Pipe fittings notching-machine

A technology of groove pressing machine and pipe fittings, applied in the field of pipe fitting pressing groove machine, can solve the problems of inconvenient operation, complex structure, narrow pipe diameter range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

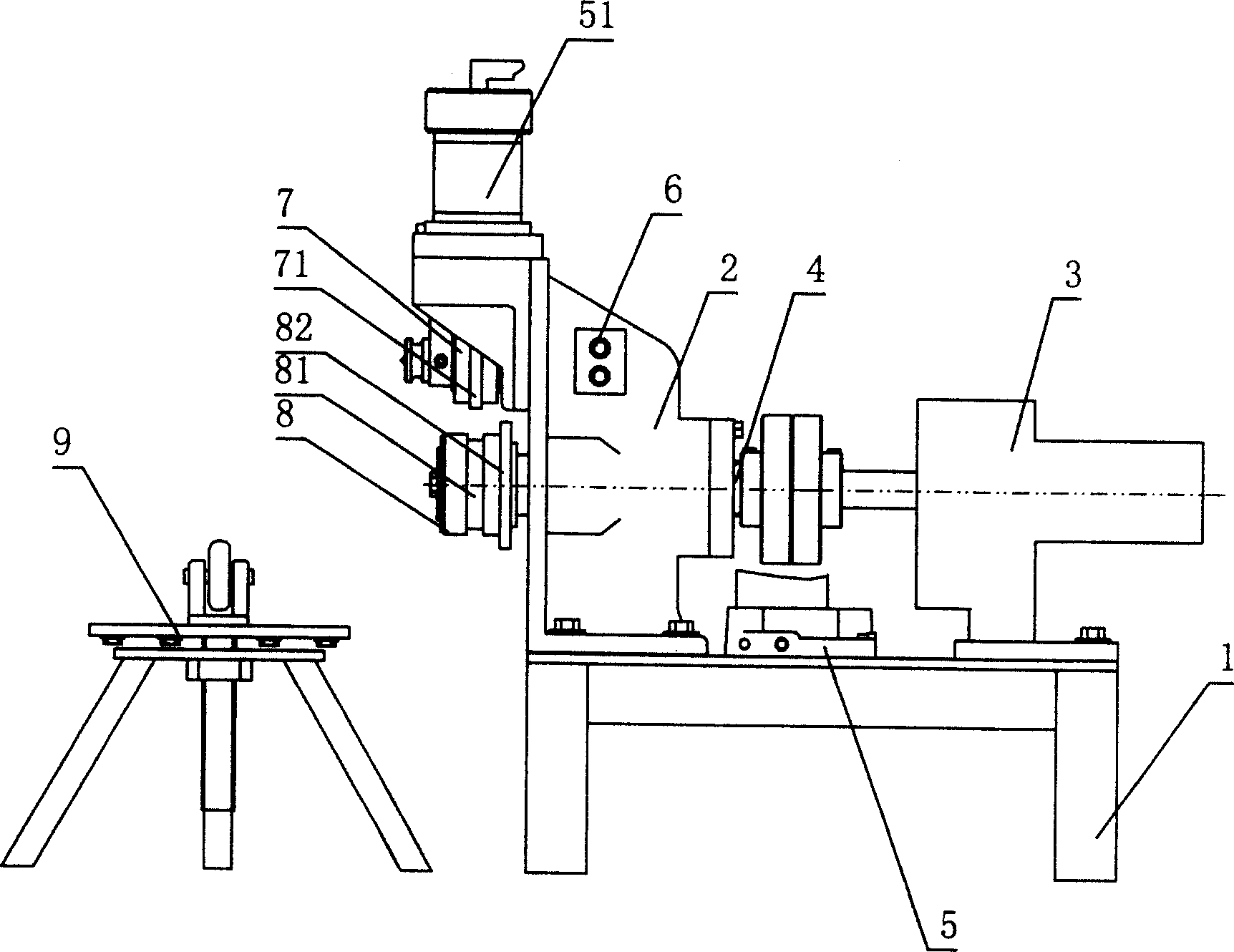

[0011] With reference to the accompanying drawings, a pipe fitting grooving machine of the present invention includes a base 1, a frame 2 arranged on the base 1, a main shaft 4 and a grooving wheel 7 are rotatably arranged on the frame 2, and the grooving wheel 7 is provided with a radial annular protrusion 71, one end of the main shaft 4 is connected to the output end of the deceleration drive device 3 that can drive the main shaft 4 to rotate at a low speed, and the other end of the main shaft 4 is detachably fixed with a supporting wheel 8. The wheel 8 is provided with a radial annular groove 81, and the grooving machine is also provided with a propelling device that can push the grooving wheel 7 to move. The propelling device can adopt a pressure pump 5 and a piston type as shown in the accompanying drawings The hydraulic propulsion device composed of the oil cylinder 51 drives the movement of the groove wheel 7 through the piston cylinder 51, which improves the stability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com