High-strength corrugated-paper production process

A production process and technology of corrugated paper, applied in the field of corrugated paper, can solve the problems of low product quality and strength, short service life and high production cost, and achieve the effects of low production cost, long service life and low consumption of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

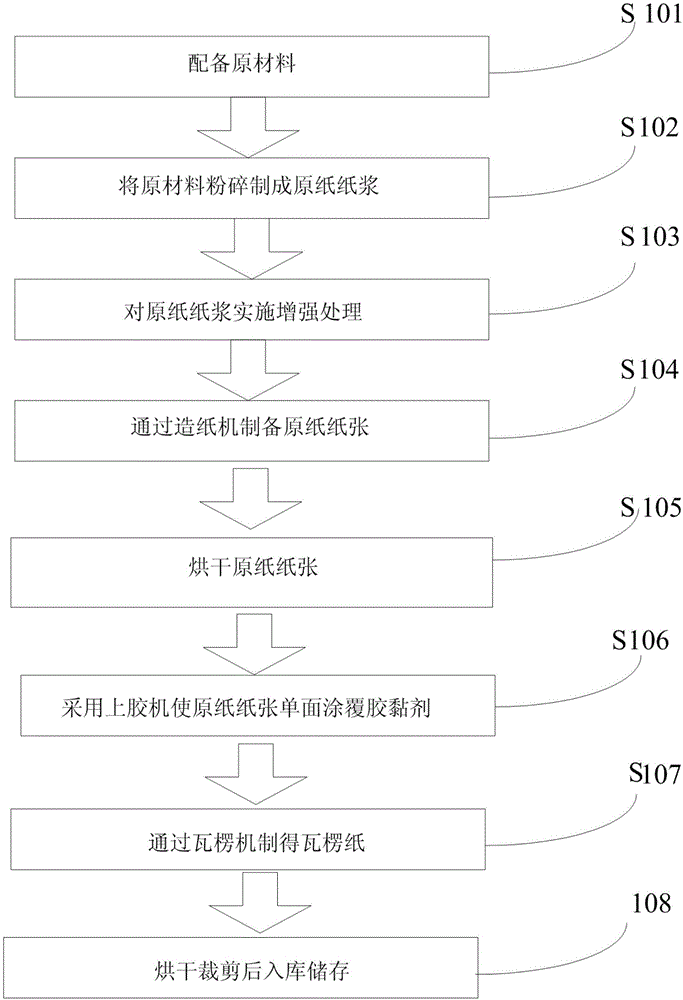

[0028] as attached figure 1 shown

[0029] A high-strength corrugated paper production process includes the following steps:

[0030] S101: equipped with raw materials;

[0031] S102: crushing raw materials to make base paper pulp;

[0032] S103: performing enhanced treatment on the raw paper pulp;

[0033] S104: Preparing base paper by a paper machine;

[0034] S105: drying the base paper;

[0035] S106: Coating adhesive on one side of the base paper with a glue machine;

[0036] S107: producing corrugated paper through a corrugating machine;

[0037] S108: After drying and cutting, store in storage.

[0038] Further, in S101, the raw materials are crop stalks and waste paper, soaked with water, put into a pulper and pulverized, so that the raw materials are dissociated into fibers, and filtered and screened to remove crude fibers and impurities, and the fiber length is 1.0 ~2.0mm.

[0039] Further, in S102, the base paper pulp preparation temperature is 40°C-50°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com