High-safety assembling tool based on torque feedback

An assembly tooling and high-safety technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, high labor intensity, and low degree of automation, so as to improve product quality and reduce labor intensity , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

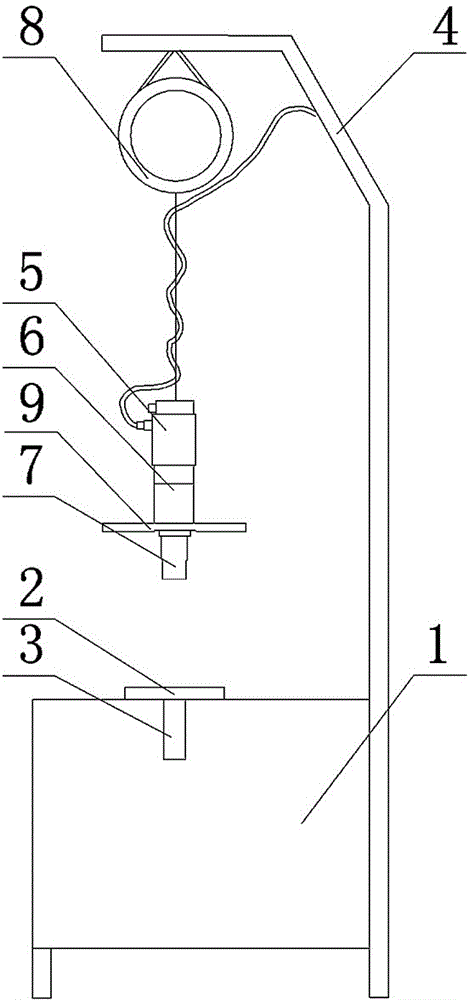

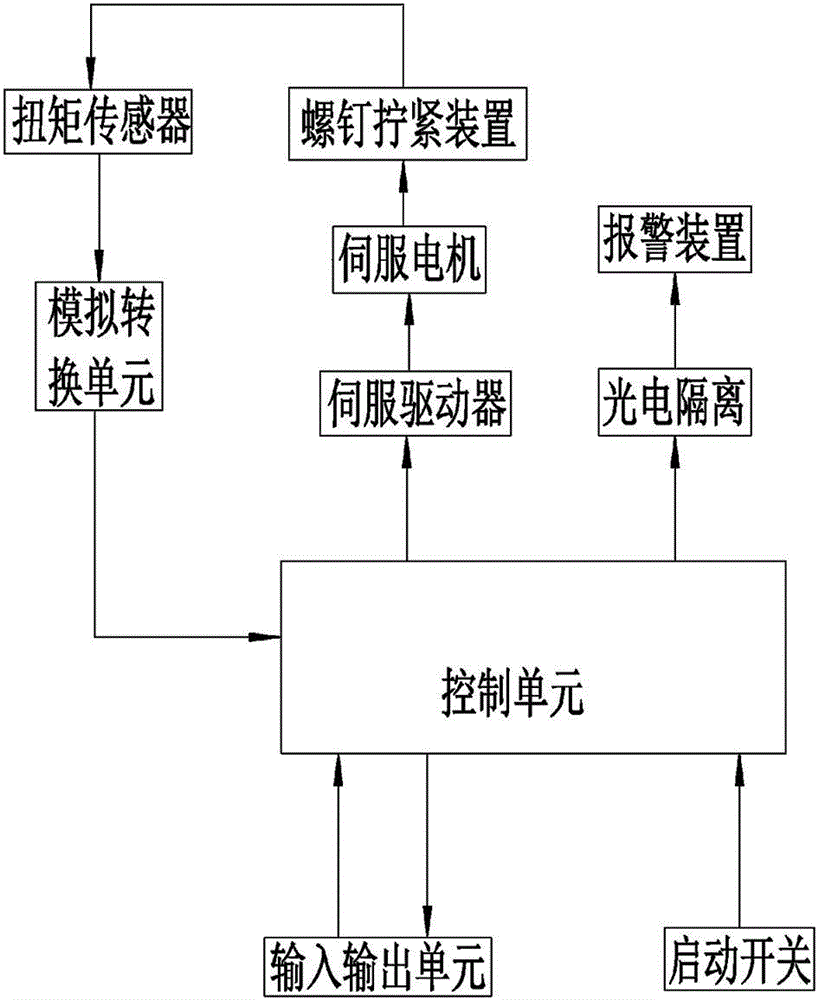

[0018] Such as figure 1 As shown, a high-safety assembly tool based on torque feedback includes a workbench 1, a screw tightening device and a controller. The upper surface of the workbench 1 is provided with a product fixture 2, and the product fixture 2 is connected to a torque sensor 3. The working A crossbeam 4 is arranged on the top of the table 1, and the crossbeam 4 is fixed on the workbench 1 through a pole, and the screw tightening device is arranged on the crossbeam 4, and the screw tightening device includes a servo motor 5, a reducer 6 and a screw sleeve 7, The servo motor 5 is connected with the reducer 6 through a key, the output shaft of the reducer 6 is connected with the coupling, and the coupling is connected with the replaceable screw sleeve 7, the beam 4 is provided with a spring balancer 8, and the servo motor 5 is connected At the lower end of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com