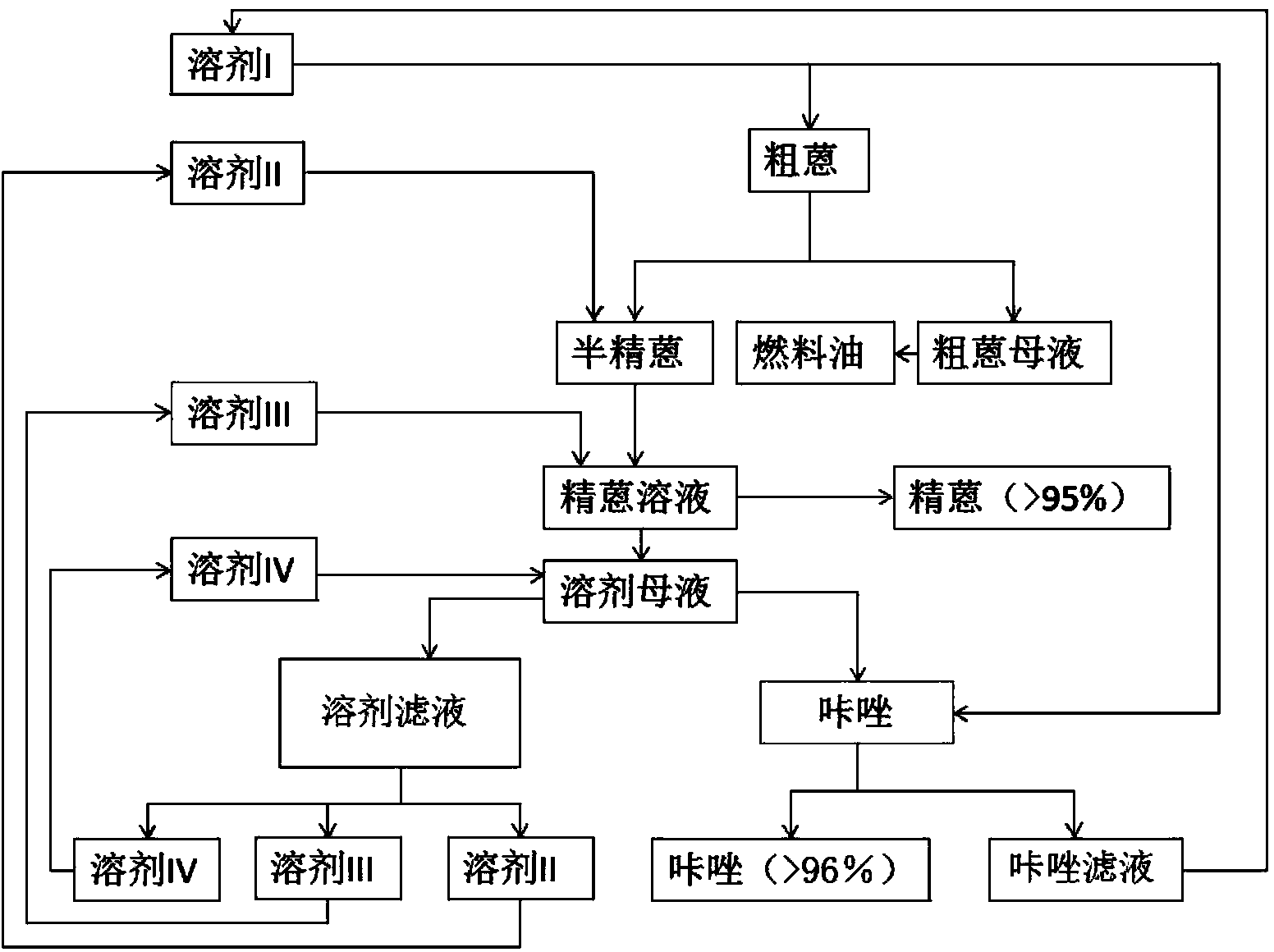

Refined anthracene and carbazole purification method

A purification method and carbazole technology are applied in the field of continuous, rapid and efficient purification of refined anthracene and carbazole, which can solve the problems of large solvent consumption, low product yield and product quality, and increased extraction times, etc. The effect of few operation steps and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The purification method of refined anthracene and carbazole provided in this embodiment, the steps are:

[0046]Step 1. Add 75kg of crude anthracene raw material into xylene, wherein the quality of xylene is 150kg, heat to 80°C to completely dissolve, cool down, let the solvent mother liquor stand at 20°C until complete crystallization, filter, and vacuum-dry the filter cake, Obtain 31kg of semi-refined anthracene and crude anthracene mother liquor, the crude anthracene mother liquor can replace xylene to dissolve subsequent crude anthracene raw materials, again make new semi-refined anthracene and crude anthracene mother liquor under the conditions of step 1, and repeat the above process for the crude anthracene mother liquor until the crude anthracene mother liquor The anthracene mother liquor is saturated, and the saturated crude anthracene mother liquor can be used as fuel oil.

[0047] Step 2, add 31kg of semi-refined anthracene in step 1 to DMF, wherein the qualit...

Embodiment 2

[0051] The purification method of refined anthracene and carbazole provided in this embodiment, the steps are:

[0052] Step 1. Add 750kg of crude anthracene raw material into xylene, wherein the quality of xylene is 1500kg, heat to 80°C to completely dissolve, cool, let the solvent mother liquor stand at 20°C until it is completely crystallized, filter, and dry the filter cake in vacuum. Obtain 307kg of semi-refined anthracene and crude anthracene mother liquor, the crude anthracene mother liquor can replace xylene to dissolve subsequent crude anthracene raw materials, again make new semi-refined anthracene and crude anthracene mother liquor under the conditions of step 1, the crude anthracene mother liquor repeats the above process until the crude anthracene mother liquor The anthracene mother liquor is saturated, and the saturated crude anthracene mother liquor can be used as fuel oil.

[0053] Step 2, add 307kg of semi-refined anthracene in step 1 to DMF, wherein the quali...

Embodiment 3

[0057] The purification method of refined anthracene and carbazole provided in this embodiment, the steps are:

[0058] Step 1. Add 750kg of crude anthracene raw material to toluene, wherein the mass of toluene is 1400kg, heat to 80°C to completely dissolve, cool, let the solvent mother liquor stand at 20°C until it is completely crystallized, filter, and dry the filter cake in vacuum to obtain 310kg Semi-refined anthracene and crude anthracene mother liquor, the crude anthracene mother liquor can replace toluene to dissolve subsequent crude anthracene raw materials, and then prepare new semi-refined anthracene and crude anthracene mother liquor under the conditions of step 1 again, and the crude anthracene mother liquor repeats the above process until the crude anthracene mother liquor is saturated , the saturated crude anthracene mother liquor can be used as fuel oil.

[0059] Step 2, add 310kg of semi-refined anthracene in step 1 to DMF, wherein the quality of DMF is 750kg,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com