Automatic rotating-disc type packaging and forming apparatus for lithium battery

A molding equipment, fully automatic technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult vacuum cycle, fast fixture wear, slow efficiency, etc., to reduce the need for operators, The effect of reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

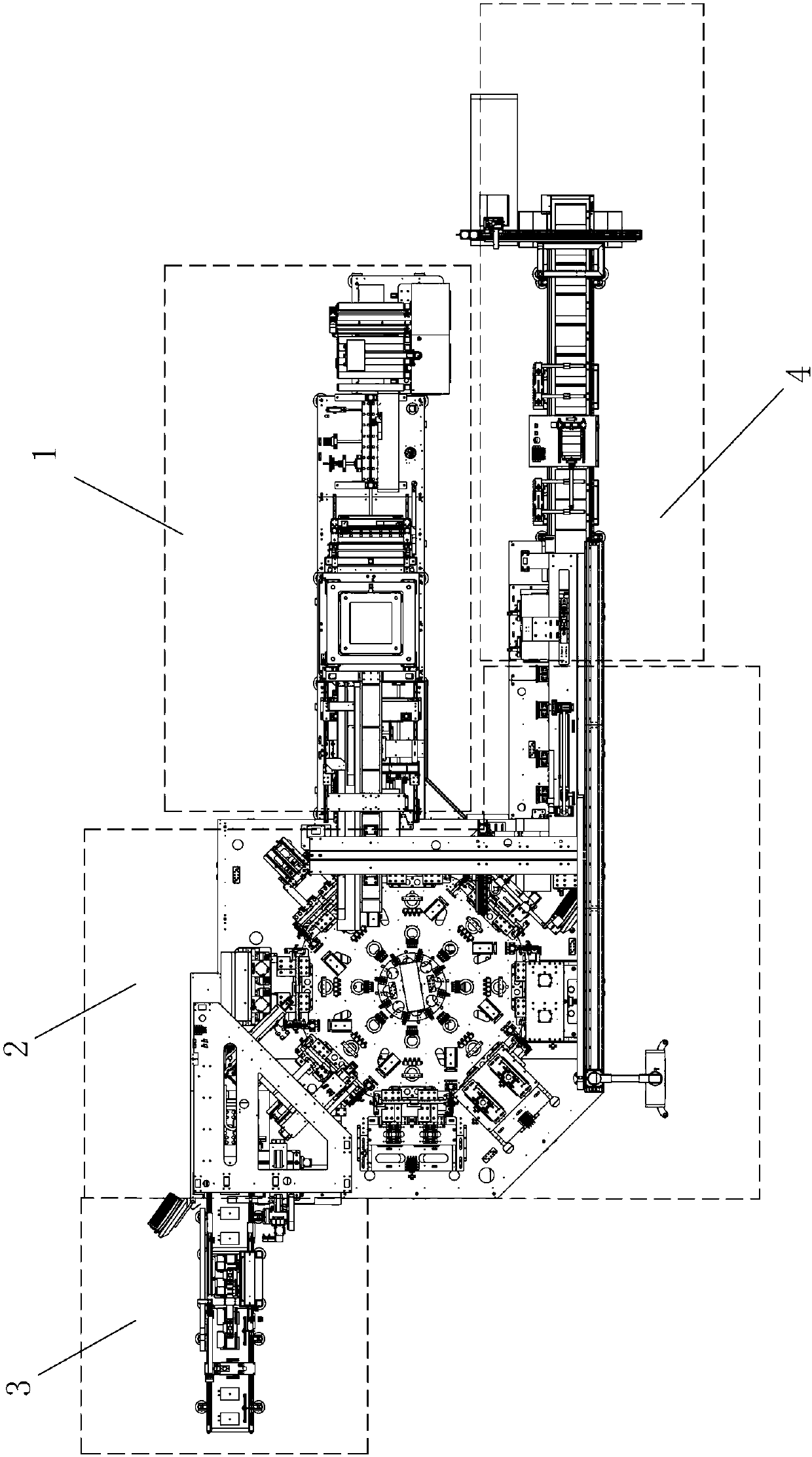

[0040] refer to figure 1 The structural block diagram of the lithium battery automatic turntable packaging and forming equipment shown.

