Torque-fixed screw fastening apparatus for detecting screw slippage state

A technology of tightening screws and constant torque, applied in the direction of torque/torsional force measurement, sequence/logic controller program control, electrical program control and other directions during tightening, which can solve the problem of low production efficiency, high labor intensity and low degree of automation. and other problems to achieve the effect of improving product quality level, improving work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

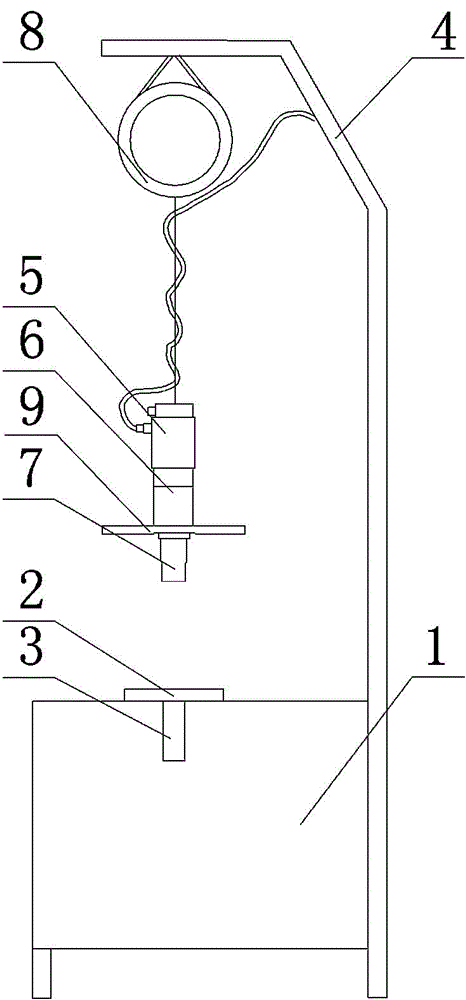

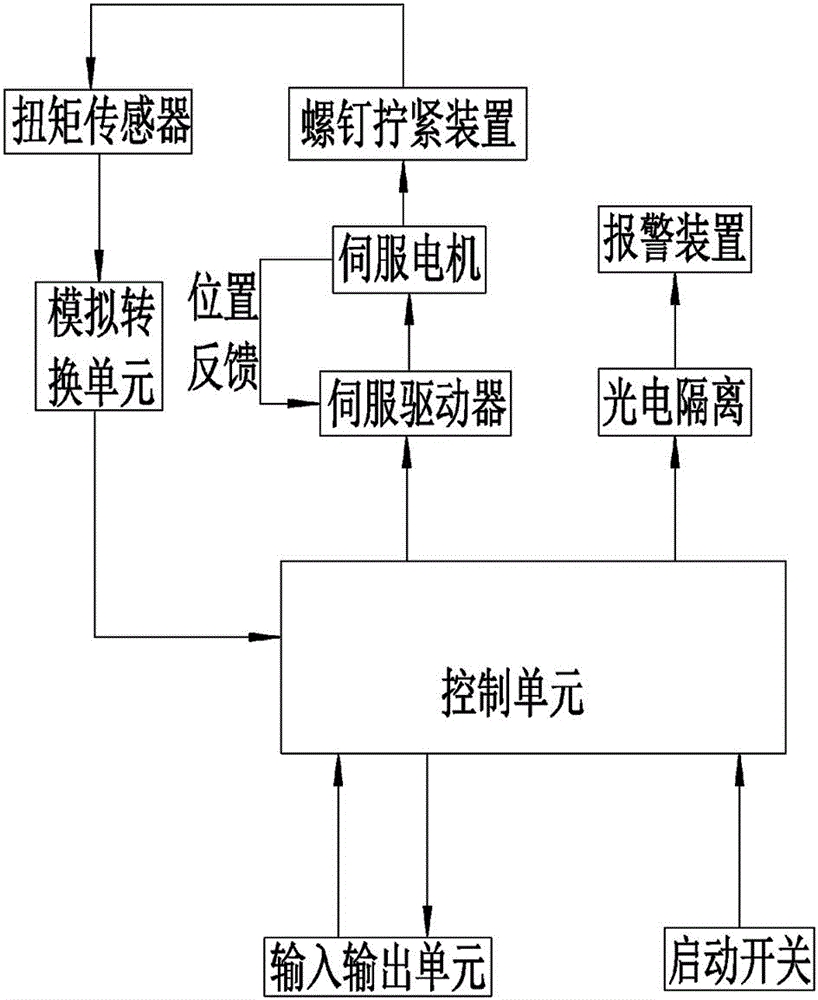

[0018] Such as figure 1 As shown, a device for fastening screws with a constant torque that can detect the state of the bolt sliding tooth, it includes a workbench 1, a screw tightening device and a controller, the upper surface of the workbench 1 is provided with a product fixture 2, and the product fixture 2 is connected with The torque sensor 3 is provided with a crossbeam 4 above the workbench 1, and the crossbeam 4 is fixed on the workbench 1 through a pole, and the screw tightening device is arranged on the crossbeam 4, and the screw tightening device includes a servo motor 5, a reducer 6 and The screw sleeve 7, the servo motor 5 is connected with the reducer 6 through the key, the output shaft of the reducer 6 is connected with the coupling, and the coupling is connected with the replaceable screw sleeve 7, and the beam 4 is provided with a spring balancer 8 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com