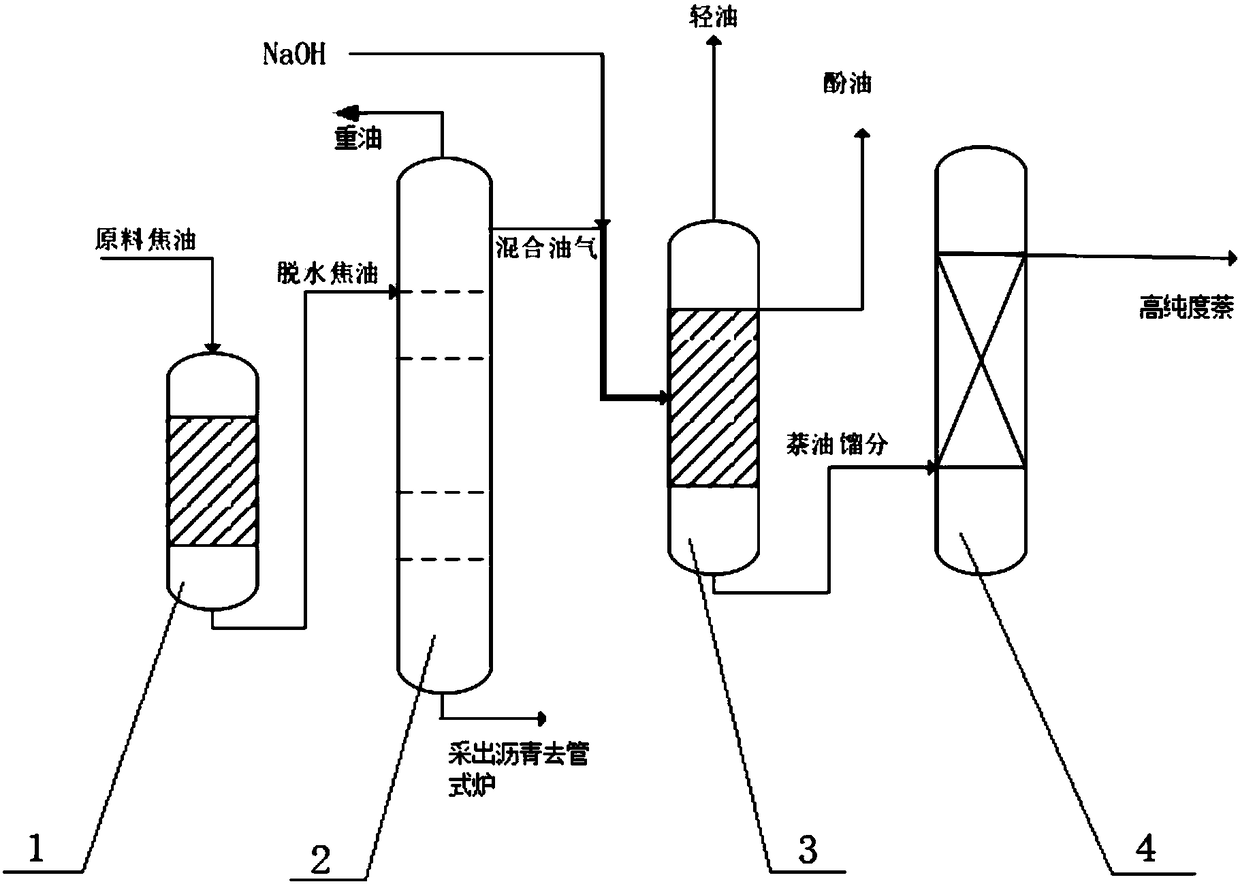

Coal tar deep processing technology for directly extracting industrial naphthalene by adding alkali after normal- and reduced-pressure treatments

A technology of atmospheric pressure and coal tar, applied in the field of coal chemical industry, can solve the problems of inconspicuous separation effect and difficult operation, and achieve the effects of avoiding small operating space, saving energy in the process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Coal tar deep processing technology that directly extracts industrial naphthalene by adding alkali after atmospheric and decompression. Coal tar is used as raw material, and alkali is directly added after atmospheric and decompression. The initial distillation tower and front tower are used for negative pressure operation, and other parts are operated under normal pressure. , the specific process is as follows:

[0040] 1) The crude tar from the tar storage tank is sent to the tar preheater to mix with light oil, the preheater preheats the crude tar from 60°C to 105°C, the mixture of crude tar and light oil enters from the upper part of the dehydration tower, In the dehydration tower, the azeotrope of water, benzene, toluene and xylene is extracted from the upper part; the dehydrated tar flows out from the lower part of the dehydration tower, and a small part of the outflow dehydrated tar passes through the reboiler, and the temperature rises from 178°C to 189°C. Provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com