[0041] The lithium battery automatic turntable packaging and forming equipment includes an aluminum-plastic film forming unit 1 , a cell packaging unit 2 , a feeding unit 3 and a discharging unit 4 .

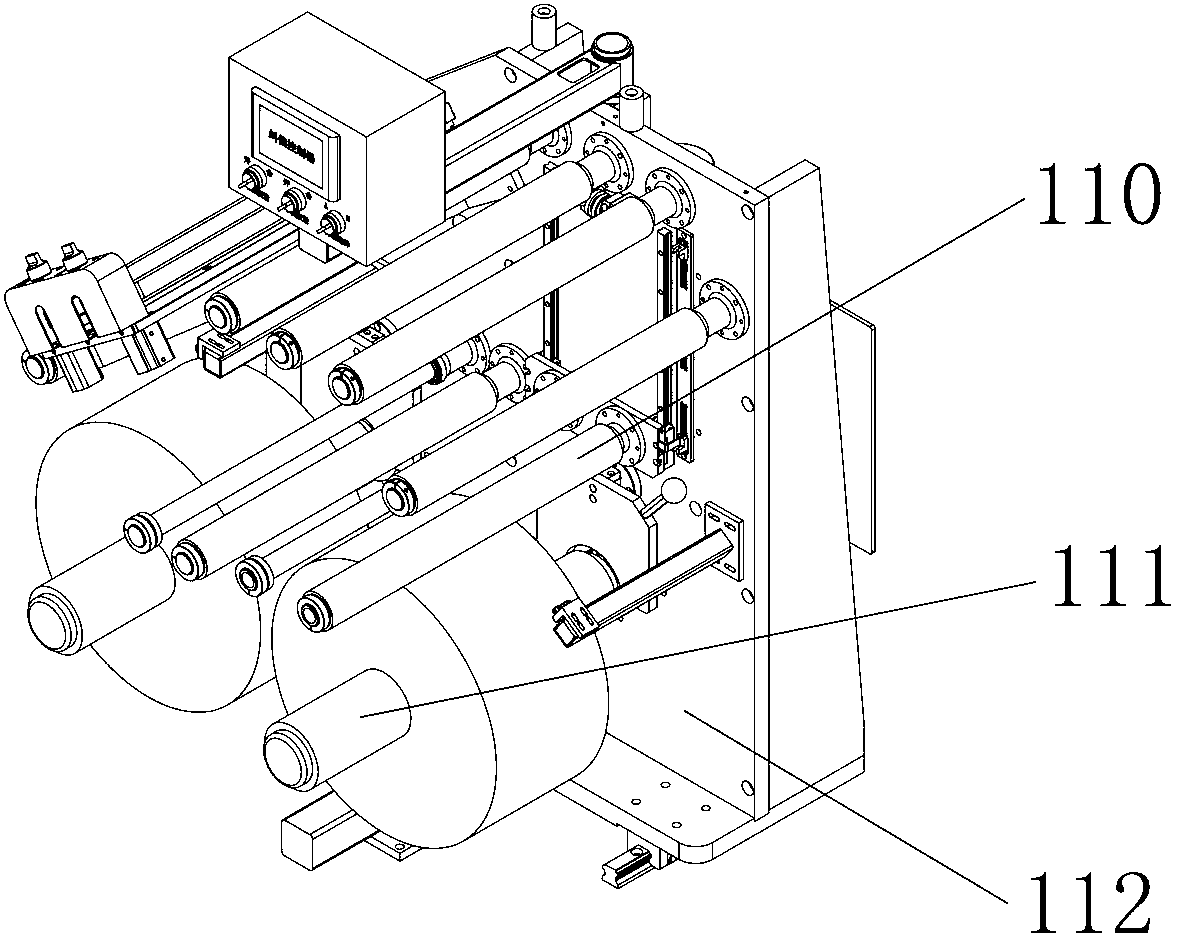

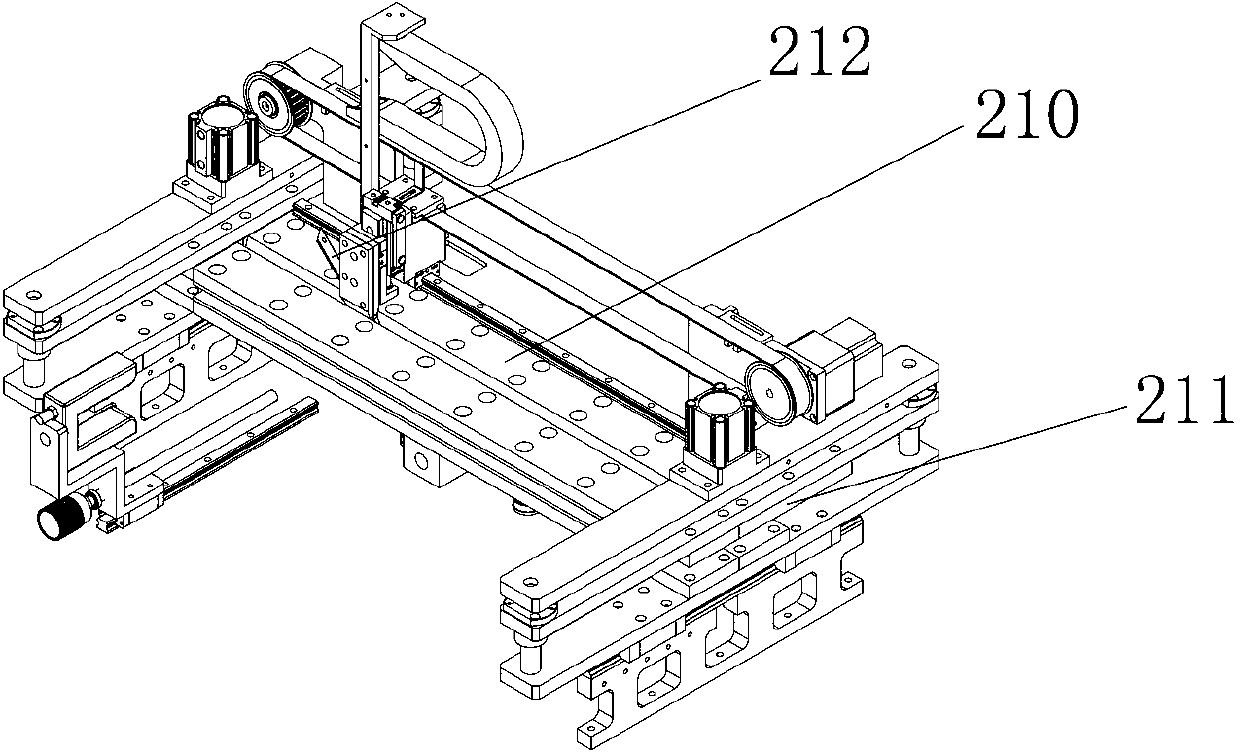

[0042] The aluminum-plastic film forming unit 1 includes an aluminum-plastic film unwinding mechanism arranged in sequence, a notch mechanism for cutting the aluminum-plastic film, a shell punching mechanism for punching a molding shell, and a cutting mechanism for cutting the aluminum-plastic film. The shell transfer mechanism that transfers the cut aluminum-plastic film to the battery packaging unit 2, the material receiving mechanism that catches the shell forward, the pulling mechanism that pulls the shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com