Method for manufacturing window plug holes at two sides during PCB (Printed Circuit Board) resistance welding

A technology of PCB board and manufacturing method, which is applied in the direction of electrical connection formation of printed components, can solve the problems of punching through plug holes, vomiting oil, etc., and achieve the effect of improving the punching through of plug holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

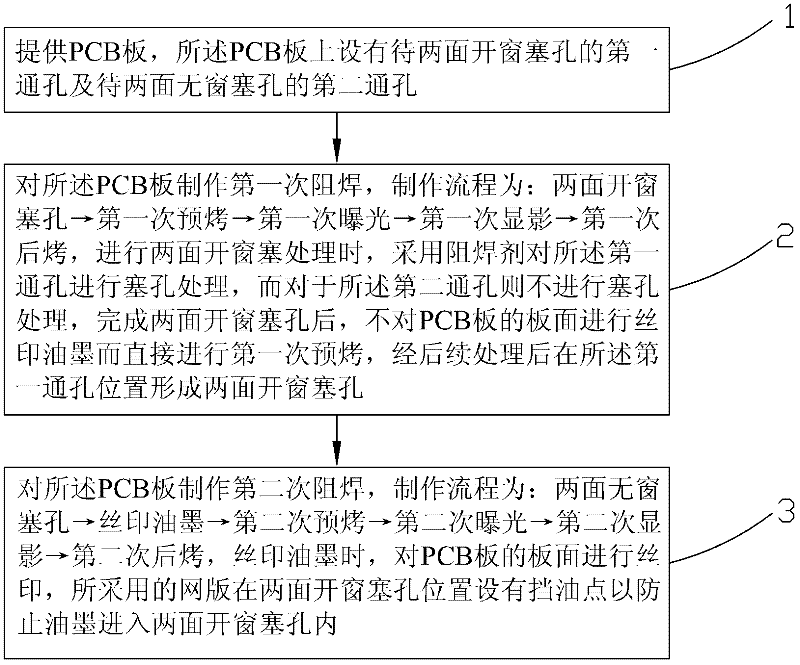

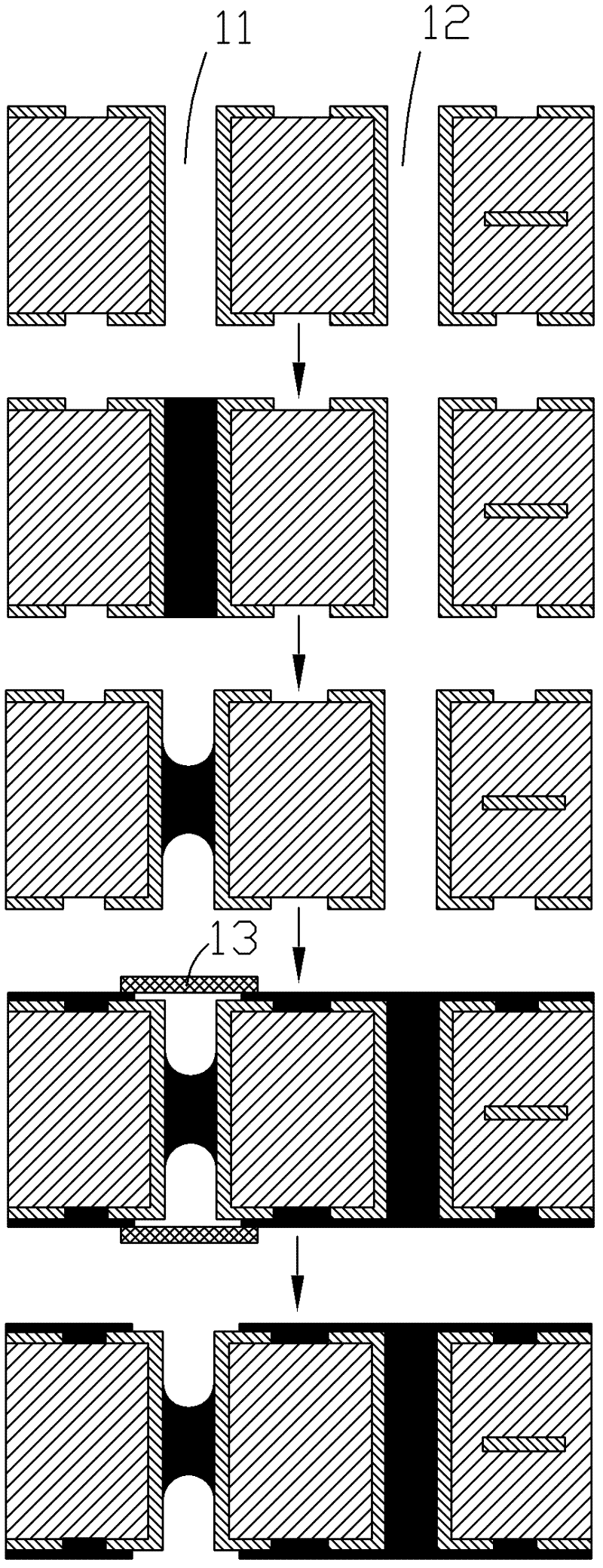

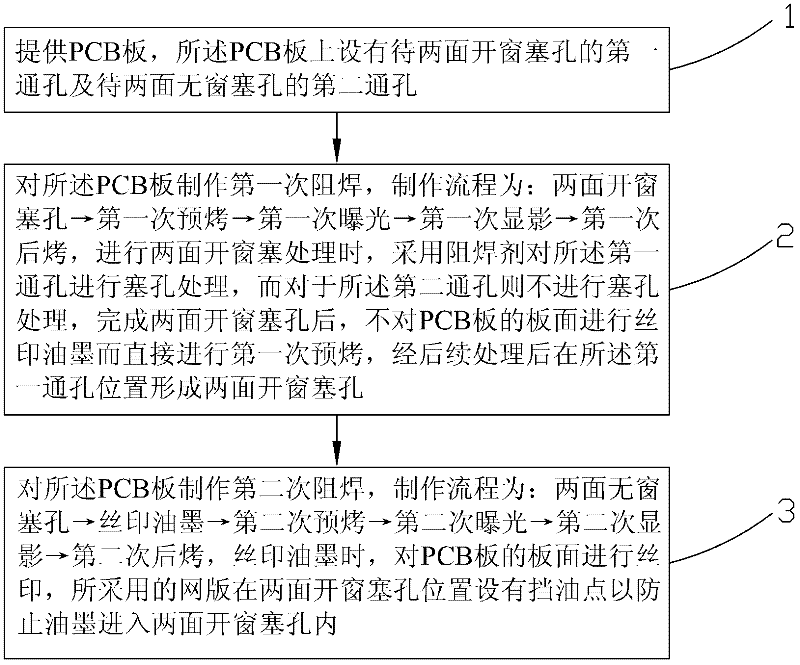

[0017] Such as figure 1 and figure 2 As shown, the manufacturing method of opening the window plug hole on both sides of the PCB board solder resistance of the present invention comprises the following steps:

[0018] Step 1: Provide a PCB board, and the PCB board is provided with a first through hole 11 to be opened with windows on both sides and a second through hole 12 to have no window plug holes on both sides;

[0019] Step 2: Make the first solder resist on the PCB board. The production process is: open the window plug hole on both sides → the first pre-baking → the first exposure → the first development → the first post-baking, and perform double-sided opening During the window plug treatment, the first through hole 11 is plugged with solder resist, but the second through hole 12 is not plugged. After the window plug holes are opened on both sides, the PCB board The first pre-baking is directly carried out with screen printing ink on the surface, and after subsequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com