Horizontal glass straight-line four-side grinding wheel type edge grinding machine

An edger, straight line technology, applied in the field of machinery, to avoid crushing and scratches, improve work efficiency, and improve the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

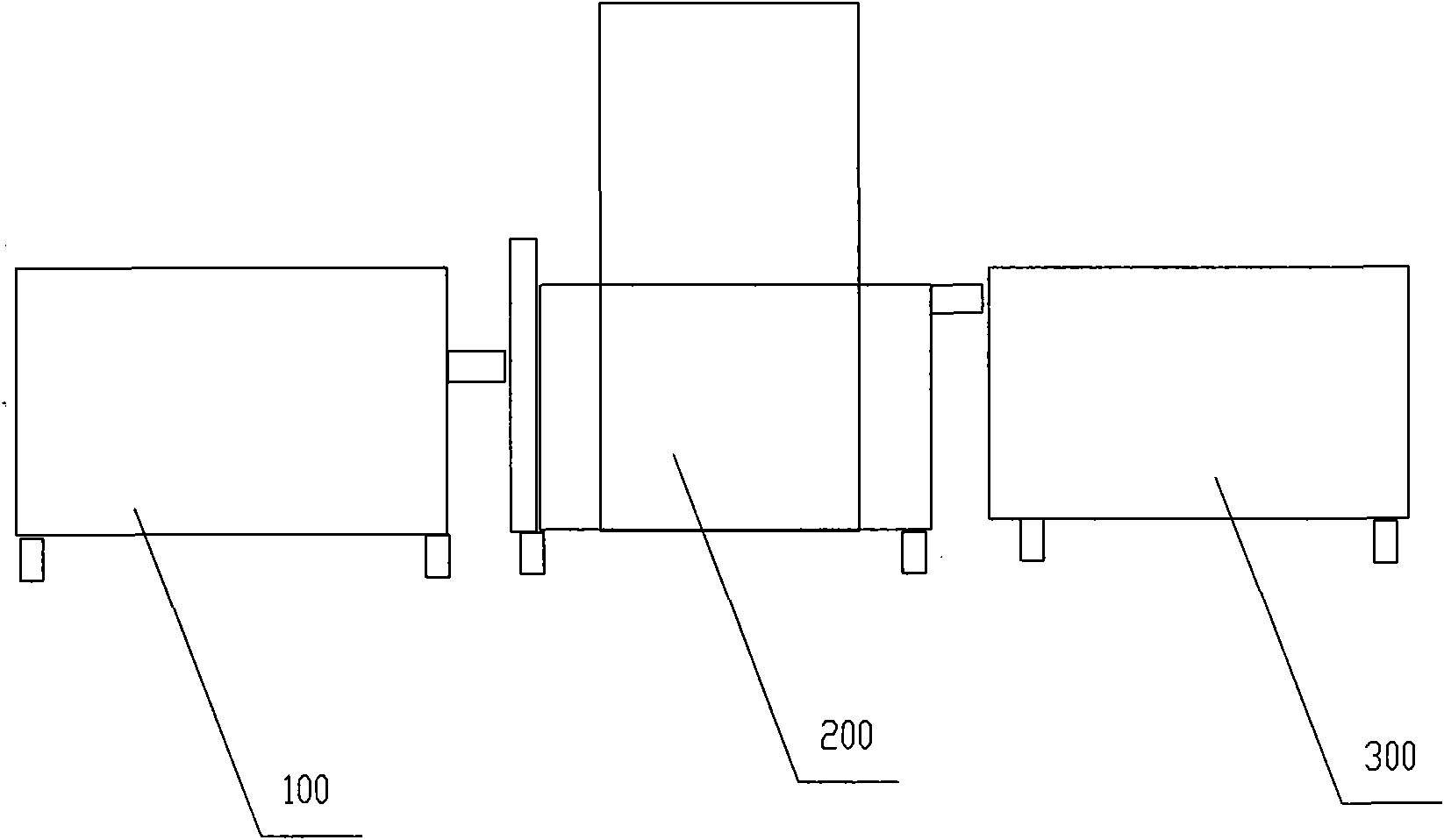

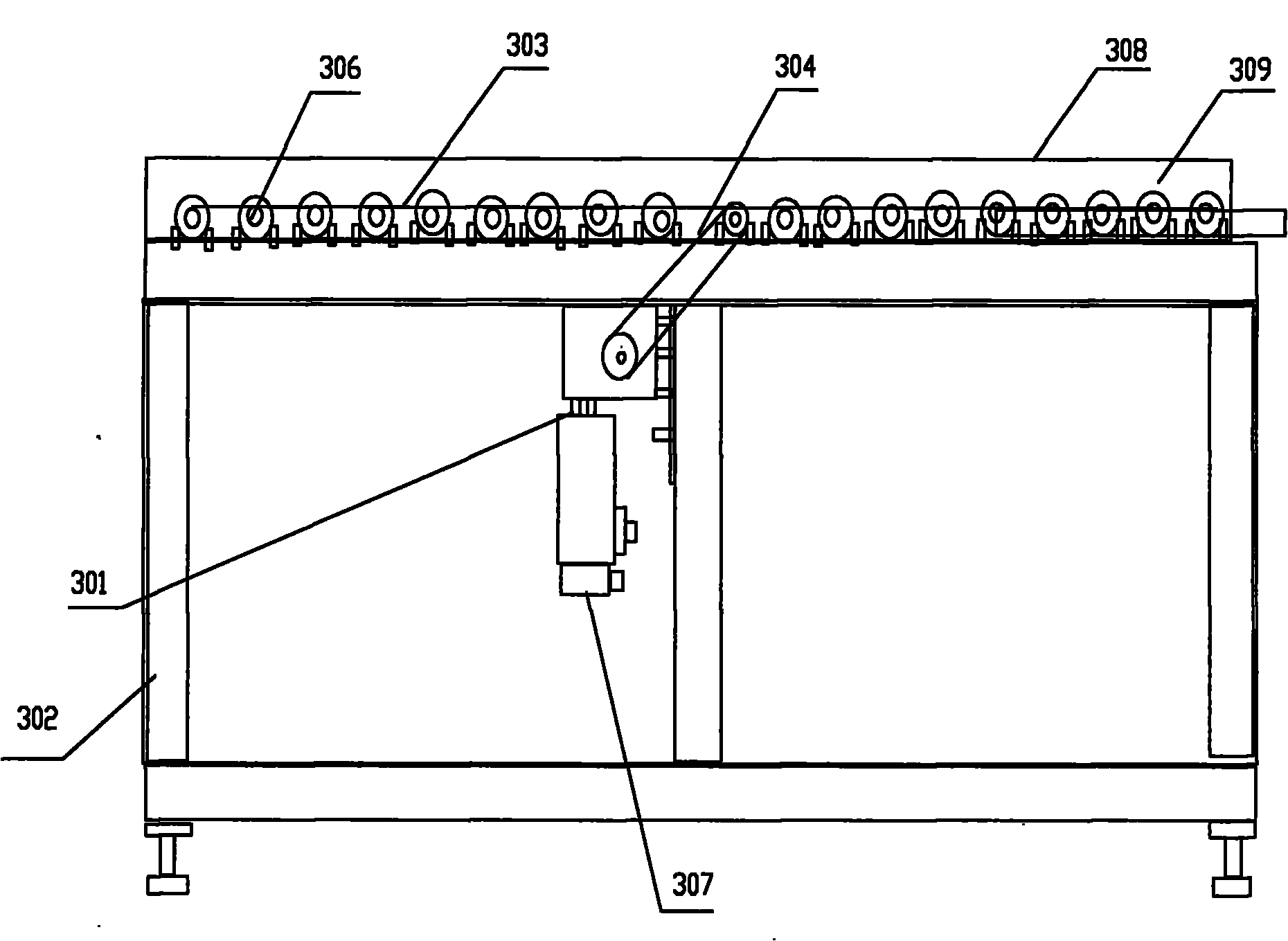

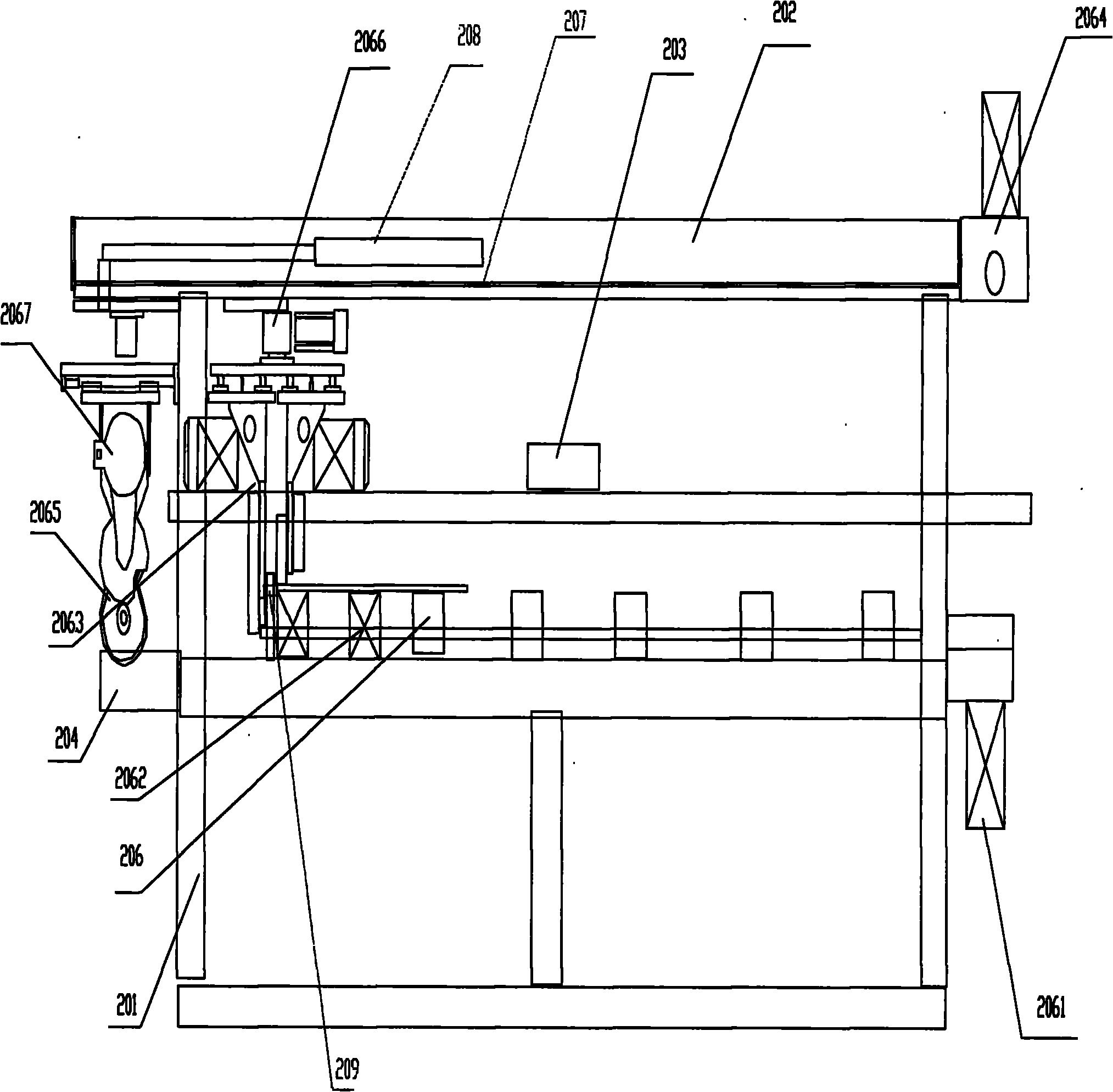

[0024] Embodiment 1: A horizontal glass linear four-sided grinding wheel type edging machine includes a film output system assembly 100, an edging system assembly 200 and a film loading system assembly 300, see eg figure 1 As shown, the upper film system assembly 300, the edging system assembly 200 and the lower film system assembly are connected in sequence 100 in a row, and the distance between them is 30-50mm, wherein the transmission roller 306, The suction cup system assembly 206 in the edging system assembly 200 and the driving roller 106 in the lower film system assembly have the same working height, and the retaining wheel 309 in the upper film system assembly is the same as the retaining wheel 309 in the edging system assembly. Wheel 209 is a straight line.

[0025] Further, the film loading system assembly 300 is composed of a film loading rack assembly 302 , a film loading conveying system assembly 303 and a safety cover 308 . The loading conveying system assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com