Stepping motor comprehensive performance test system

A technology of comprehensive performance testing and stepping motor, applied in the testing field, can solve the problems of insufficient testing effect and insufficient testing efficiency, and achieve the effect of improving product quality level, low production cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

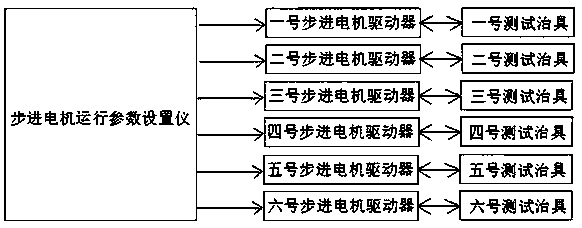

[0027] Such as figure 2 As shown, the stepper motor comprehensive performance test system consists of three parts: a stepper motor operating parameter setter, six stepper motor drivers of the same specification, and six sets of motor test fixtures of the same specification; the test system can simultaneously The steering, torque, angle, current, and insulation withstand voltage performance of the six stepping motors are tested. The connection method of the three components is: the stepper motor operation parameter setting instrument sends the relevant parameters to the stepper motor driver through the power line and the signal connection line; the stepper motor driver controls the stepper motor through the electrical connection line. At the same time, the cylinder of the motor test fixture is controlled to perform corresponding work, and the steering, torque, angle, current, and insulation withstand voltage performance of the motor are tested.

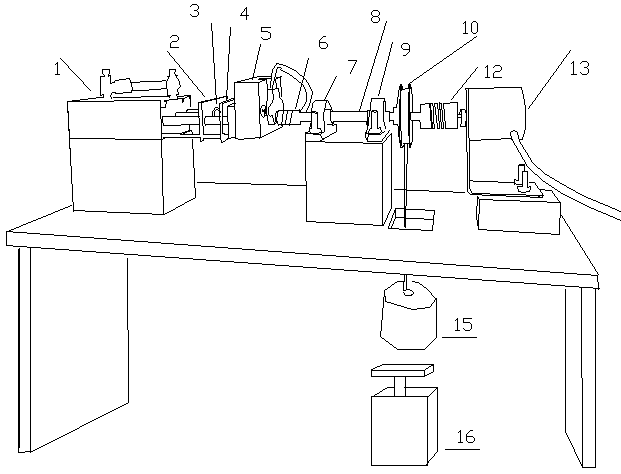

[0028] Each of the six sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com