Insulation thin-wall copper pipe bus

A copper tube and bus bar technology, applied in the field of new inventions, can solve the problems of high cost, waste of copper, heat generation, etc., and achieve the effects of light weight, energy saving, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

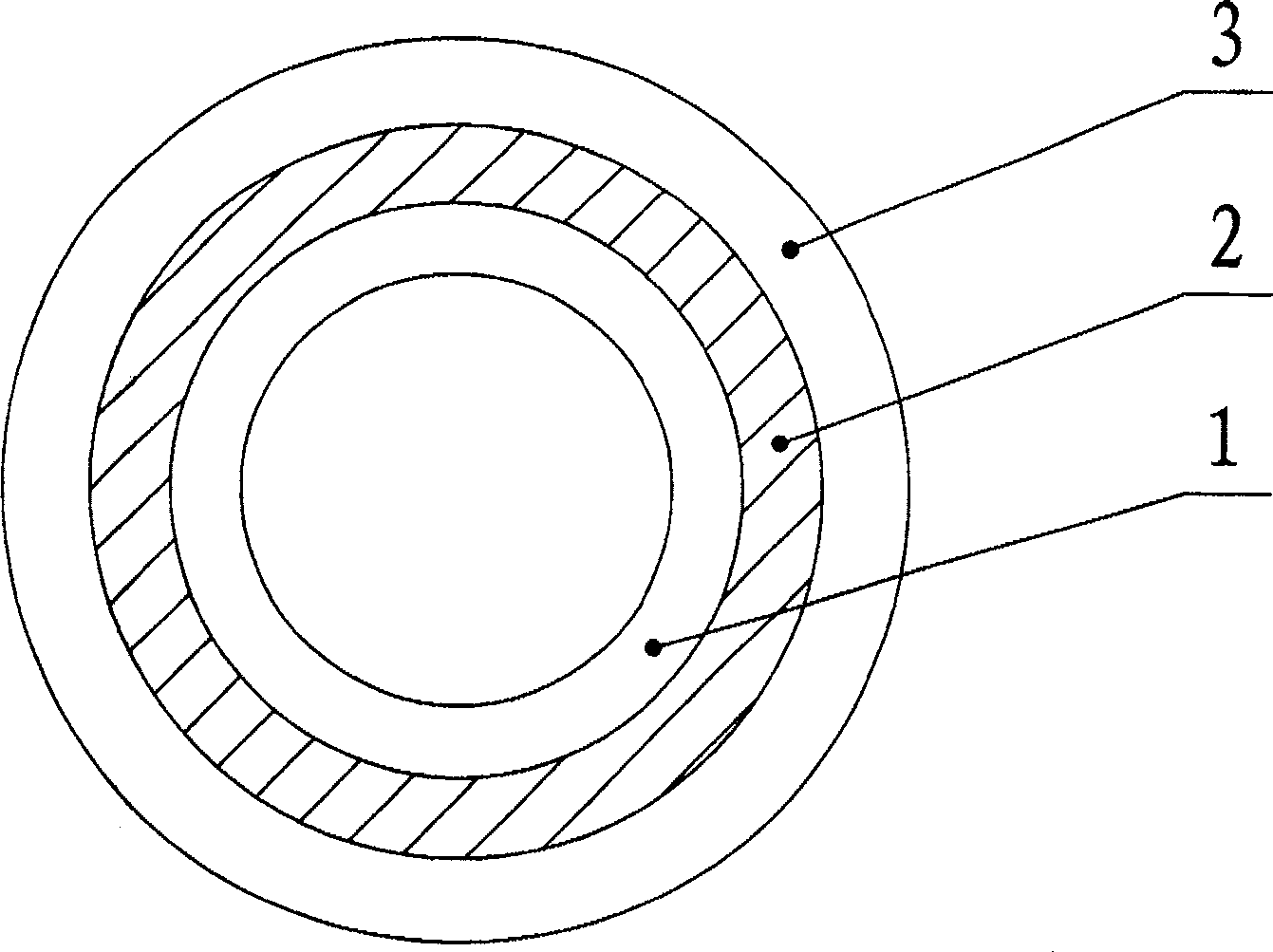

[0029] Attached below figure 1 The specific embodiment of the present invention will be further described.

