Flow ultracapacitor

a technology of ultracapacitors and ultracapacitors, which is applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, transportation and packaging, etc., can solve the problems of not being economically feasible, not counting the cost of modules and system integration, and existing commercial ultracapacitors costing $14,800/kwh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

Flow Device

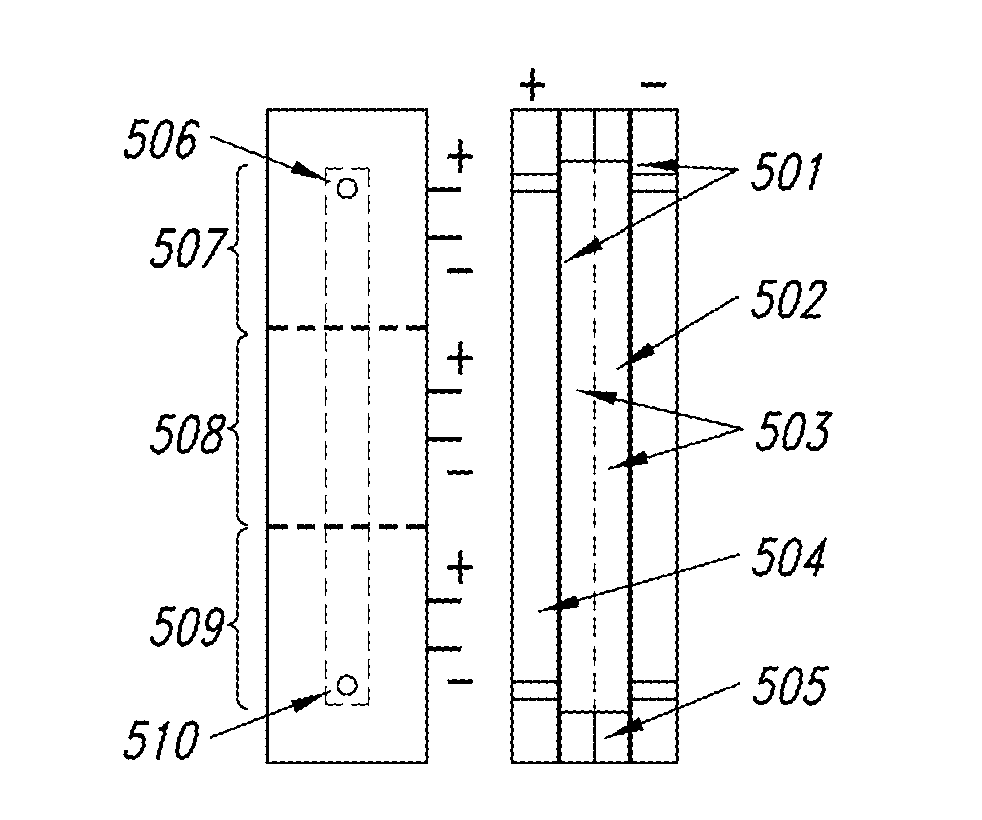

[0134]A flow device was prepared as illustrated in FIG. 5. The device comprised a carbon electrode material, electrolyte (TEA TFB), current collectors 501, an inert porous separator 502, charge channels 503, an outer structure 504 and gaskets 505. Studies conducted with this device indicate that the electrode material becomes charged as it flows through the device. During operation of the device, the electrode suspension moved from an inlet 506 in zone 1507 through zone 2508 to an outlet 510 in zone 3509. Measurements were taken in each zone as the electrode suspension flowed through the electrochemical cell. The voltage was held at 2V with a relatively steady current and electrode flow was initiated at ˜940 seconds. FIG. 6 shows that the current requirement of Zone 1 increased immediately with zones 2 and 3 lagging in current accepting capability until fresh—uncharged—electrode material arrived in the respective zones. The charged electrode suspension was captured into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com