Fracturing well site layout system

A fracturing and layout technology, applied in wellbore/well components, production fluids, AC network circuits, etc., can solve the problems of low output power of electric fracturing equipment, complicated power supply wiring, and long wiring time. Achieve the effect of small footprint, simple structure and saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

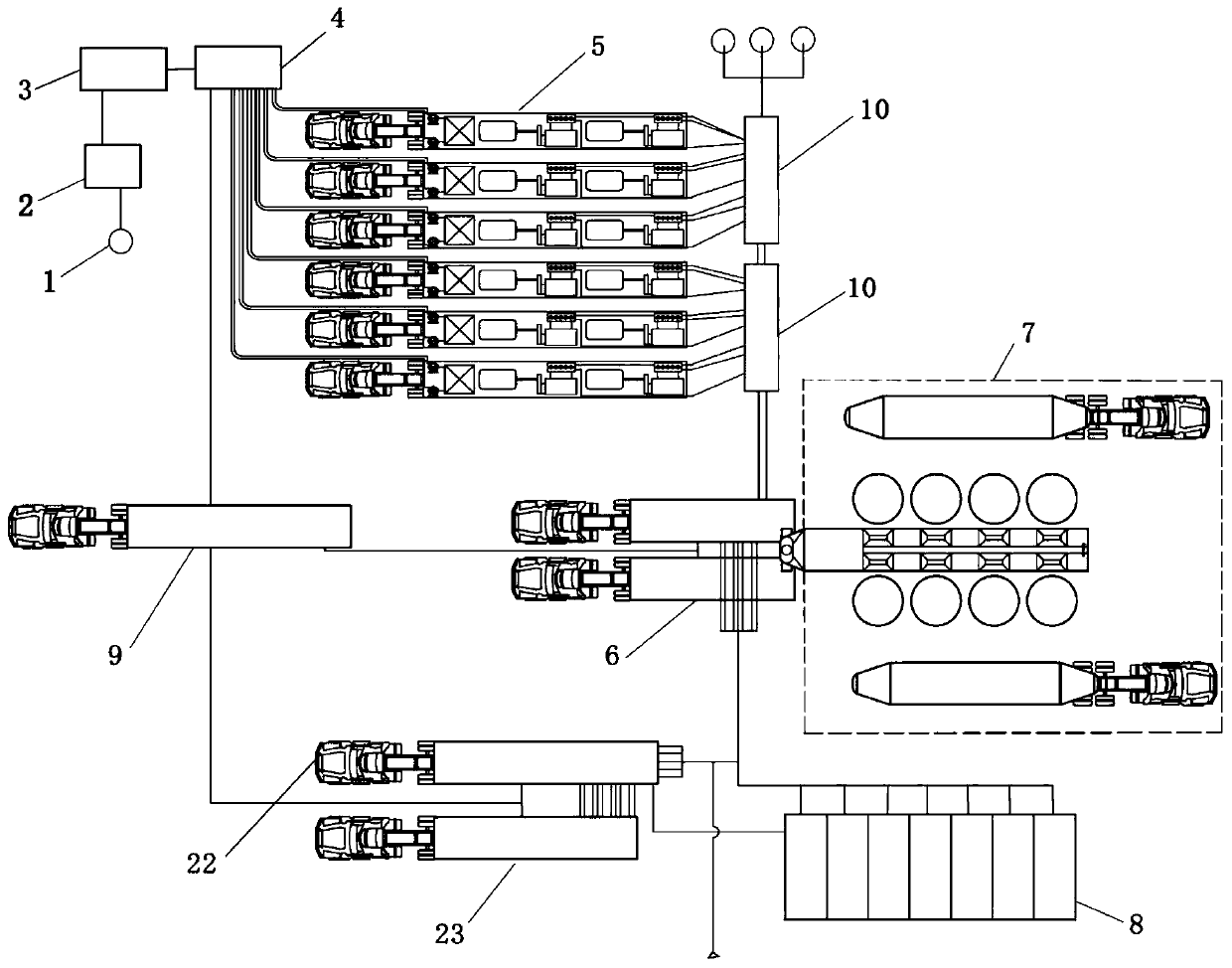

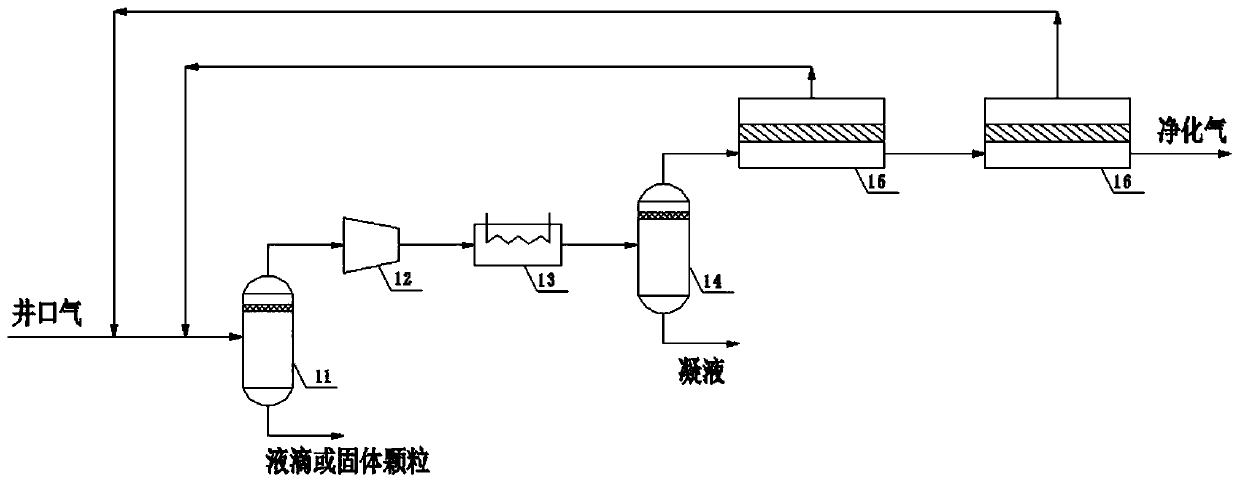

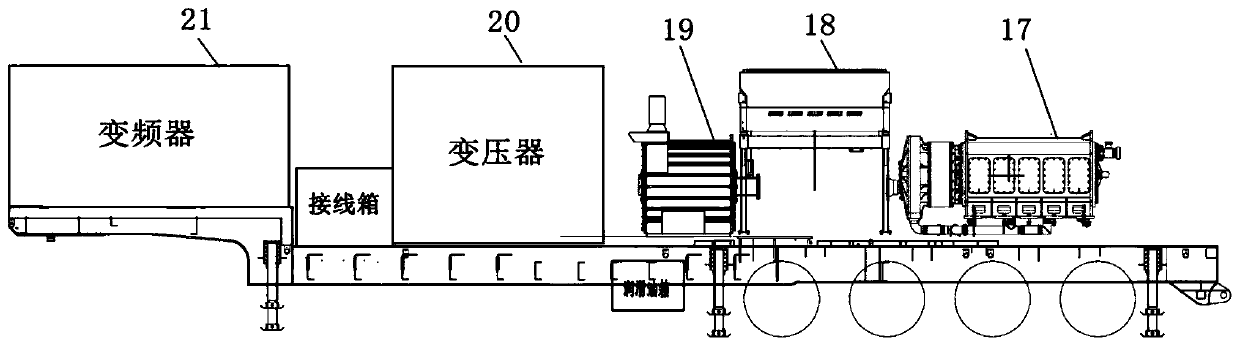

[0019] Such as Figures 1 to 3 As shown, a fracturing well site layout system includes gas source 1, processing equipment 2, power supply system 3, power distribution system 4, electric drive fracturing equipment 5, electric drive sand mixing equipment 6, sand supply equipment 7, Liquid supply equipment 8, instrument equipment 9, high and low pressure manifolds 10, the gas source 1 is processed by the processing equipment 2 to provide the fuel required for power generation for the power supply system 3, and the power supply system 3 respectively drives the electric power supply through the power distribution system 4 Drive fracturing equipment 5 and electric drive sand mixing equipment 6, sand supply equipment 7 provides electric drive sand mixing equipment 6 with fracturing sand required for mixing, and liquid supply equipment 8 provides electric drive sand mixing equipment 6 with required liquid , the output end of the electric drive sand mixing equipment 6 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com