Radial forging method for forming short lead screw of inverted planetary roller screw pair

A technology of radial forging and planetary rollers, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., and can solve the problems of inability to form gear shapes, difficult material flow, and high tooth height of gears, etc. problem, to achieve the effect of less manufacturing time, high mechanical strength and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

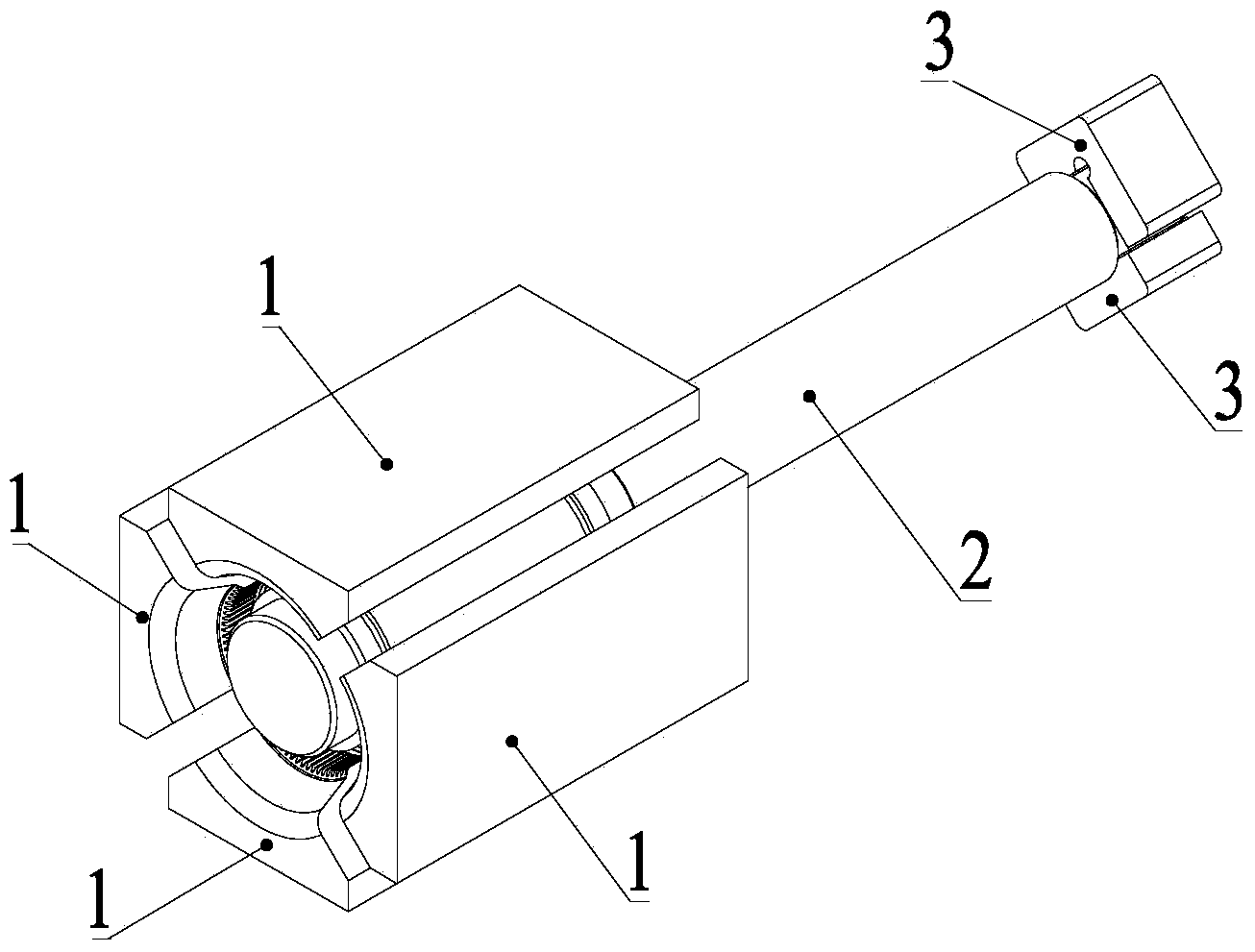

[0039] In this embodiment, four radial forging dies 1 are adopted, and the radial forging dies 1 are arrayed at equal intervals along the axis of the workpiece 2 in space. The formed reverse planetary roller screw pair short lead screw has 6 threads, 78 gear teeth, 1 mm total radial forging, and 2 passes.