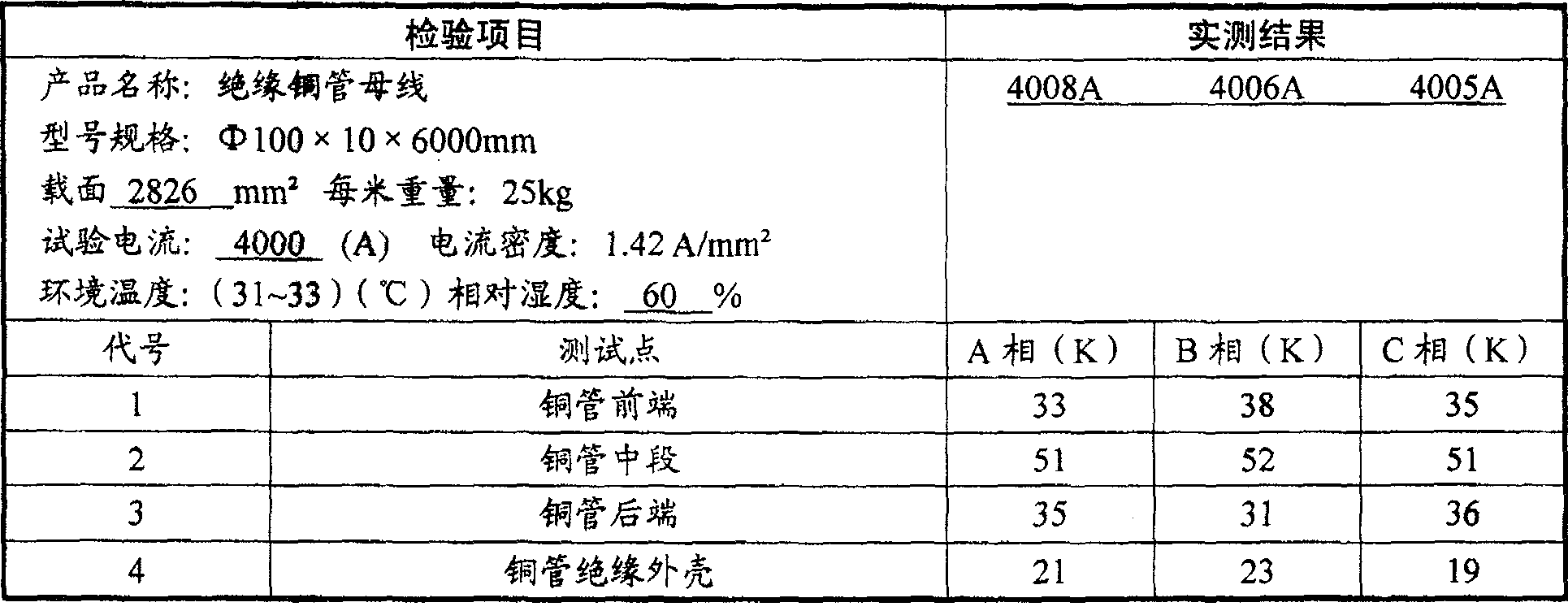

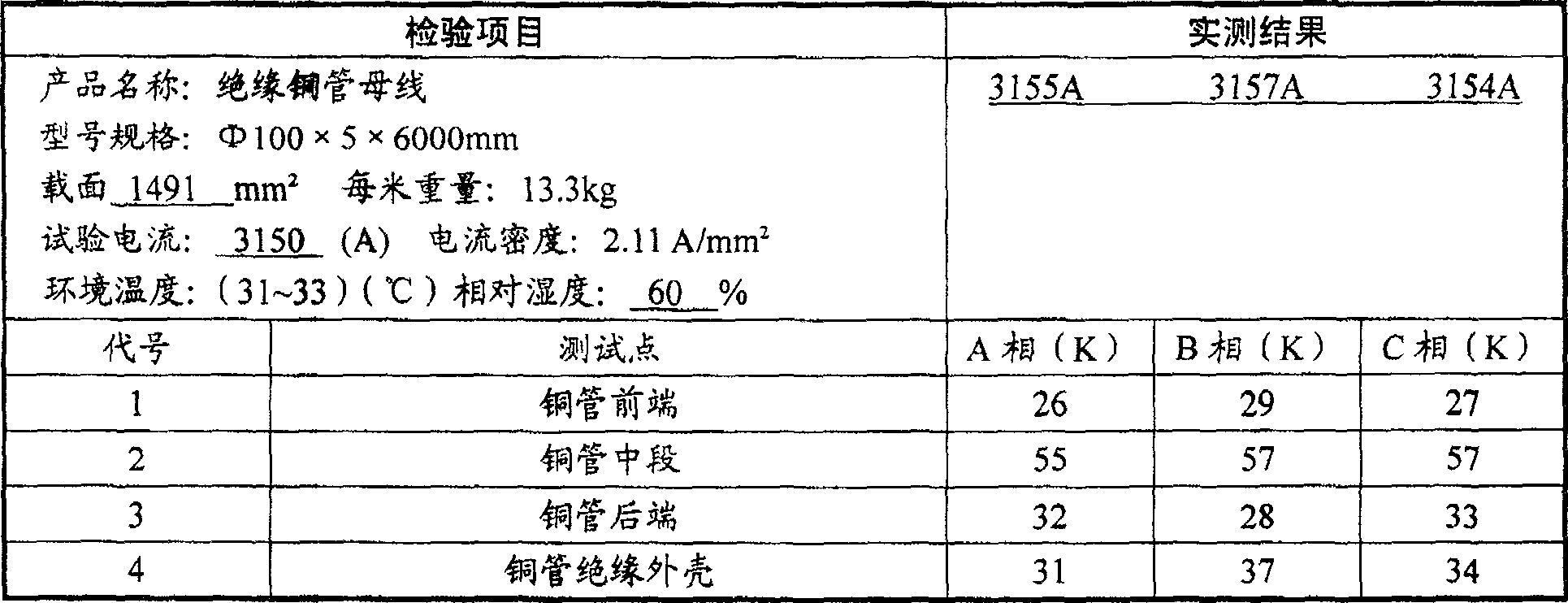

[0030] Such as figure 1 As shown, the insulating thin-walled copper tube bus bar of the present invention, according to the requirement of current carrying capacity, the bus bar adopts thin-walled copper tubes with a thickness below 4mm, and the copper tubes adopt cold drawing, and the specifications are as follows:

[0031] ①The 8000A busbar adopts copper pipes with a wall thickness of 4mm and Φ300mm.

[0032] ②The 6300A busbar adopts copper pipe with a wall thickness of 4mm and Φ240mm.

[0033] ③The 6300A busbar adopts copper pipe with a wall thickness of 3mm and Φ290mm.

[0034] ④The 5000A busbar adopts copper pipe with a wall thickness of 4mm and Φ200mm.

[0035] ⑤The 5000A busbar adopts copper pipe with a wall thickness of 3mm and Φ220mm.

[0036] ⑥The 5000A busbar adopts copper pipes with a wall thickness of 2mm and Φ270mm.

[0037] ⑦The 4000A busbar adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com