Endoscope assemblies having working channels with reduced bending and stretching resistance

a technology of endoscope and working channel, which is applied in the field of endoscope assemblies with working channel with reduced can solve the problems of high friction coefficient, inability of medical instruments to progress inability to control the movement of medical instruments through the working channel, so as to reduce the bending and stretching resistance of the assembly, reduce the tension on the articulation control cable, and reduce the friction within the working channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

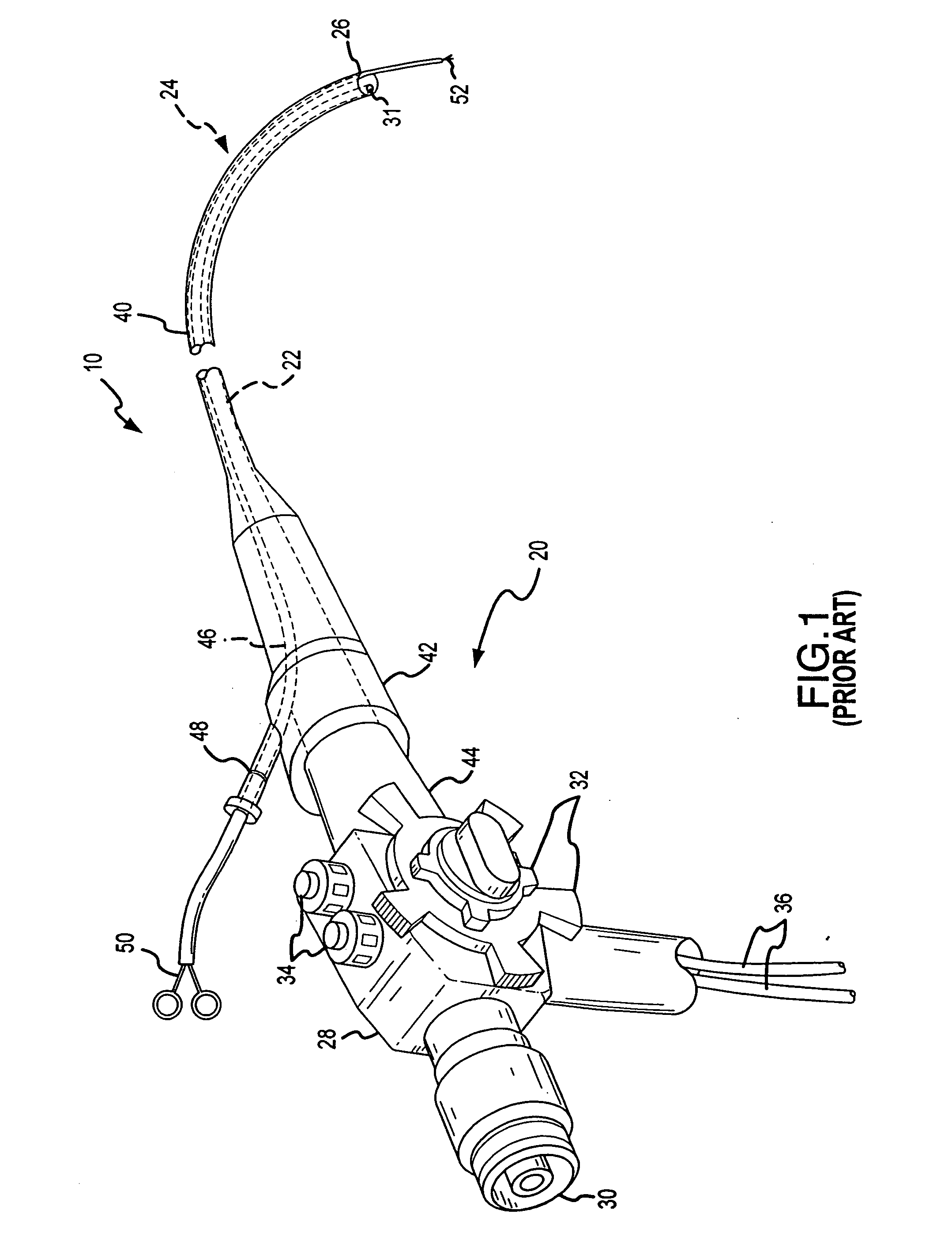

