Grinding disc casting, grinding disc casting mold and grinding disc molding process

A technology of casting models and grinding discs, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, so as to reduce post-processing costs and time, solve shrinkage defects, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

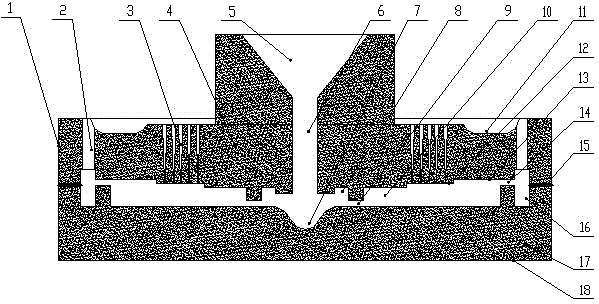

[0037] Please refer to figure 1 , a grinding disc casting, including the grinding disc main part, is characterized in that the upper plane of the grinding disc main part is designed in a stepped shape, and the inner circle of the grinding disc main part is provided with a thermal insulation slag ring, on the outer surface of the grinding disc main part The circle is provided with an outer thermal insulation overflow slag collection ring, and exhaust and slag discharge rods are evenly distributed on the thermal insulation overflow slag collection ring of the outer circle of the main part of the grinding disc.

[0038] A grinding disc casting model for making the above-mentioned grinding disc castings, comprising an upper sand box, an upper sand mold, a lower sand box, and a lower sand mold. The upper sand mold and the lower sand mold are bonded and sealed at the parting surface of the mold. A sprue is set up in the center of the sand mold, and a sprue cup is provided above the ...

Embodiment 2

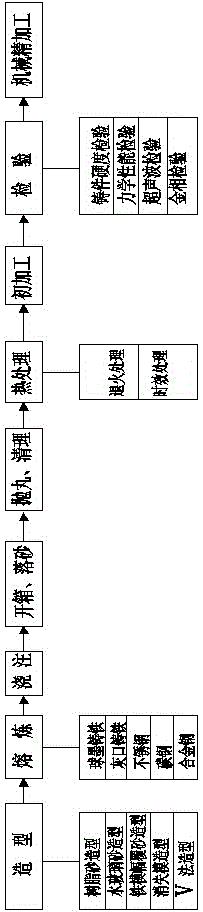

[0042] Please refer to figure 2 , grinding disc molding process, using the grinding disc casting model of embodiment one to manufacture grinding discs, the grinding disc molding process is as follows:

[0043] 1) Modeling: Use grinding discs to cast model shapes, and the modeling method adopts one of resin sand molding, water glass sand molding, iron mold sand covering molding, lost foam molding and V method modeling;

[0044] 2) Smelting: Smelting the raw material of the grinding disc to obtain molten metal. The raw material of the grinding disc is selected from ductile iron, gray cast iron, stainless steel, carbon steel and alloy steel;

[0045] 3) Pouring: pour the molten metal obtained in the above step 2) into the grinding disc casting model described in 1) to obtain a grinding disc casting;

[0046] 4) Open the box and shake out the sand;

[0047] 5) Shot blasting and cleaning: Shot blasting and cleaning the grinding disc castings obtained in the above 4) to obtain gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com