Drawing and bending molding process and die of refrigerator backboard

A technology of bending forming and drawing dies, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high production cost and low product quality, eliminate product distortion, reduce product forming processes, and save production The effect of device resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

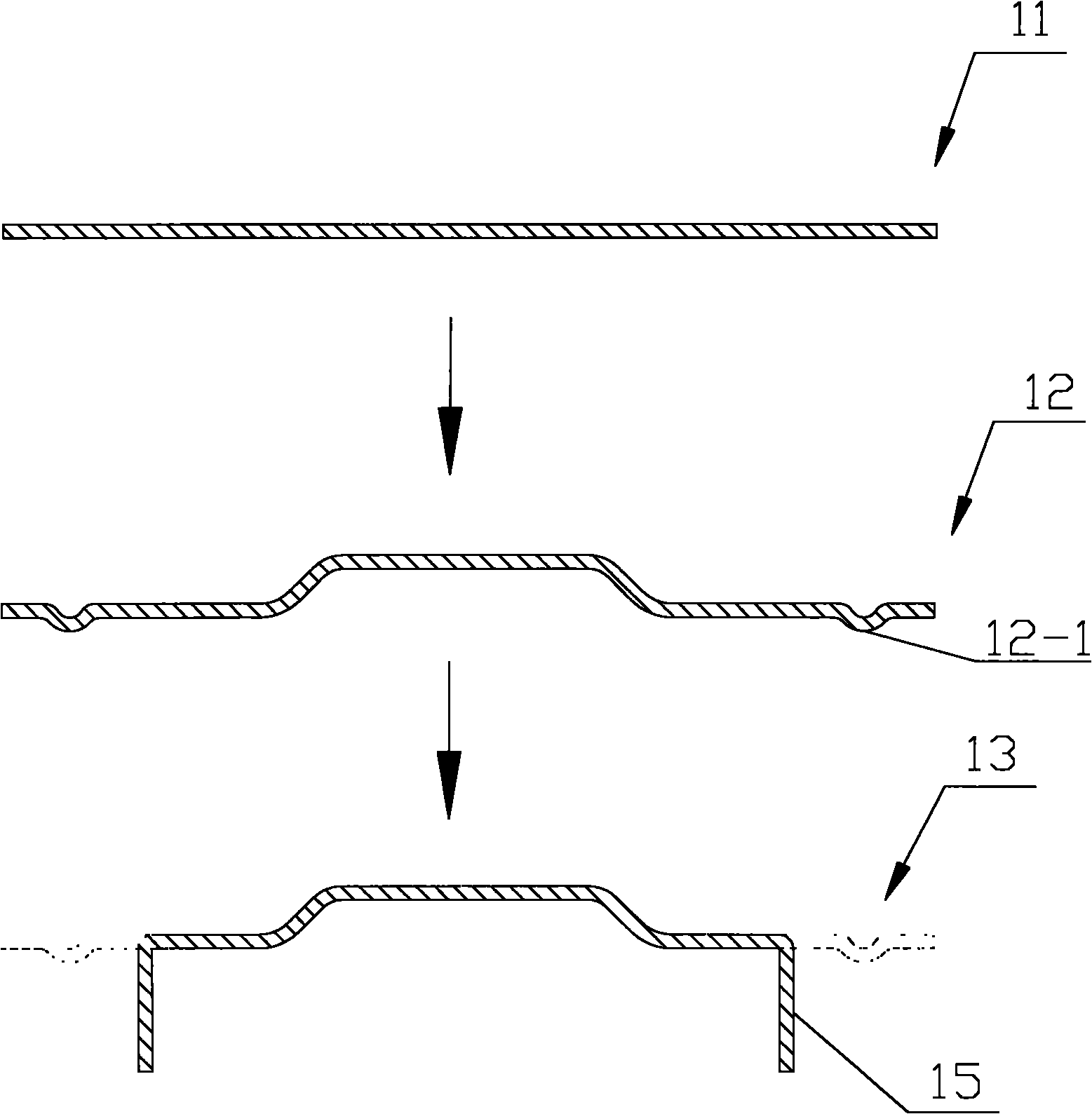

[0030] Such as figure 1 with Figure 4 As shown, a drawing and bending forming process of a sheet metal blank of a refrigerator back steel plate comprises the following steps:

