Pipeline accompanying-heat cable

A heat tracing cable and pipe technology, applied in the direction of rigid pipe cables, insulated cables, cables, etc., can solve problems such as fire, thermal expansion and contraction coefficients are not the same or not synchronized, local resistivity rises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

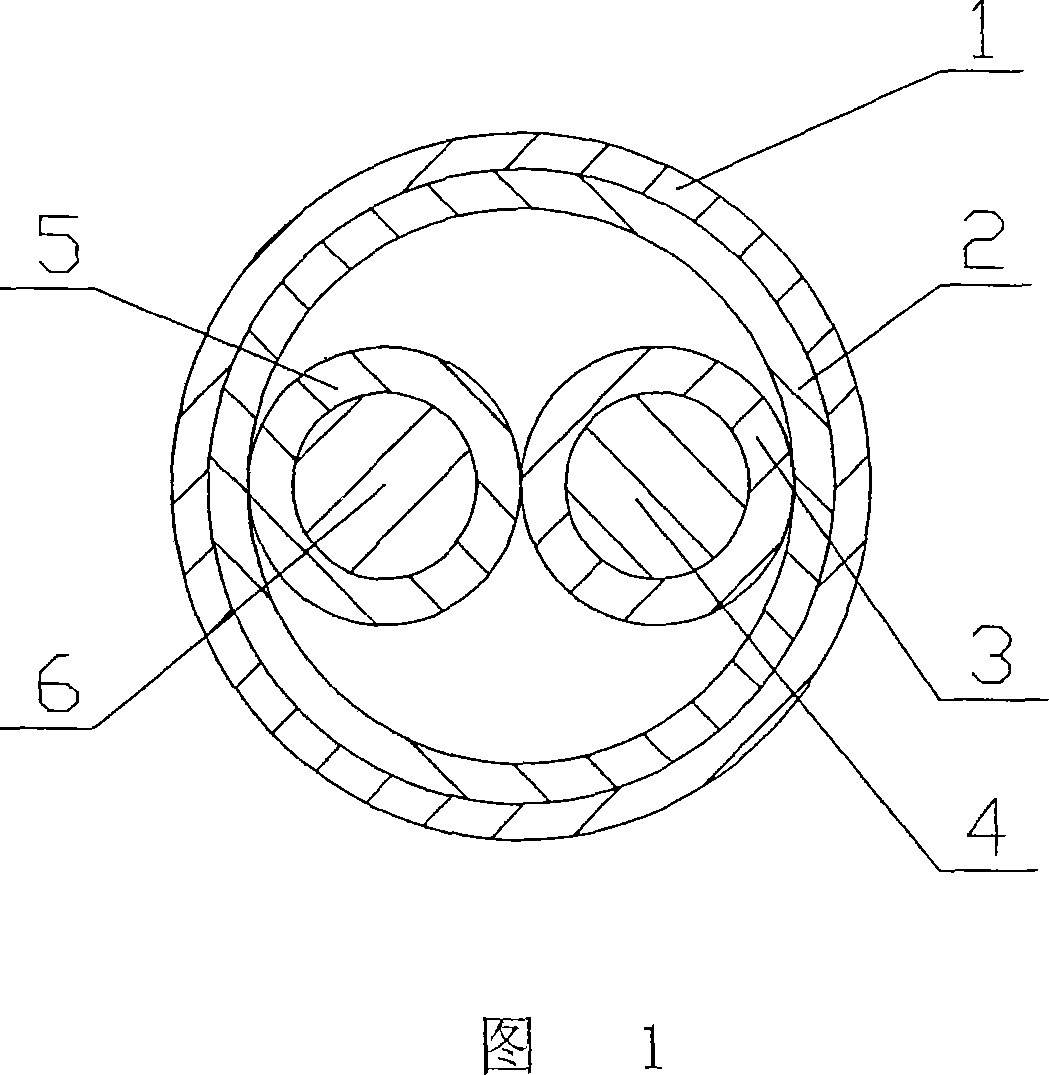

[0009] As shown in FIG. 1 , the carbon fiber 6 is arranged in the carbon fiber insulating layer 5 , the carbon fiber insulating layer 5 is arranged in the outer insulating layer 2 , and the lubricating layer 1 is arranged outside the outer insulating layer 2 .

[0010] A metal insulating layer 3 is also arranged in the outer insulating layer 2 , and a metal conductor 4 is arranged in the metal insulating layer 3 .

