Color mark shearing method implemented by transverse cutting machine

A technology of cross-cutting machine and color code, applied in metal processing and other directions, can solve the problems of production waste, the controller cannot make correct adjustments, and affect the production continuity, and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

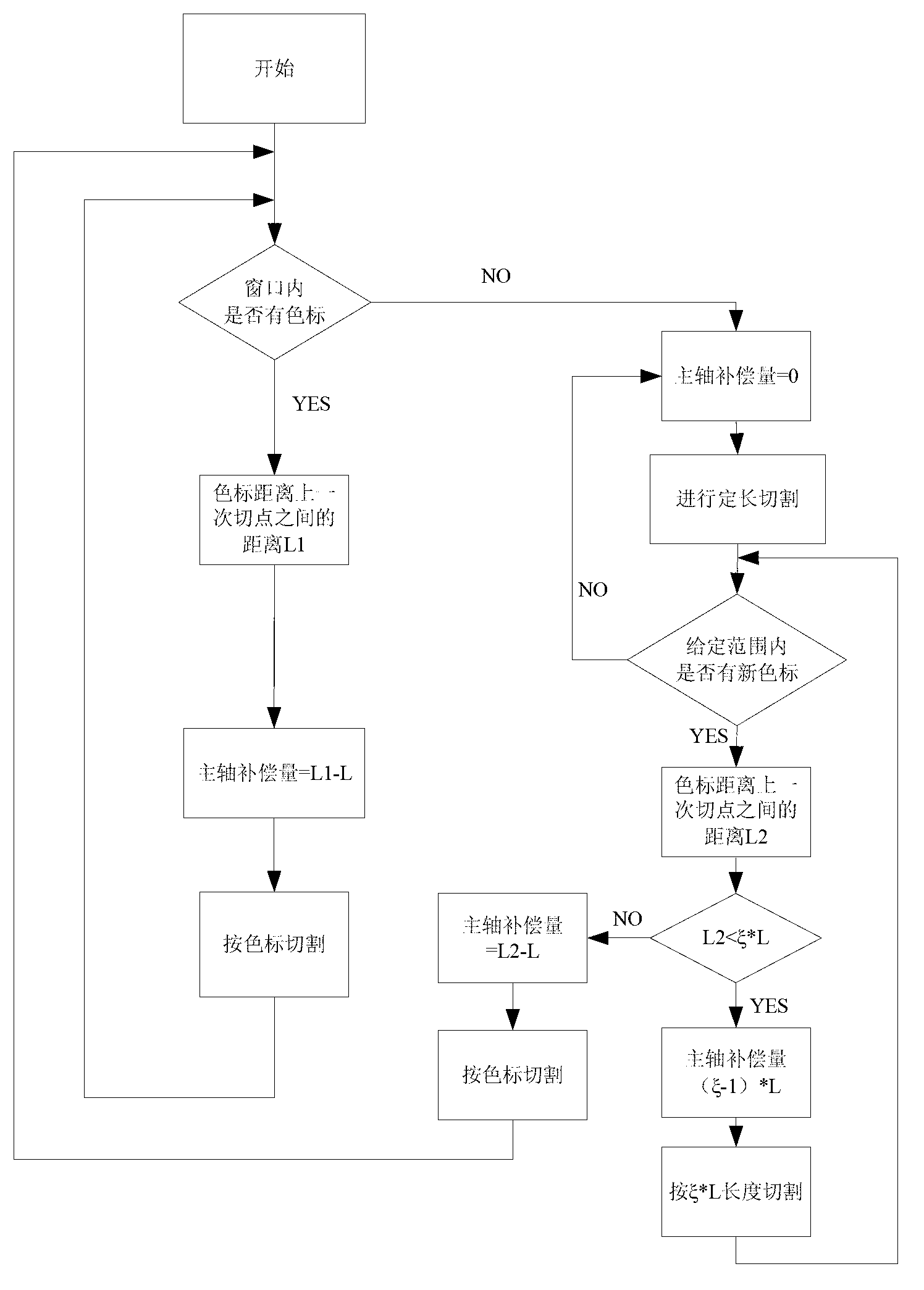

[0024] The invention aims at increasing the function of color code cutting on the basis of the original cross-cutting machine, and proposes a solution to the problem of missing marks during the color code cutting process.

