Conductive corrugated tube

A corrugated tube and conductive tube technology, applied in conductors, hoses, circuits, etc., can solve the problems of easy deformation and breakage of copper tubes, high cost, low efficiency, etc., to improve power supply reliability, save non-ferrous metals, and widen social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

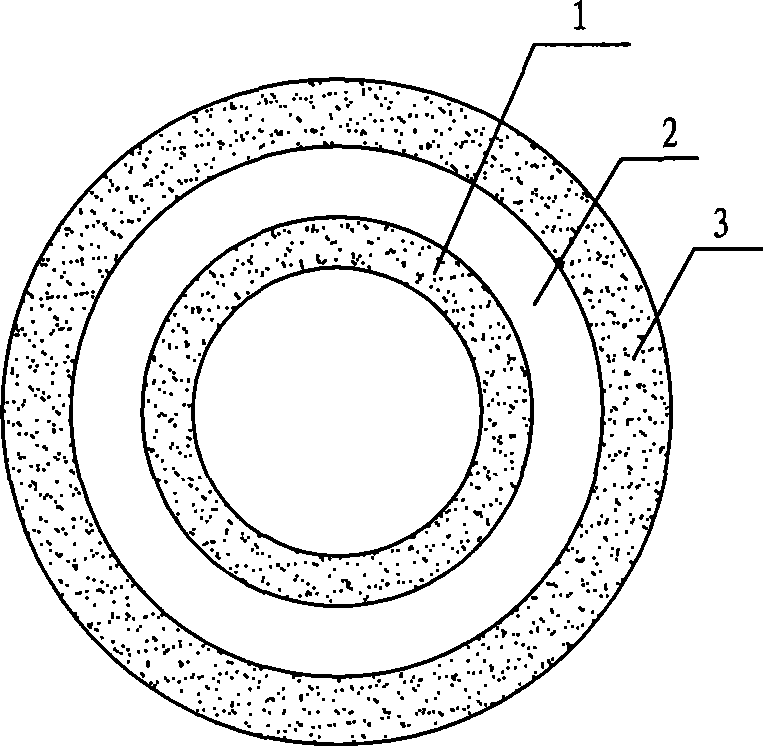

[0028] According to the requirements of the current carrying capacity, one layer of conductive bellows or multi-layer conductive bellows is selected as the wire and cable conductor, for example: the outer diameter of the conductive bellows is Φ50mm, the wall thickness is 2mm, and the cross-sectional area is 300mm 2 Rated current 900A, current density: 3(A / mm 2 ), temperature rise 50k.

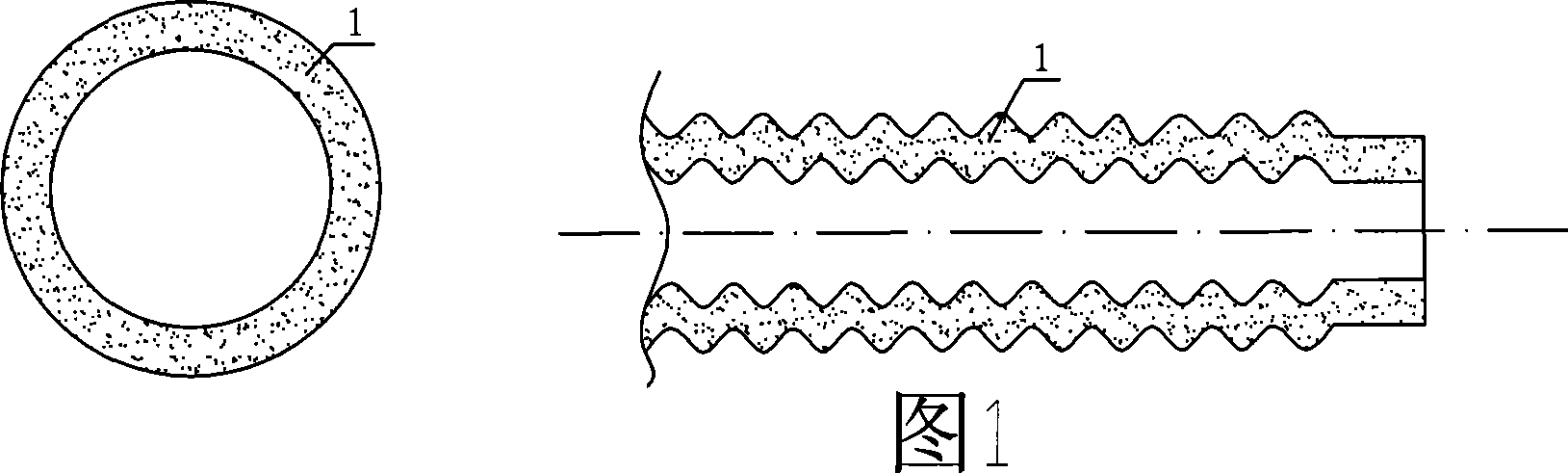

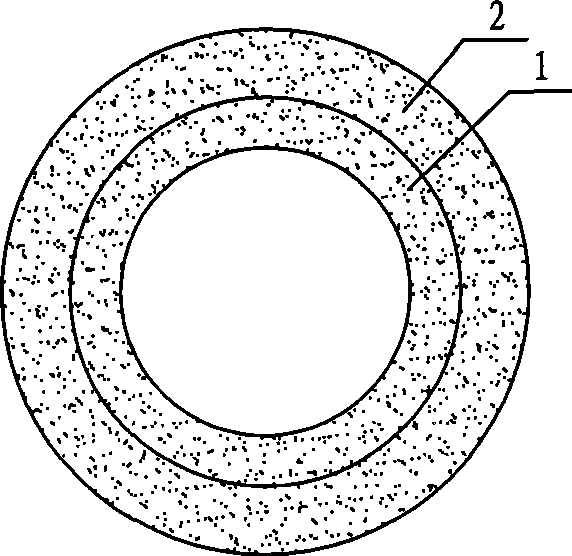

[0029] 1. The method of manufacturing conductive bellows: According to the current carrying capacity requirements, select the appropriate copper strip or aluminum strip (thickness 0.1mm ~ 15mm), use the welded pipe production line to produce the conductive tube first, and use the rolling machine to press the conductive tube into Conductive corrugated pipe (Figure 1); if multi-layer conductive corrugated pipe is required, firstly use the welded pipe production line to produce multi-layer conductive pipe, and use a rolling machine to press the multi-layer conductive pipe into a multi-layer conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com