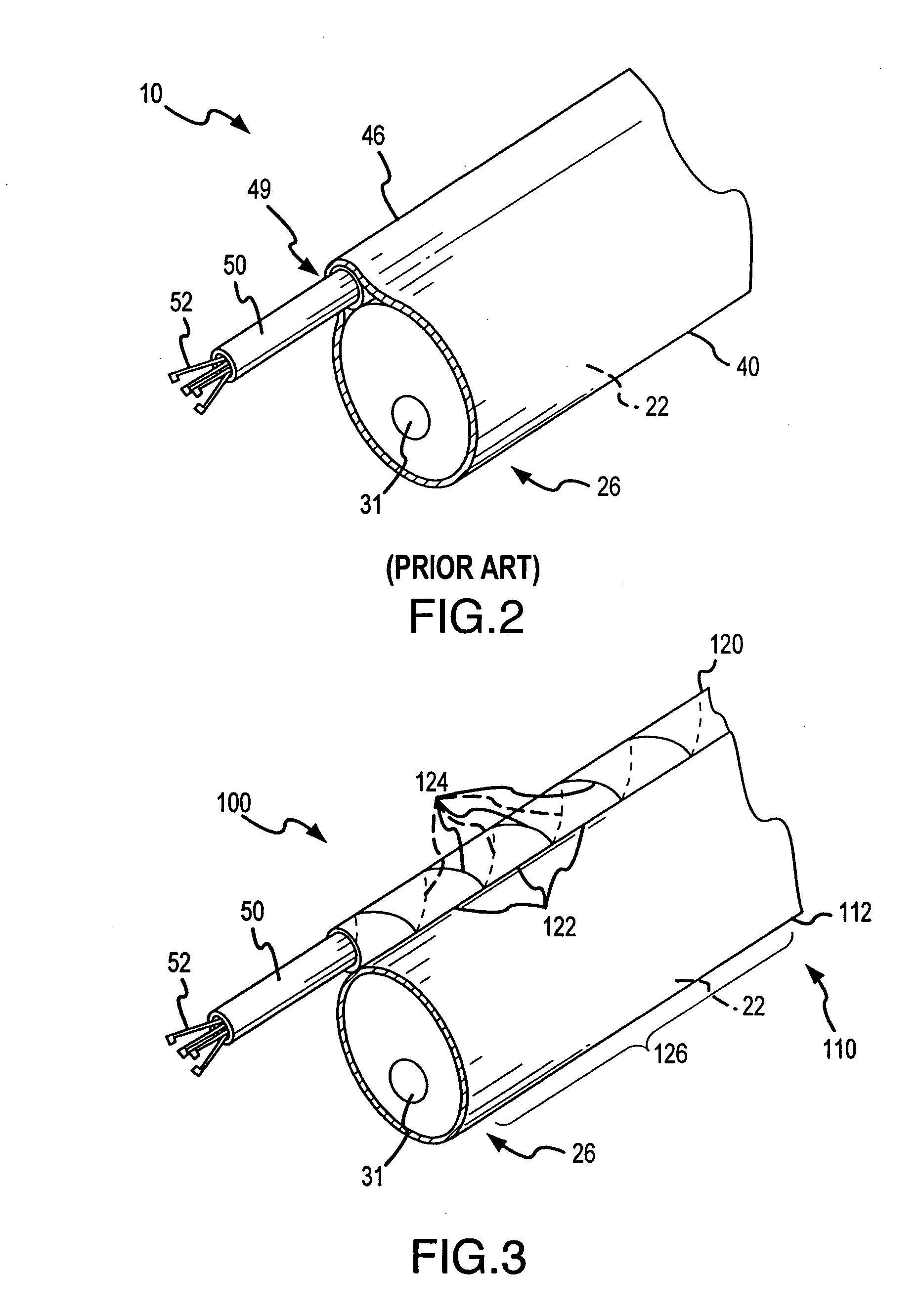

[0039] The present invention is directed toward endoscopic sheath apparatus and methods, and more specifically, to sheath assemblies having working channels with reduced bending and stretching resistance. Many specific details of certain embodiments of the invention are set forth in the following description and in FIGS. 3-24 to provide a thorough understanding of such embodiments. One skilled in the art, however, will understand that the present invention may have additional embodiments, or that the invention may be practiced without several of the details described in the following description.

