Overload protecting structure of material pushing mechanism

A push mechanism and overload protection technology, applied in the field of overload protection structures, can solve problems such as increased production cost, deformation and damage, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

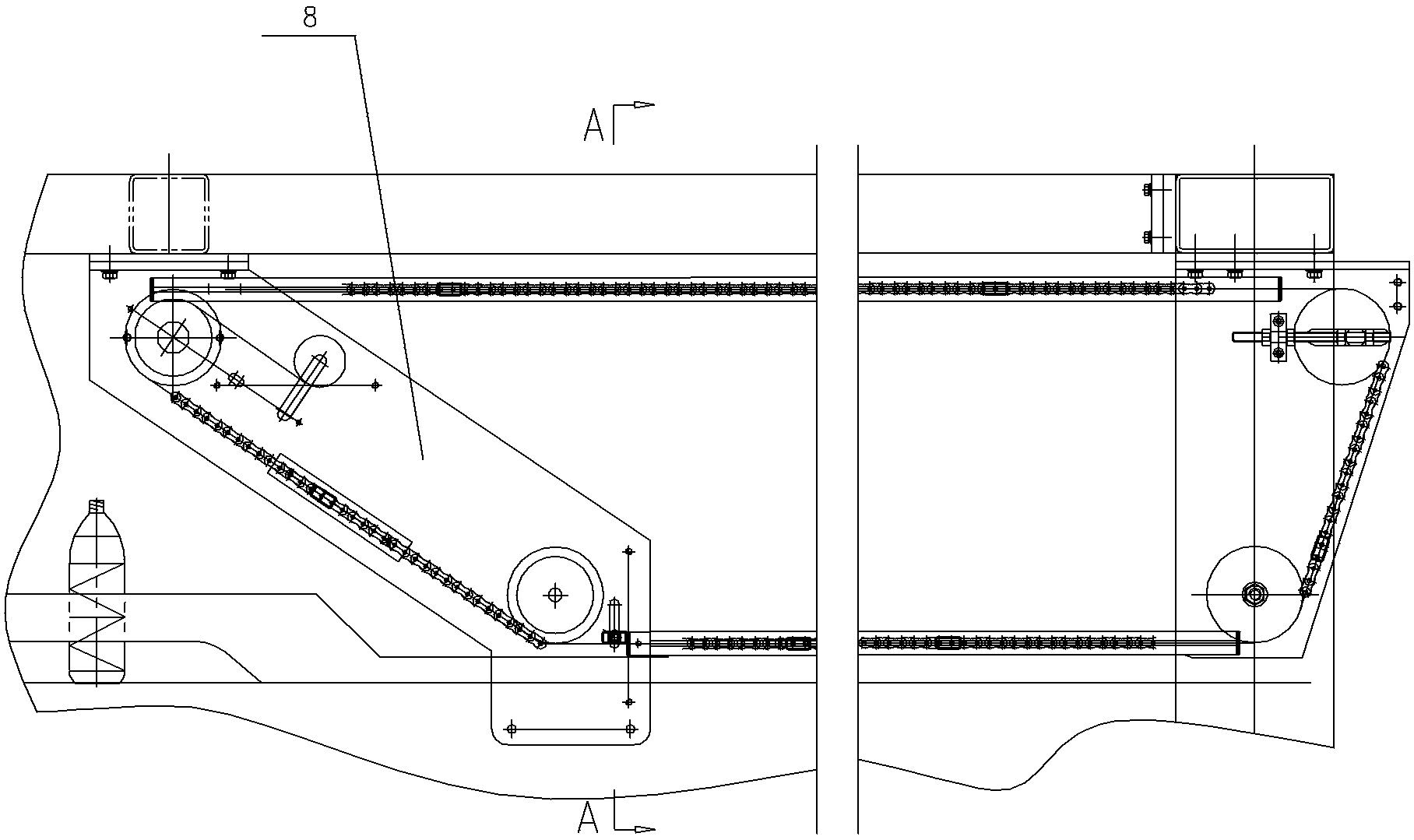

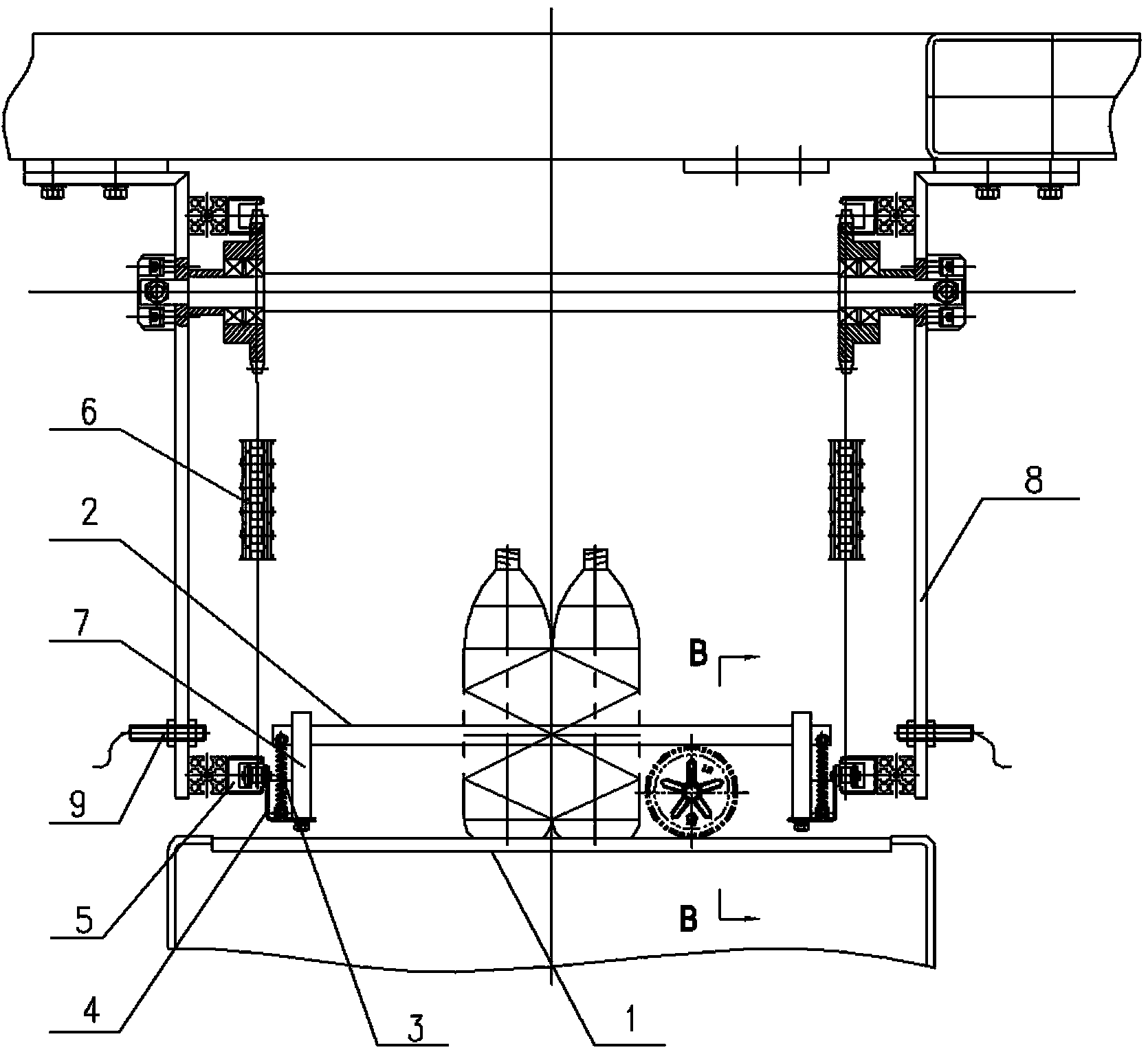

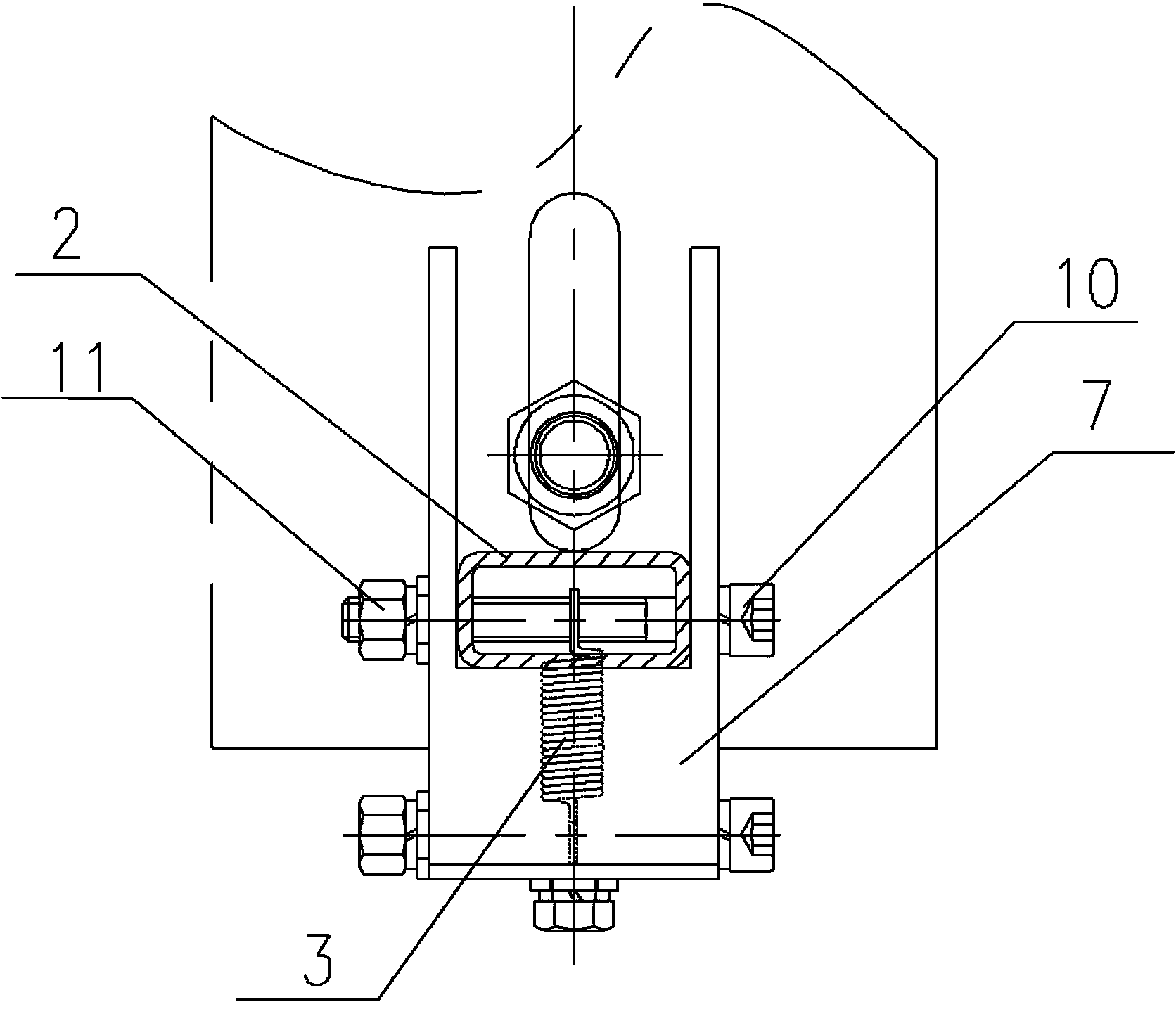

[0012] An overload protection structure of a material pushing mechanism, such as Figure 1 to Figure 4 As shown, it includes the bottle-driving bar 2 arranged on the top of the conveyor belt 1, the two ends of the bottle-driving bar 2 are fixedly connected with one end of the corresponding spring 3 respectively, and the other end of the spring 3 is fixed on the corresponding support seat 4, and the support seat 4 is connected with the corresponding spring 3. The conveyor chain 6 that is installed in the fixed guide groove 5 and can move relative to the fixed guide groove 5 is fixedly connected.

[0013] The two ends of the bottle driving bar 2 that can slide along the guide block 7 are respectively connected with the guide block 7 fixed on the support base 4 .

[0014] On both sides of the conveying chain 6, the protective plate 8 with the fixed guide groove 5 is installed with a photoelectric switch 9. When a bottle is dumped, the bottle driving rod 2 is pressed on the body o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com