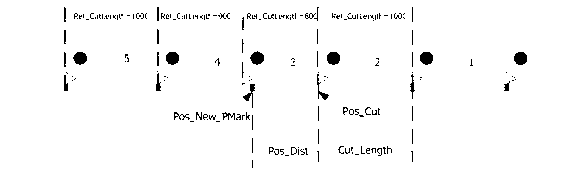

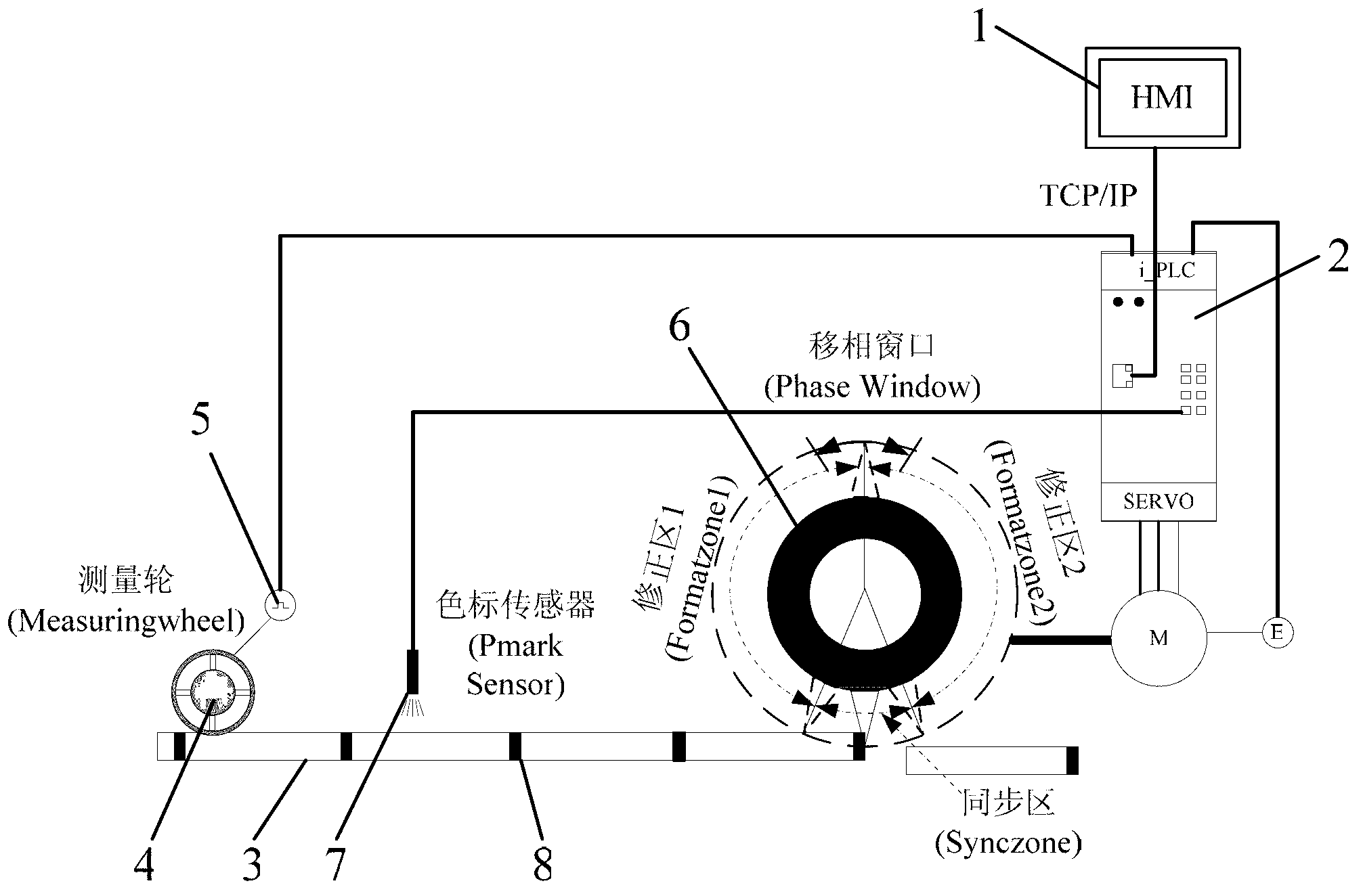

[0025] like figure 1 As shown, it is a cross-cutting machine system with color code cutting function. When working, employees input parameters such as mechanical size and actual given cutting length L from man-machine interface 1. When servo controller 2 receives these parameters , planning the cutting electronic cam curve table inside it. When the cardboard 3 starts to be tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com