Quality control device and method for resistance spot welding

A quality control method, resistance spot welding technology, applied in resistance welding equipment, welding power supply, manufacturing tools, etc., can solve the problems of unobvious dynamic resistance, unrealistic detection, unsuitable for spot welding quality control of different materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

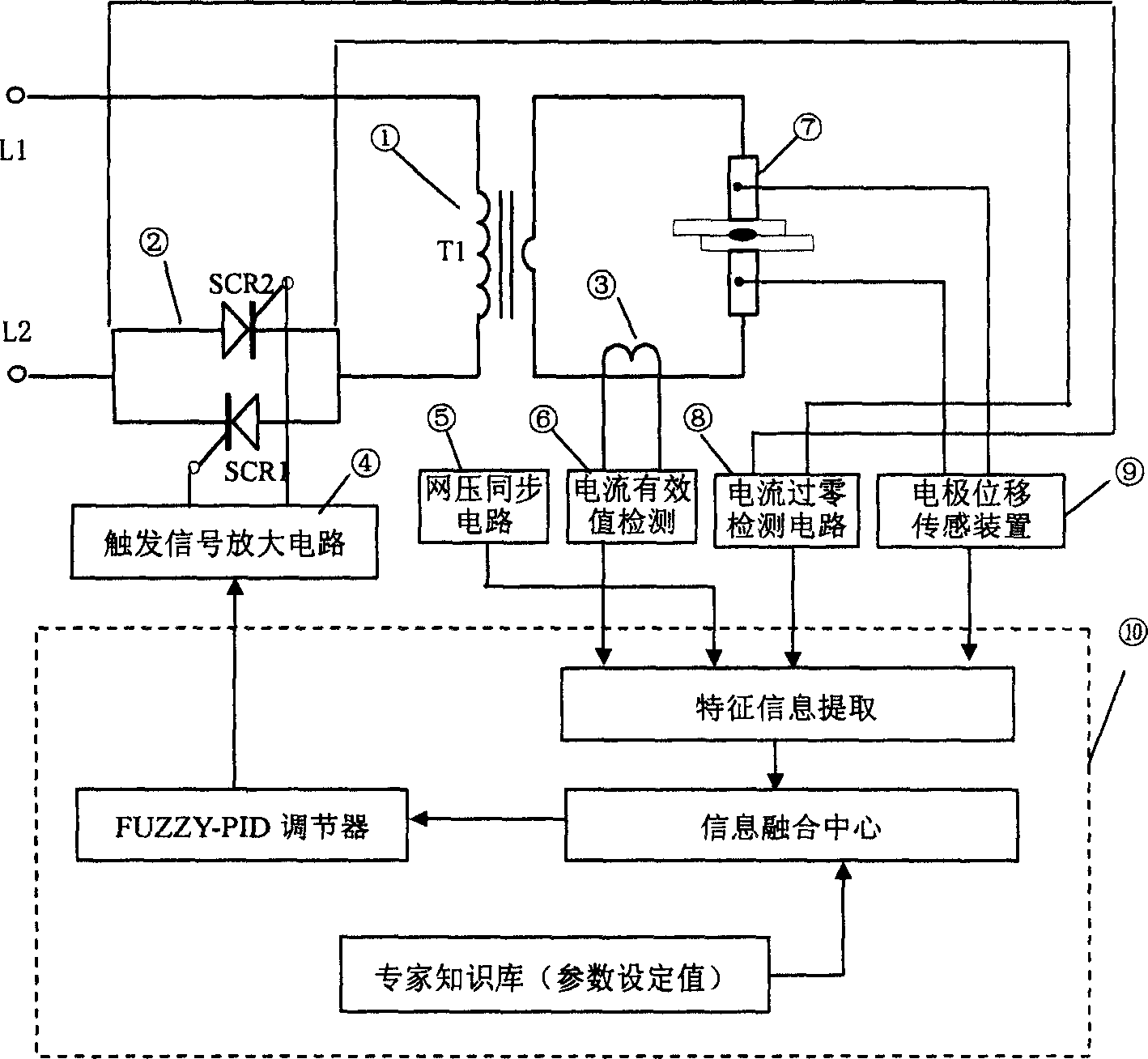

[0061] Such as figure 1 As shown, the resistance spot welding quality control device of the present invention includes a transformer 1, an anti-parallel thyristor 2, a current sensor 3, a trigger signal amplification circuit 4, a network voltage synchronization circuit 5, a current effective value detection circuit 6, an electrode displacement sensor probe 7, A current zero-crossing detection circuit 8 , an electrode displacement sensor 9 , and a single-chip microcomputer control system 10 . The input voltage of the device adopts single-phase 380V power frequency alternating current, and the output is connected to the welding workpiece.

