Omni-directional bridge detection machine

A detection machine, an all-round technology, applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve the problems of signal shielding and difficult operation, difficult bridge inspection work, and large bridge inspection vehicles, etc., to achieve Complete bridge detection information, simple and fast detection method, saving design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

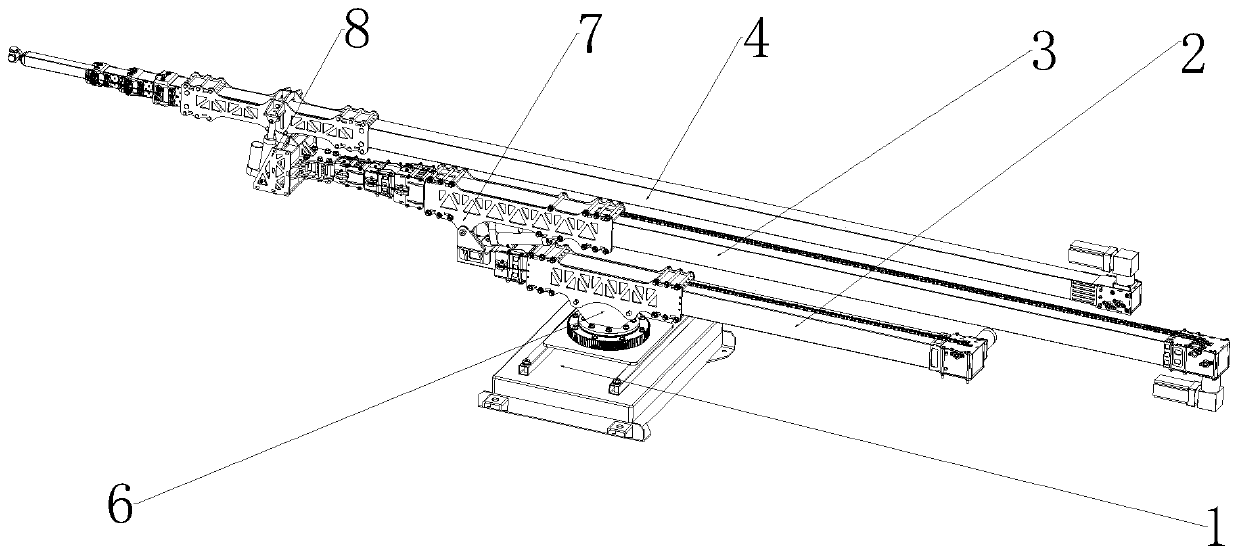

[0036] figure 1 An unexpanded perspective view of an embodiment of the present invention that does not include the detection device on which the vehicle is installed. An all-round small bridge detection machine mainly includes a detection device installation vehicle 5 , a scissor lift table 1 , a base telescopic arm 2 , a longitudinal telescopic arm 3 and a transverse detection arm 4 .