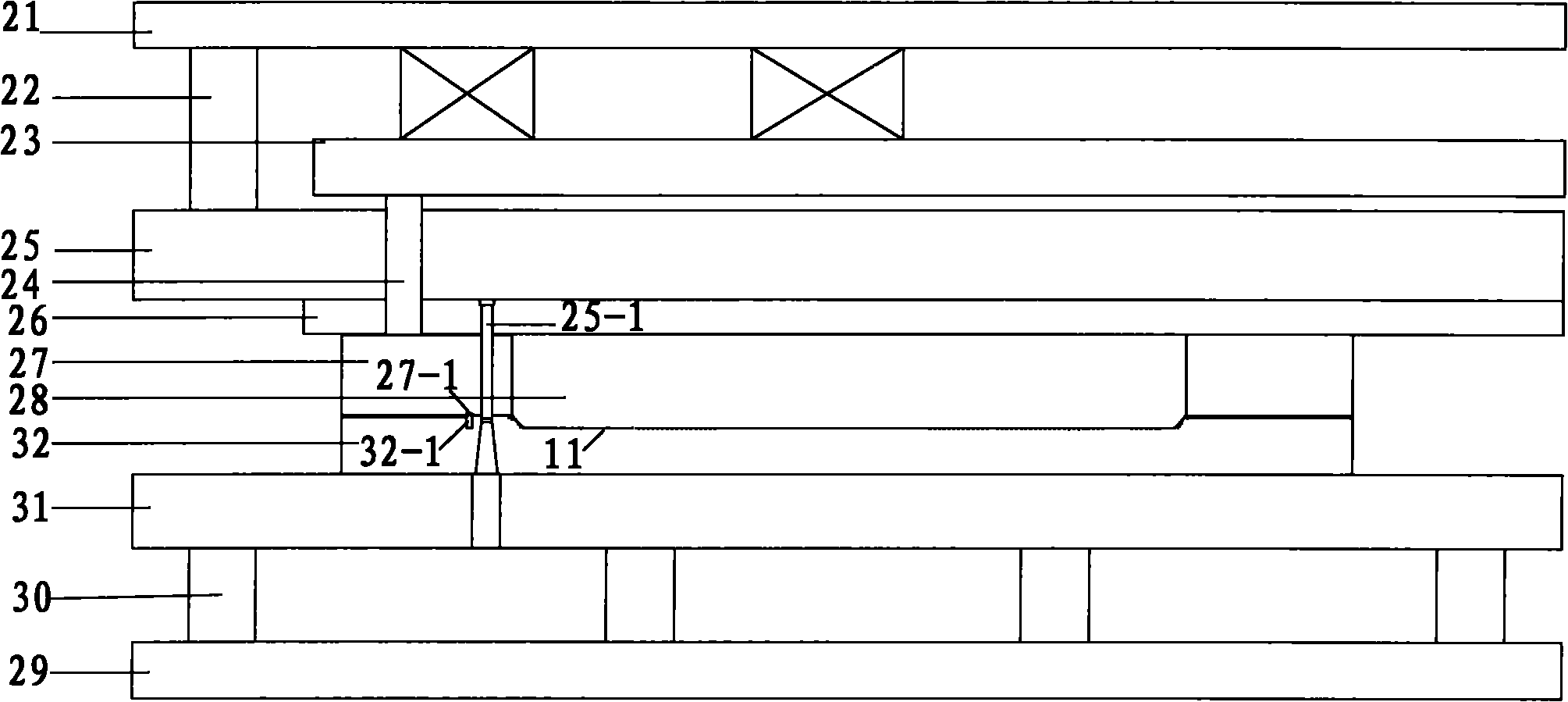

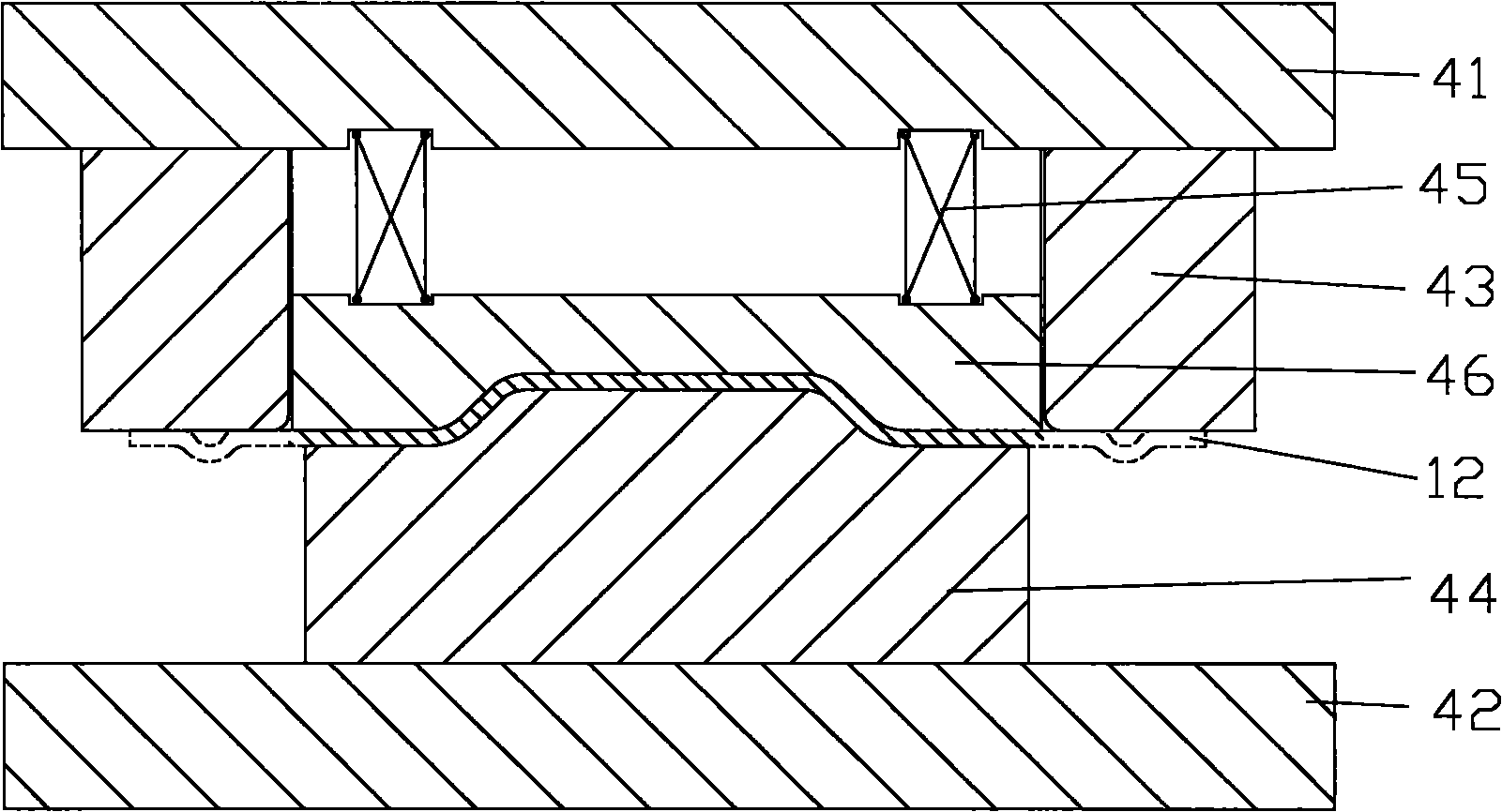

[0031] a, drawing: take rectangular sheet metal blank 11, adopt drawing die 20, such as figure 2 As shown, the drawing die includes an upper mold part and a lower mold part, and the upper mold part is an upper supporting plate 21, an upper foot 22, an upper cover plate 23 from top to bottom, and the upper cover plate 23 is connected with a push rod below 24, the upper die base 25 is connected below the upper pad foot 22, the upper backing plate 26 is connected under the upper die base 25, the upper stripping plate 27 and the punch 28 are connected under the upper backing plate 26, and the four corners of the upper die base 25 are provided with Punch 25-1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com