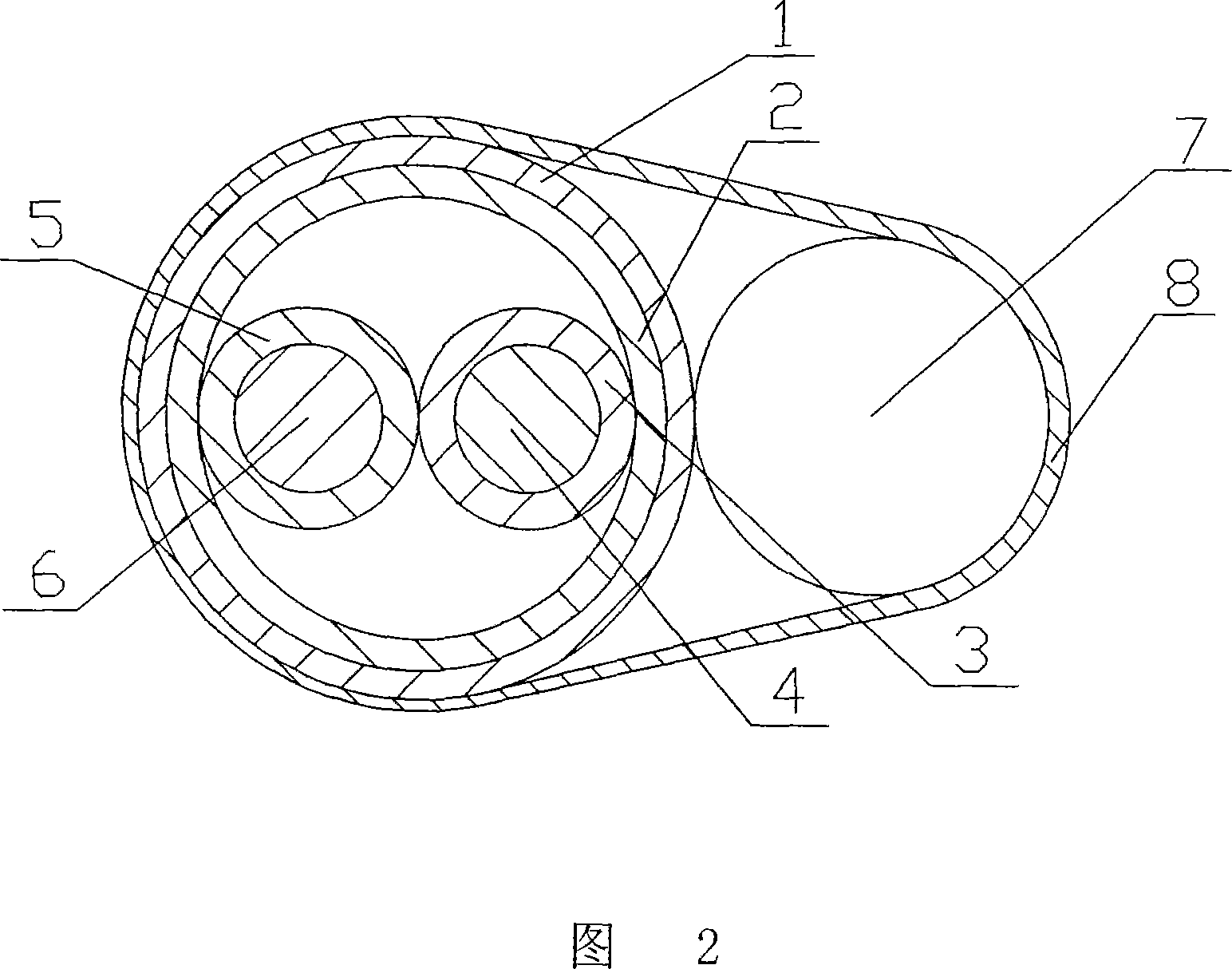

[0011] As shown in Figure 2, put the present invention and the pipeline 7 together, and bind the carbon fiber heating cable or the carbon fiber electric heating cable on the pipeline through various adhesive tape papers with glue or strip materials 8 without glue, A lubricating layer 1 is provided on the outside of the carbon fiber heating cable or carbon fiber electric heating cable, because the friction coefficient is greatly reduced, and the degree of adhesion when the sticky tape paper is adhered is greatly reduced, so when in use, the carbon fiber heating cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com