Method for optimizing electromagnetic performance of non-oriented silicon steel, and non-oriented silicon steel

An oriented silicon steel, electromagnetic technology, applied in the field of steelmaking, can solve problems such as difficulty, inability to meet downstream enterprises, and low level, and achieve the effect of improving electromagnetic performance and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Smelting according to the set composition, the chemical composition contains: C 0.004%, Si 0.65%, Mn0.22%, P 0.035%, Als 0.28%, S 0.003%, O 0.002%, N 0.0025%, Nb≦0.004, V≦0.004, Ti≦0.004, Cr≦0.005, and the rest are Fe and unavoidable impurities; the slab is made by continuous casting with a continuous casting machine, and the thickness of the slab is 72mm;

[0017] 2) Billets are heated in a roller-type heating furnace with a heating temperature of 1050°C; the starting rolling temperature is 1046°C; the finishing rolling temperature is 865°C; rolling plate;

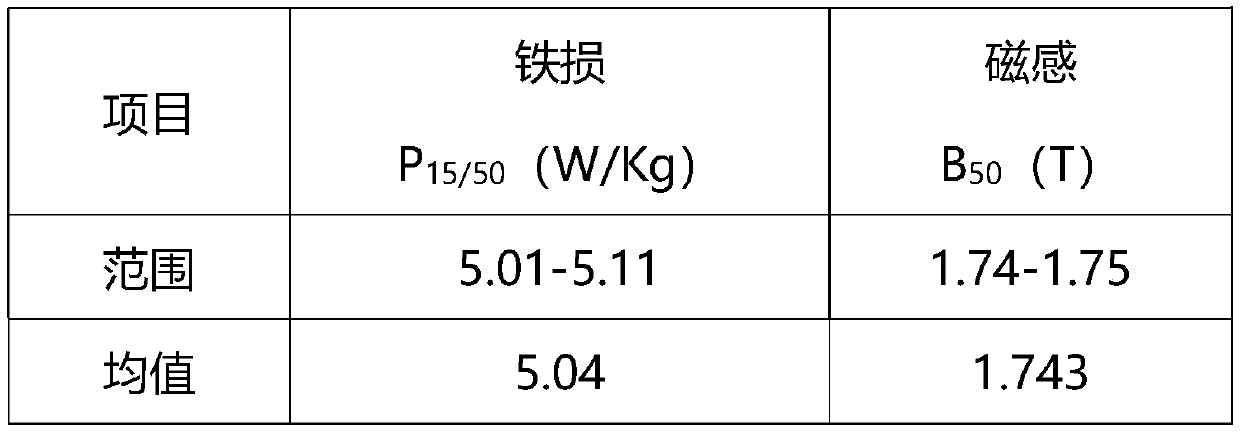

[0018] 3) Hot-rolled coils are pickled by pickling unit, rolled to 0.5mm in 5 passes of CVC6-roll single-stand cold rolling mill; continuous annealing, NOF section: 1000-1050℃, RTF section: 890℃, SF section: 890 -930°C, the annealing time is 3min, and finally coated with an insulating film to make a non-oriented silicon steel coil. Its iron loss (P15 / 50) is 5.01w / kg, and its magnetic induction (B50) is 1.74T. ...

Embodiment 2

[0020] 1) Smelting according to the set composition, the chemical composition of molten steel contains: C 0.0035%, Si0.71%, Mn 0.25%, P 0.030%, Als 0.27%, S 0.0035%, O 0.0022%, N 0.0028% , Nb≦0.004, V≦0.004, Ti≦0.004, Cr≦0.005, the rest is Fe and unavoidable impurities; the thickness of continuous casting slab is 70mm;

[0021] 2) The billet is heated and overheated, the heating temperature is 1065°C; the starting rolling temperature is 1055°C; the final rolling temperature is 868°C; the coiling temperature is 696°C, and the thickness of the hot-rolled coil is 2.75mm;

[0022] 3 Continuous annealing temperature, NOF section: 1000-1040°C, RTF section: 900°C, SF section: 880-920°C, annealing time is 2.5min, and finally coated with insulating film to make non-oriented silicon steel coil. After testing, the iron loss (P15 / 50) is 5.11w / kg, and the magnetic induction (B50) is 1.75T.

Embodiment 3

[0024] 1) Smelting according to the set composition, the chemical composition of molten steel contains: C 0.0032%, Si0.73%, Mn 0.27%, P 0.031%, Als 0.30%, S 0.0032%, O 0.0023%, N 0.0030% , Nb≦0.004, V≦0.004, Ti≦0.004, Cr≦0.005, the rest is Fe and unavoidable impurities; the thickness of continuous casting slab is 70mm;

[0025] 2) Slab heating and overheating, heating temperature 1075°C; starting rolling temperature 1060°C; finishing rolling temperature 872°C; coiling temperature 708°C;

[0026] 3) Continuous annealing temperature, NOF section: 1020-1050°C, RTF section: 900°C, SF section: 900-930°C, annealing time is 3.5min, and finally coated with insulating film to make non-oriented silicon steel coil. Its iron loss (P15 / 50) is 5.08w / kg, and its magnetic induction (B50) is 1.74T.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com