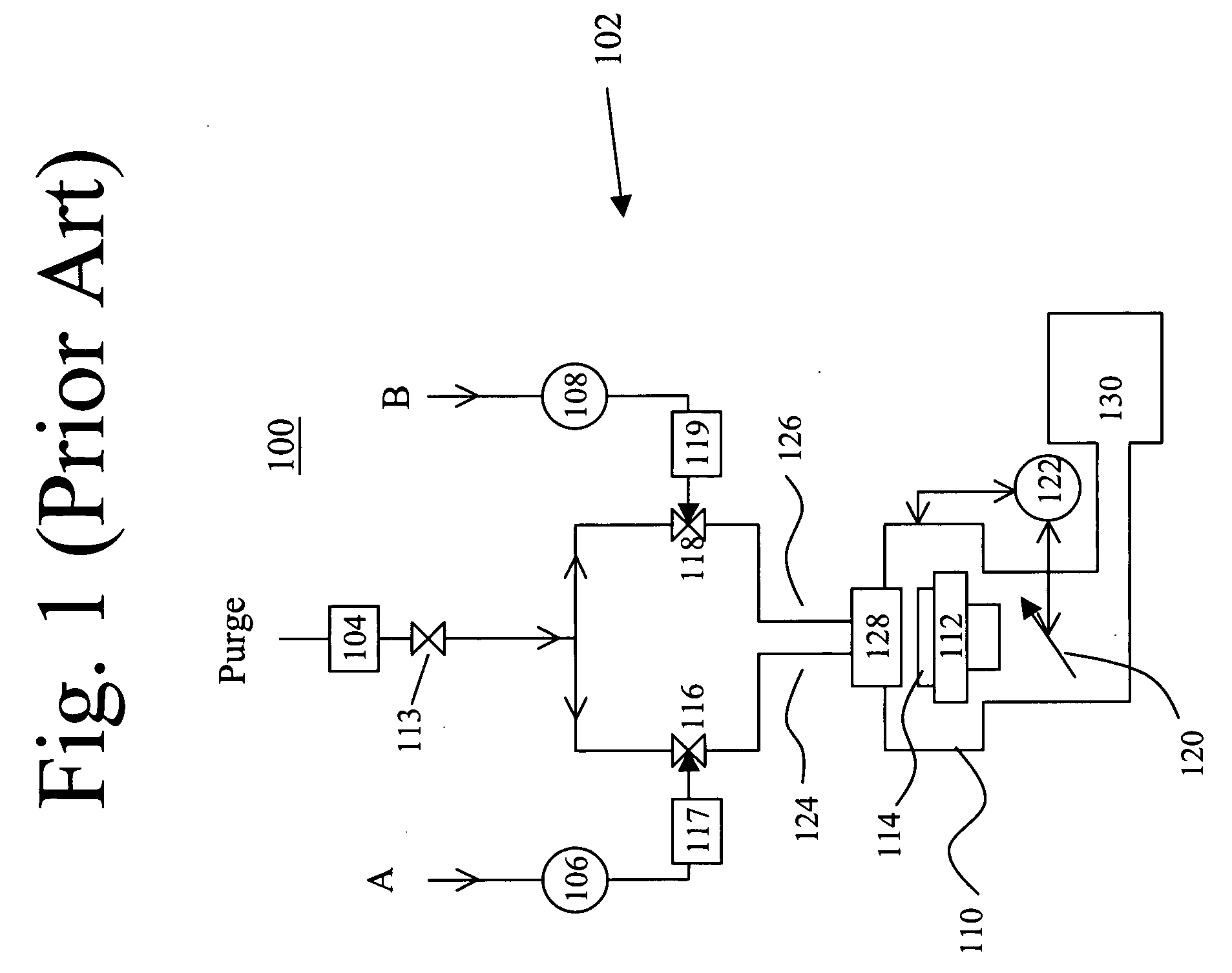

Described herein are methods and systems for cycle time improvements in ALD processes. In various embodiments, the present invention provides multi-level flow sources using pressure controlled and / or passive conductance components combined with a dual (or, more generally multiple) pump (or dual or multiple pump capacity) arrangement. Unlike the multi-level flow systems described above, in the present invention a high purge flow does not have to flow during the exposure pulse, resulting in more economical operation with respect to consumables usage. Both lower cost and better dynamic time-dependent performance is obtained, in some embodiments, by the use of pressure controlled components instead of mass flow controllers. Further, in some embodiments the use of an independent, direct-coupled conduit for neutral gas flow, instead of a purge bypass, provides multi-level purge source capability without the need for continual operation of a high purge flow.

In addition to reduced consum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Electrical conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com