Miniature camera device with directly adhered optical filter and manufacturing method thereof

A production method and filter technology, applied in the field of camera, mobile phone or tablet computer, can solve the problems of incompatibility with lightness, thinness, small size, enhanced product reliability, and large size of camera module, so as to reduce the occupied space and enhance the Reliability, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to be able to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail, the purpose of which is only to better understand the content of the present invention and not to limit the protection scope of the present invention.

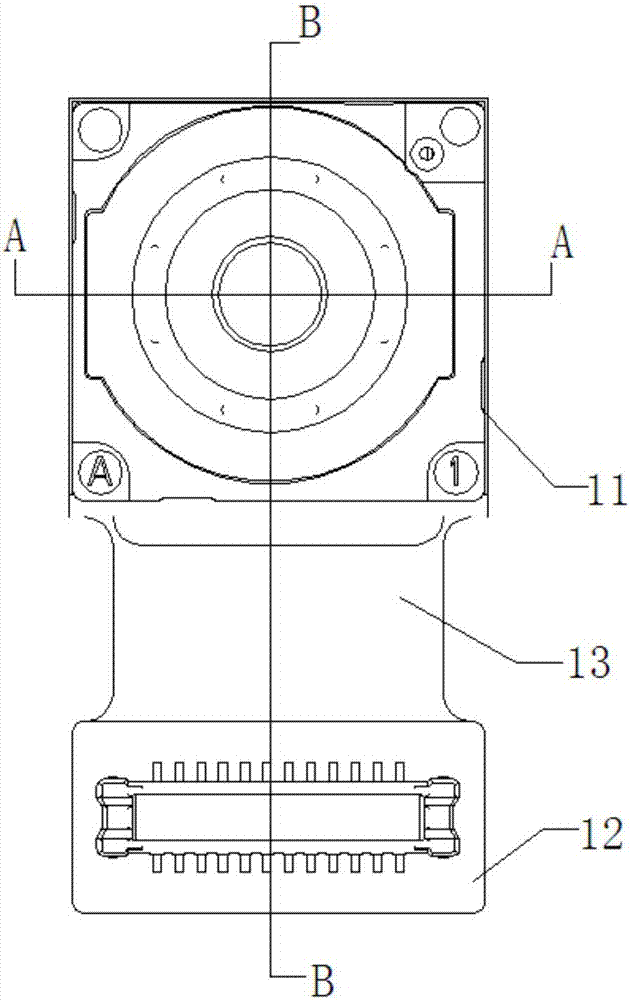

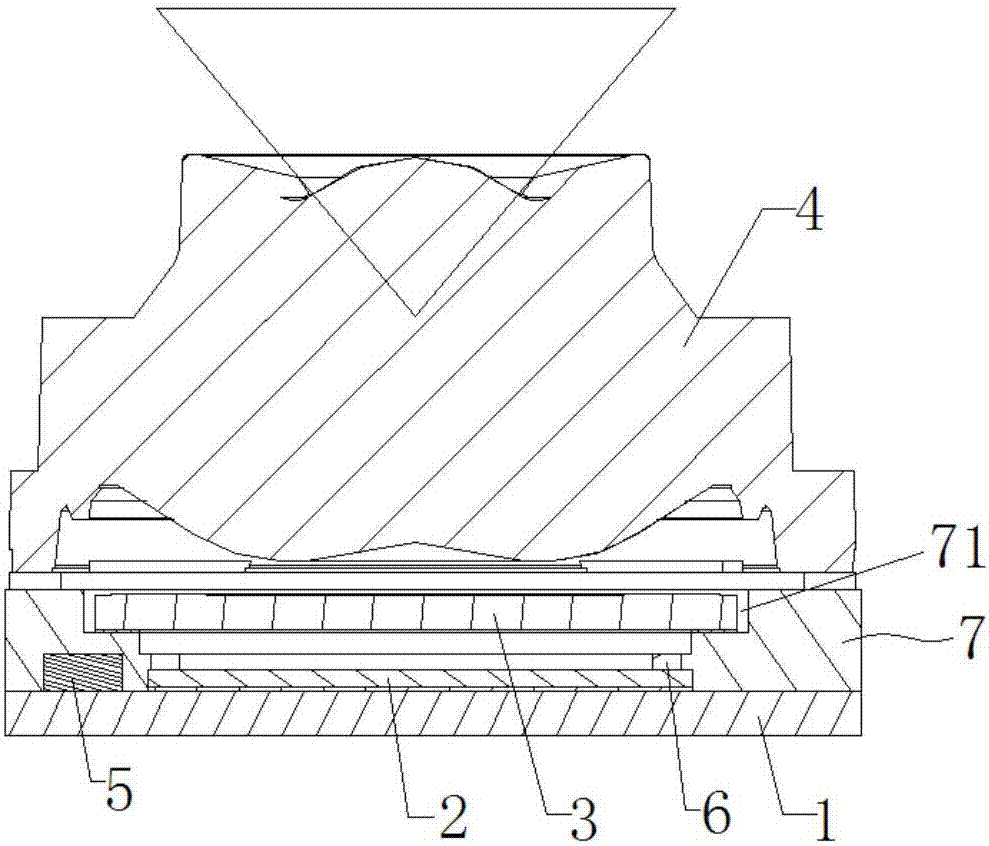

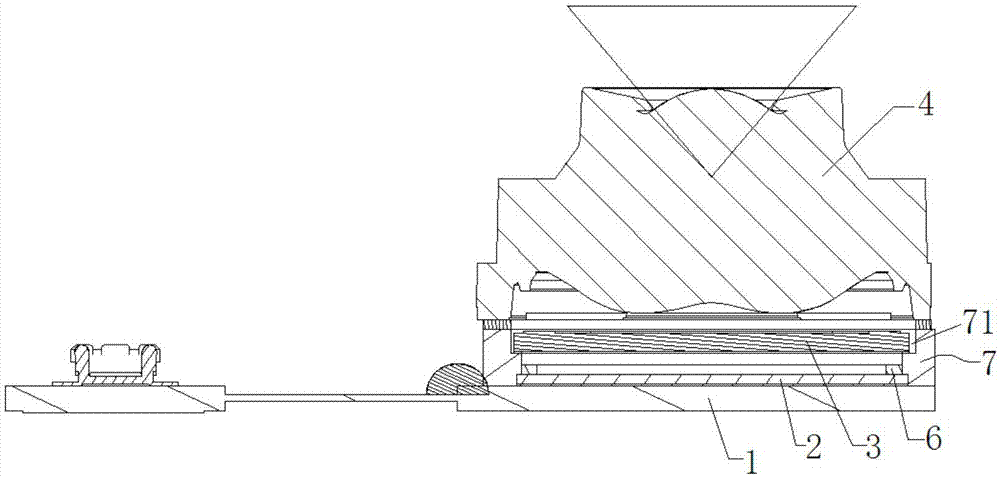

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a miniaturized camera device with directly attached filters includes a circuit board 1, a photosensitive chip 2, a filter 3, and a lens assembly 4. The photosensitive chip is mounted on the middle of the circuit board, and the The circuit board around the photosensitive chip has a passive component 5 and a gold wire connecting the photosensitive chip and the passive component. That is, the photosensitive chip on the circuit board has passive components and metal circuits on the peripheral side, and the photosensitive chip and the metal circuit on the circuit board are gold-plated Wires are electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com