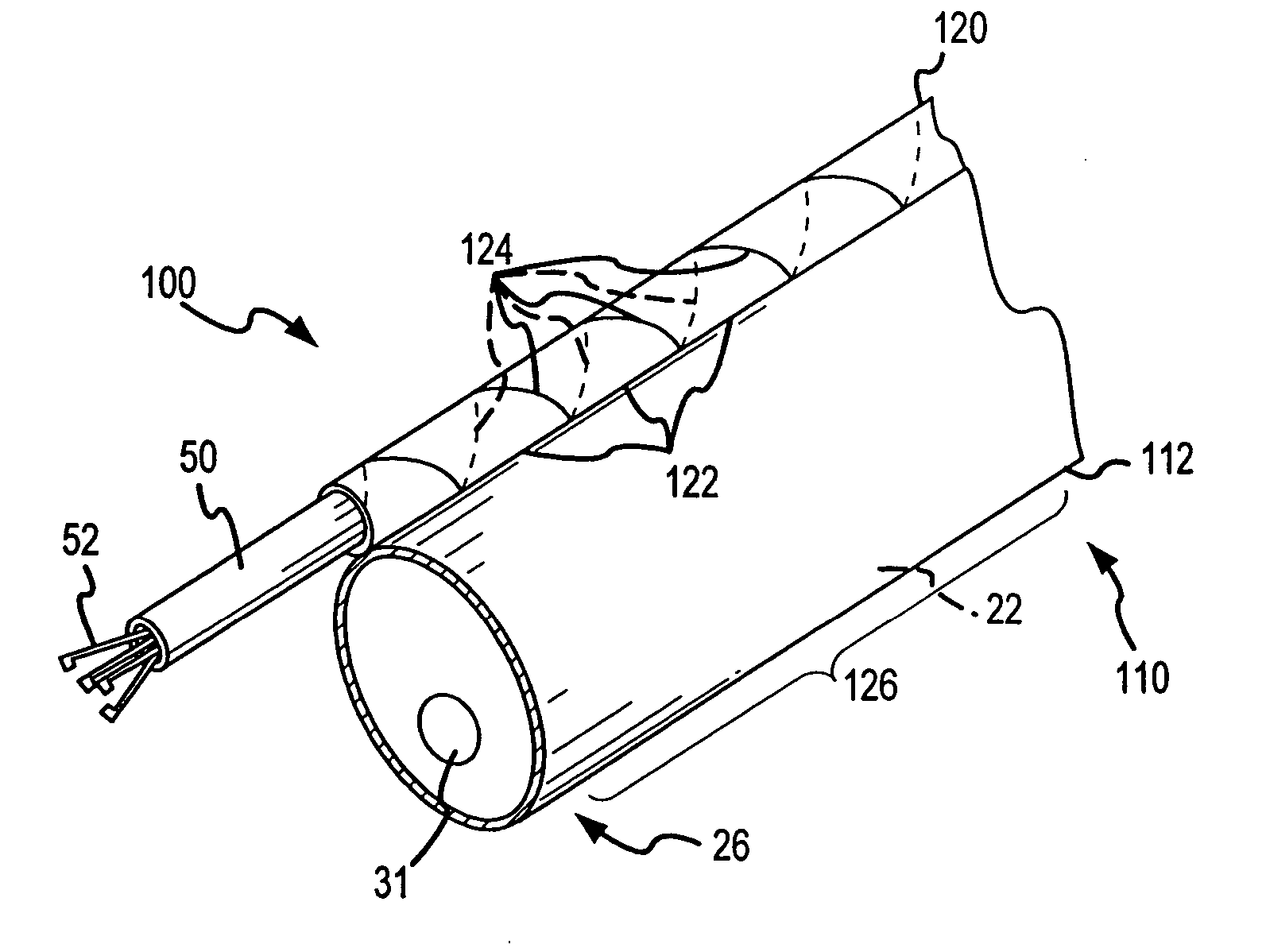

[0040]FIG. 3 is a partial isometric view of an endoscope assembly 100 in accordance with an embodiment of the invention. In this embodiment, the endoscope assembly 100 includes a sheath 110 having a tubular body portion 112 that at least partially encapsulates the insertion tube 22 of the endoscope 10 (FIG. 1), and a working channel 120 attached to an outer surface of the tubular body porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com