Dye waste water treatment method based on membrane technology

A dye wastewater and treatment method technology, applied in the direction of adsorption water/sewage treatment, oxidation water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of long process flow, unstable effluent quality, teratogenicity, etc. To achieve the effect of overcoming the high cost of adsorption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

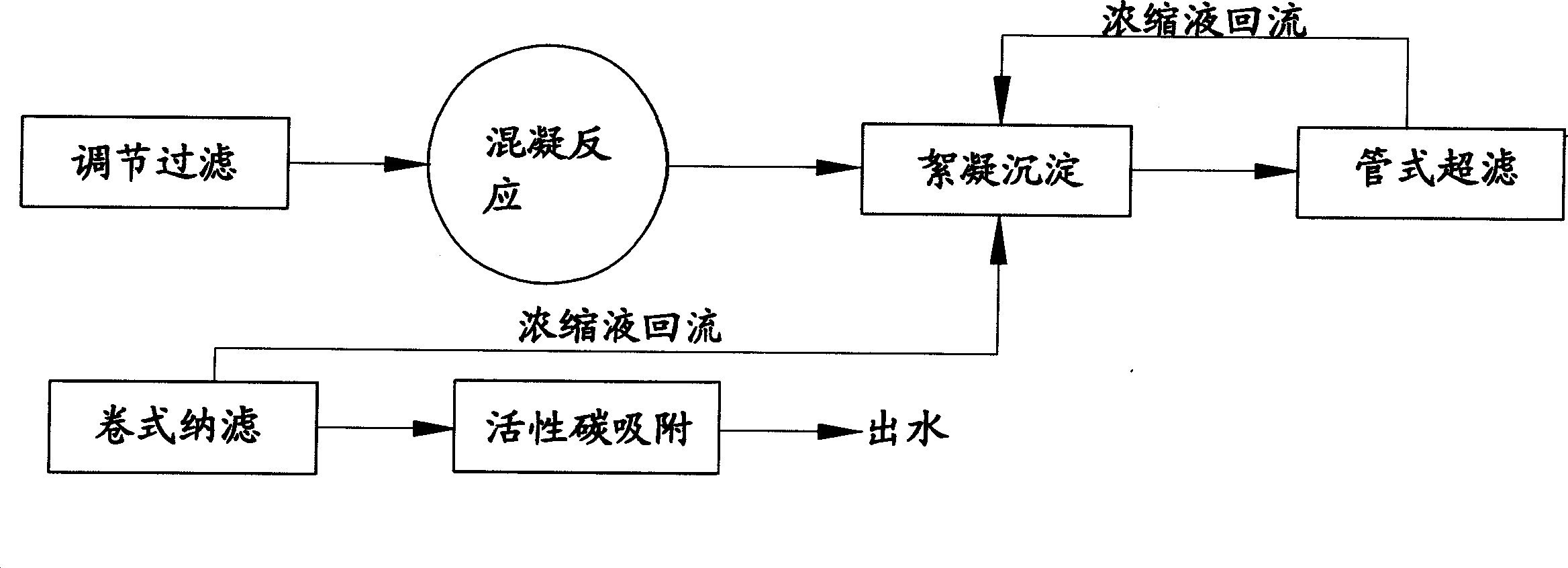

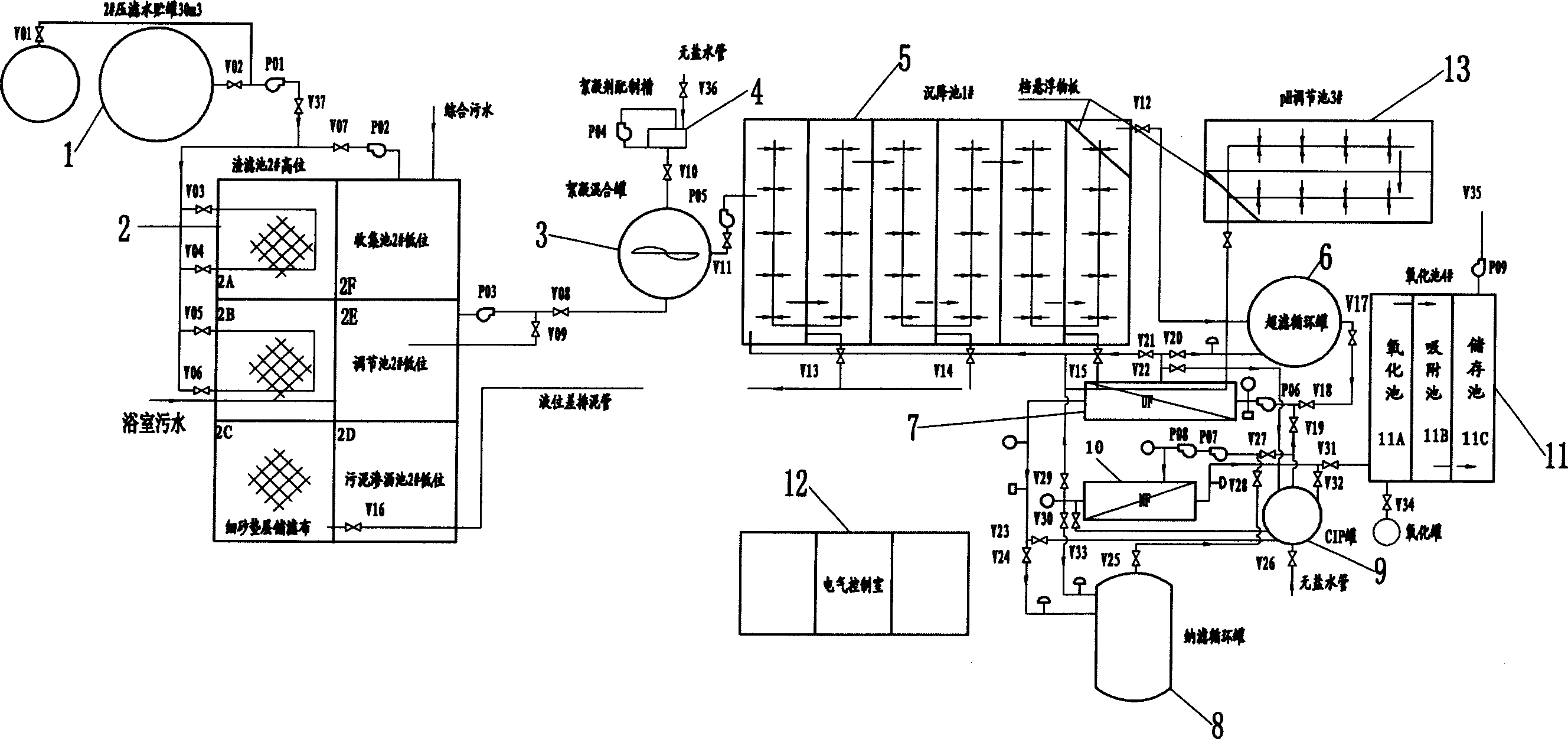

[0030] The following is combined with the flocculation process figure 1 and figure 2 The present invention is further described.

[0031] First analyze the operation steps and process conditions as a whole

[0032] 1. Comprehensive regulation of filtration and wastewater

[0033] 1.1, filter

[0034] The dye waste water and domestic waste water stored in the waste water storage tank are mixed according to the measured ratio, and then filtered through slag filtration to remove the suspended matter, and the filtrate is stored in the waste water comprehensive pool to obtain comprehensive waste water.

[0035] 1.2. Comprehensive adjustment

[0036] Test the pH and COD value of the comprehensive wastewater. If necessary, add lye or low COD wastewater to adjust the pH value and COD. The pH should be controlled within the range of 6-9, and the COD should be controlled within 4000-8000mg / L. Take an appropriate amount of comprehensive wastewater, mix it with three different flocc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com