Method and apparatus for detecting product defects during the production of mailing products, hygiene products, or folded paper products

a technology products, applied in the field of methods and apparatus for detecting product defects during the production of mailing products, hygiene products, or folded paper products, can solve the problems of essentially impossible to notice or detect defective products, waste of products, and other considerable damages and losses, and the sudden occurrence of errors or defects in products being produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

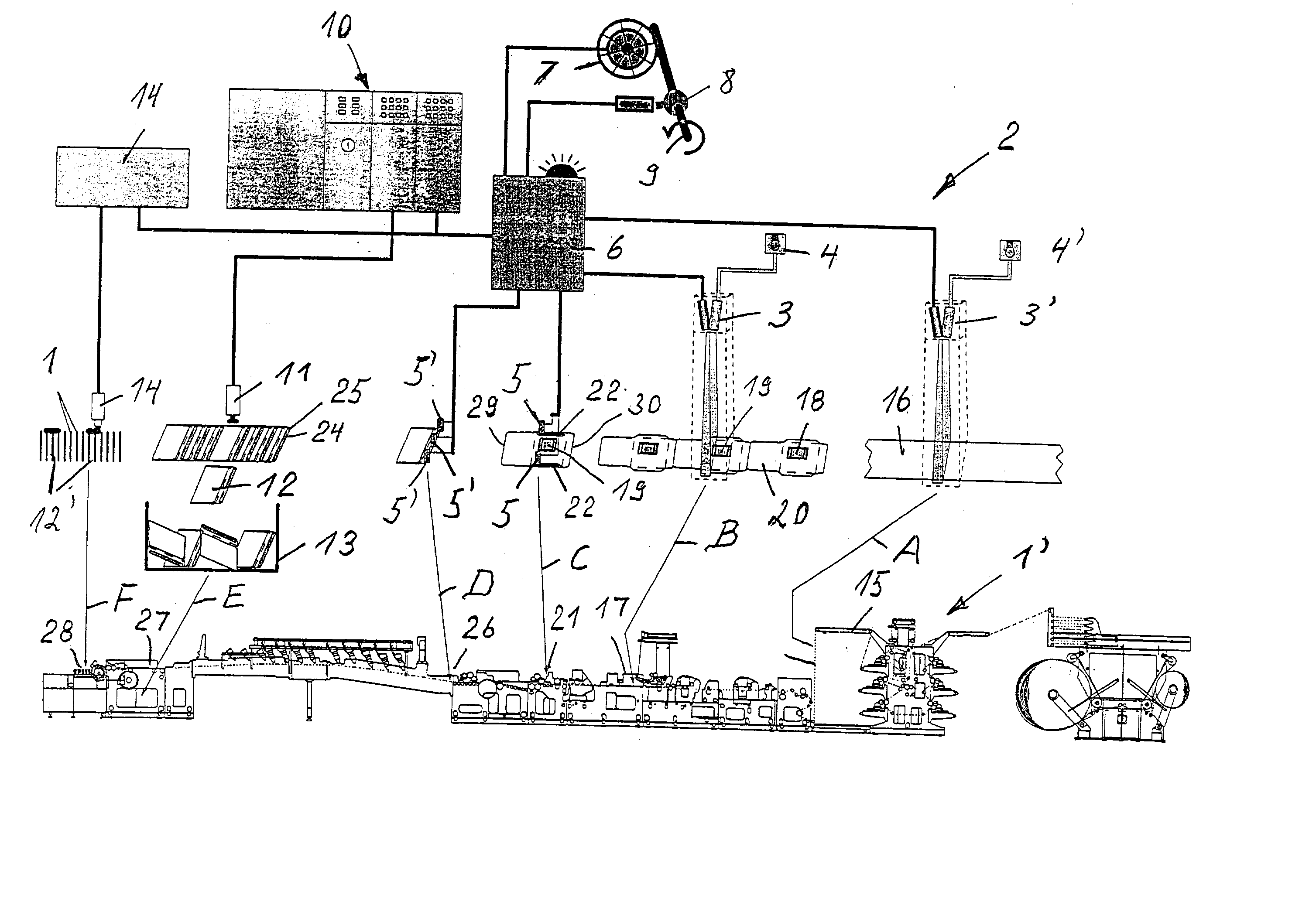

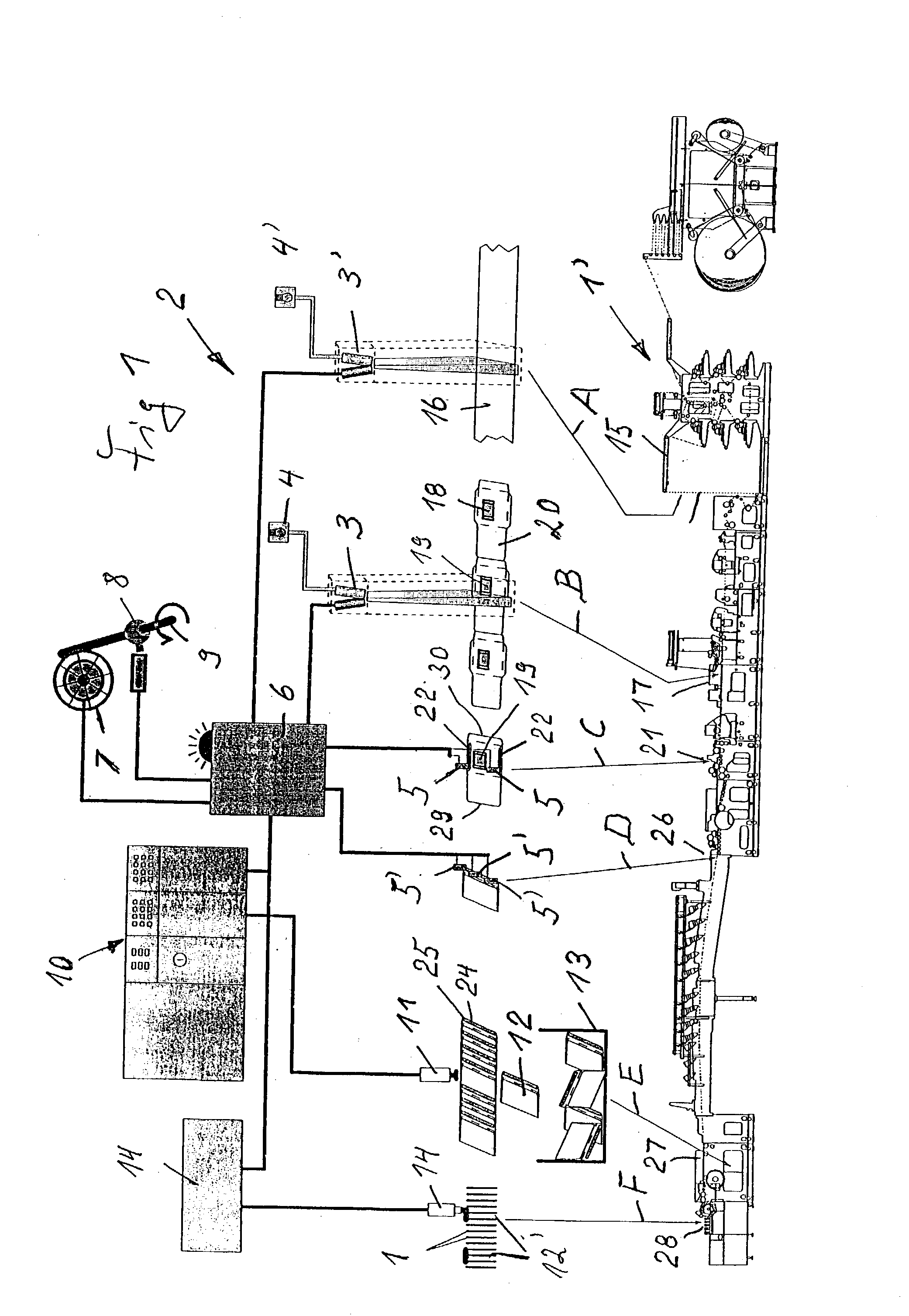

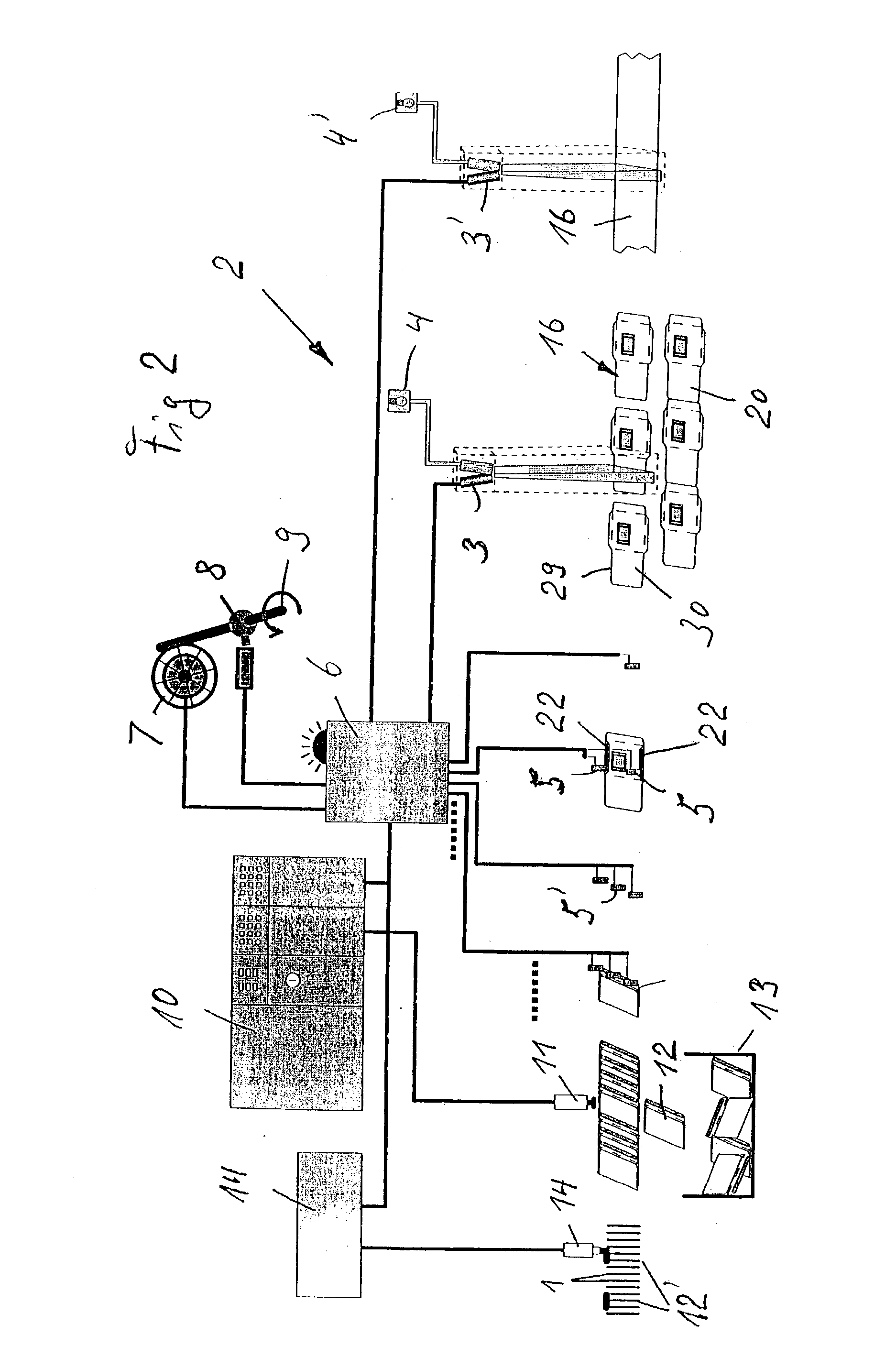

[0018] An apparatus 2 according to FIGS. 1 and 2 is provided for monitoring the production of letter envelopes 1 and the like by means of production machines 1'. The apparatus 2 comprises one or more sensors in the form of line cameras 3, 3', respectively with an associated light source 4, 4', and / or capacitively functioning sensors 5, 5'. For example, imaging sensors are provided for monitoring and inspecting the glue that has been provided as a strip, line or track along the side flaps of the envelopes 1, while capacitive sensors are predominantly provided for inspection and monitoring of the glue provided as a strip or track along the closure flaps of the envelopes 1.

[0019] The line cameras 3, 3' and the capacitive sensors 5, 5' respectively provide signals to an evaluating electronics 6, e.g. an evaluating electronic circuit 6. A rotation transmitter or pickup 7, to which a measuring wheel can be allocated, is further connected to the evaluating electronics 6, and basically the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| defects | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com