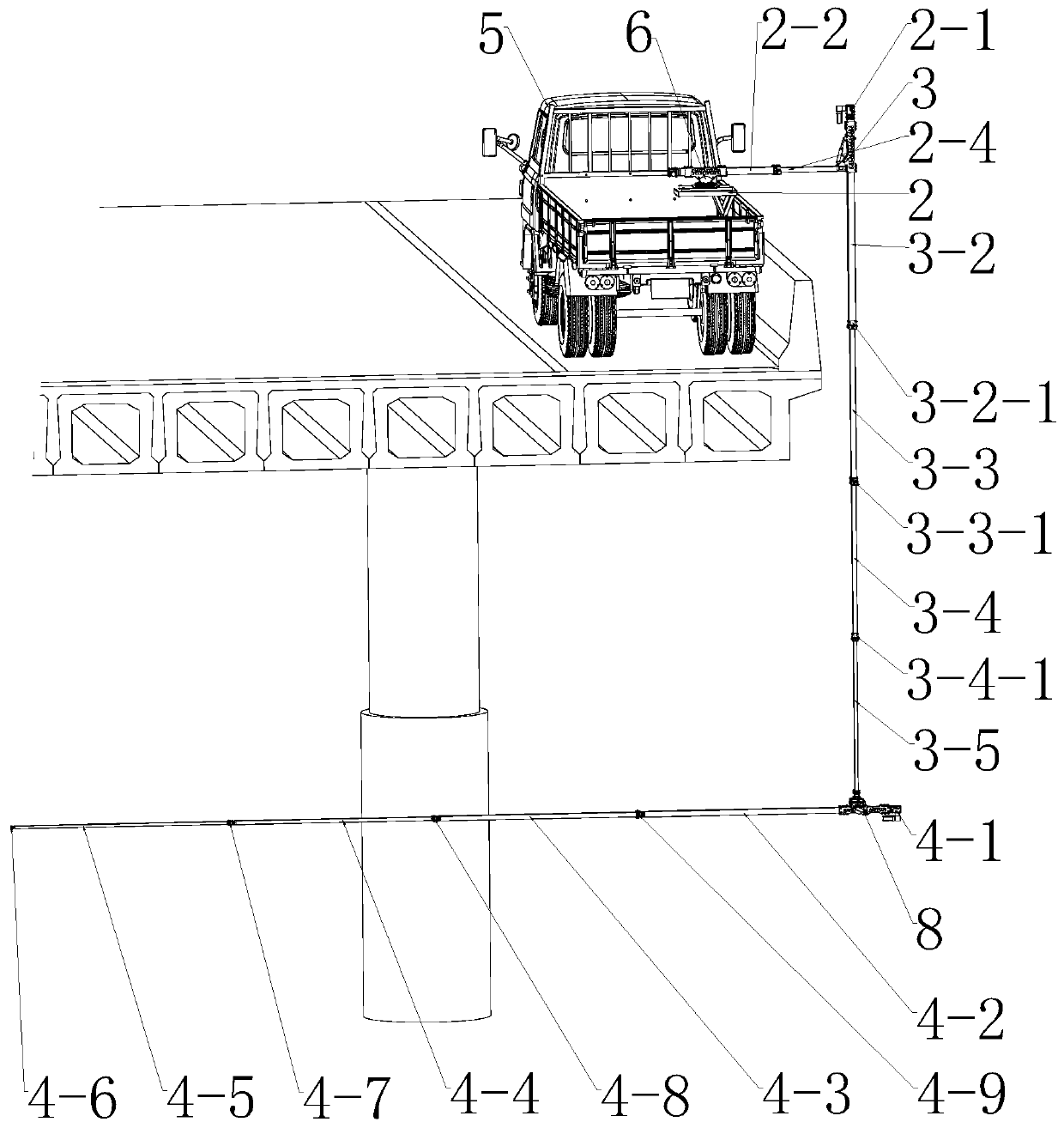

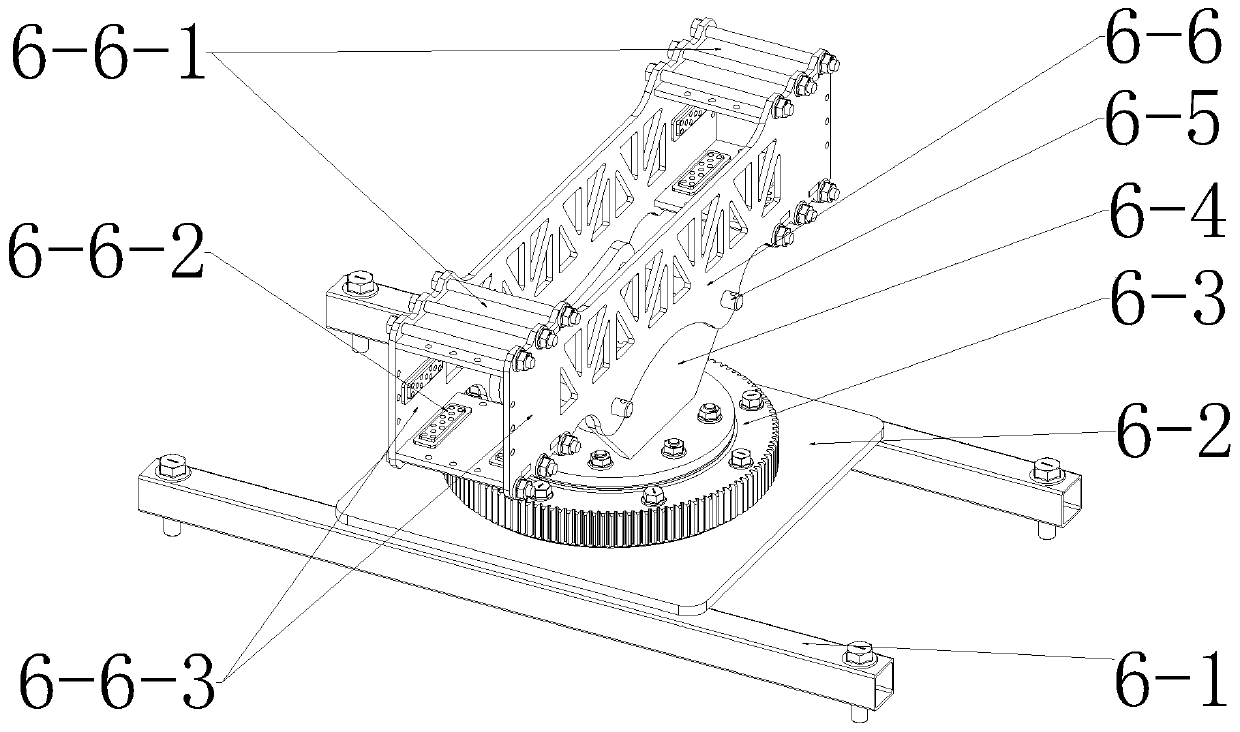

[0037] figure 2 It is a perspective view of the detection device of the present invention fully unfolded when it is working. The scissor lift table 1 is fixedly installed on the carriage floor of the detection device installation vehicle 5, and the base rotary assembly 6 is fixedly installed on the table surface of the scissor lift table 1; the base telescopic arm 2 connects with the scissor lift table through the base rotary assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com