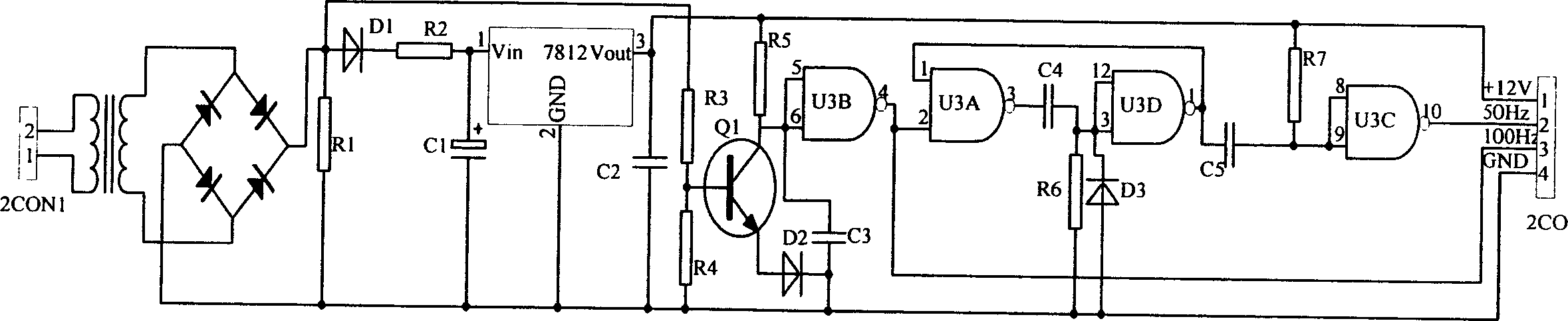

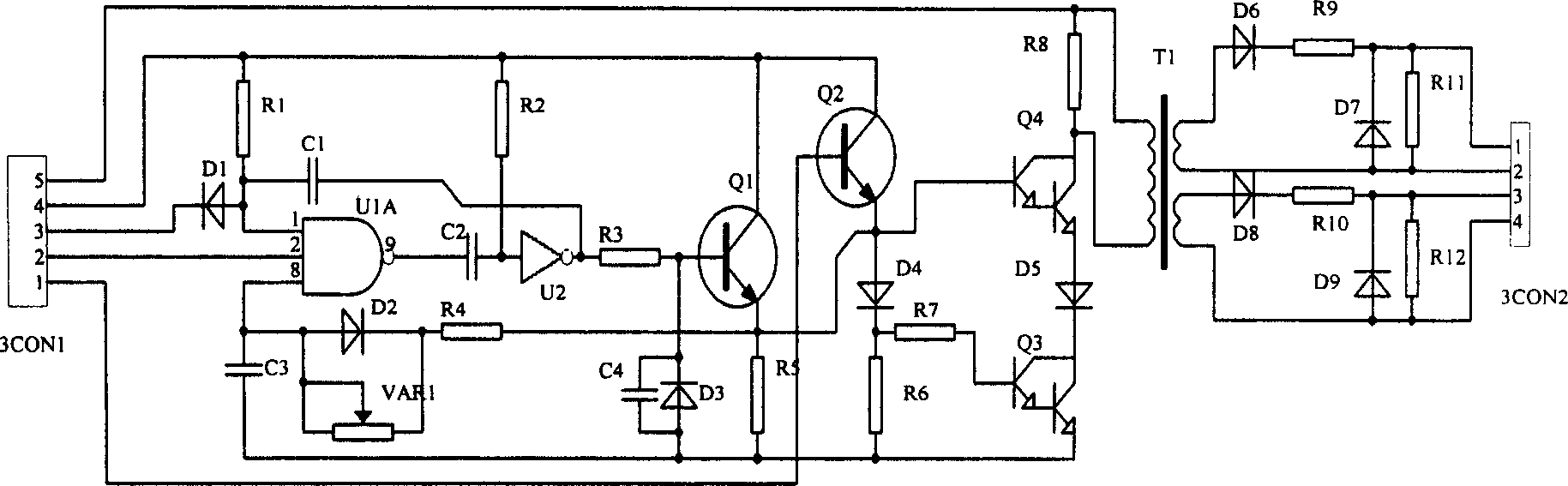

[0062] The circuit connection is: the 1st and 2nd pins of the connector 2CON1 in the network voltage synchronous circuit are respectively connected with the L1 and L2 of the transformer (1); the 1st pin of the connector 2CON2 in the network voltage synchronous circuit is connected with the current zero-crossing detection circuit Pin 1 of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com