[0040] A method for radially forging a reverse-type planetary roller screw auxiliary short lead screw, comprising the following steps:

[0041] Step 1, clamping workpiece 2, one end of workpiece 2 is clamped by manipulator 3;

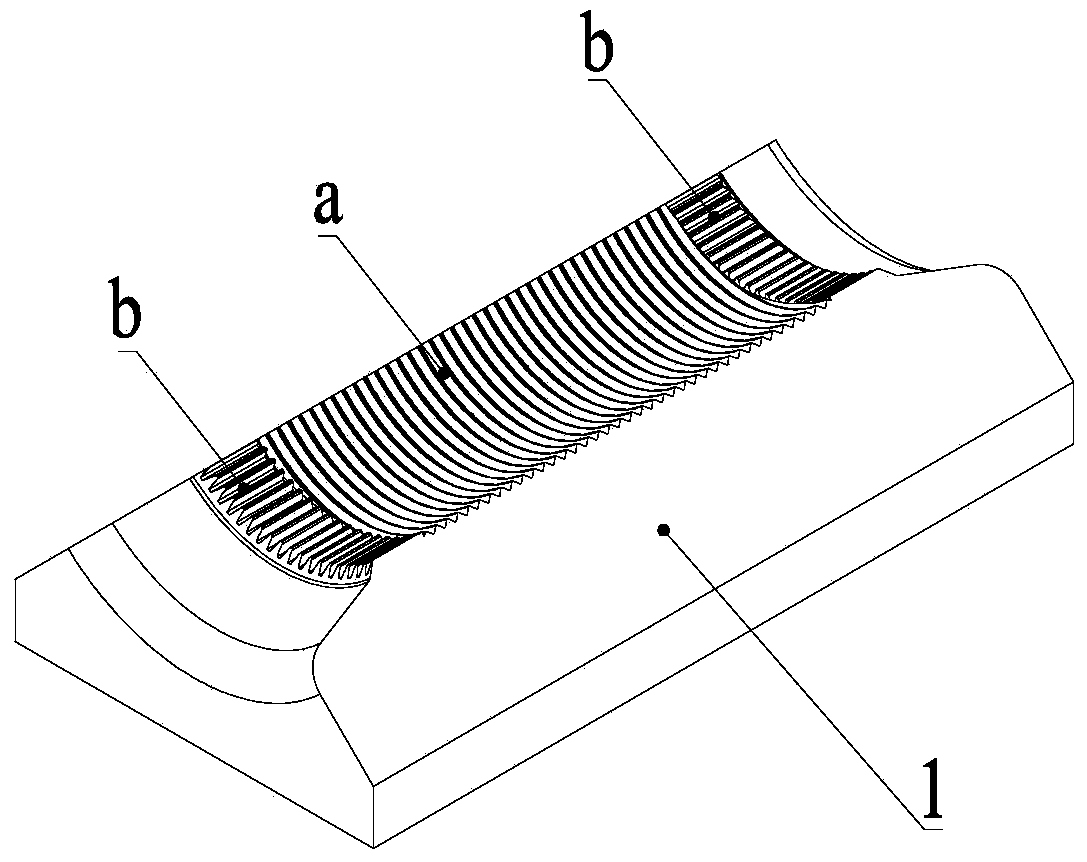

[0042] Step 2, workpiece 2 is fed axially, refer to figure 1 , the manipulator 3 holds the workpiece 2 and feeds it in the direction of the radial forging die 1, and enters the strike range of the radial forging die 1, refer to figure 2 , the radial forging die 1 has a thread segment a and a gear segment b, and the formed thread segment and the forming gear segment on the workpiece 2 are respectively aligned with the thread segment a and the gear ...

Embodiment 2

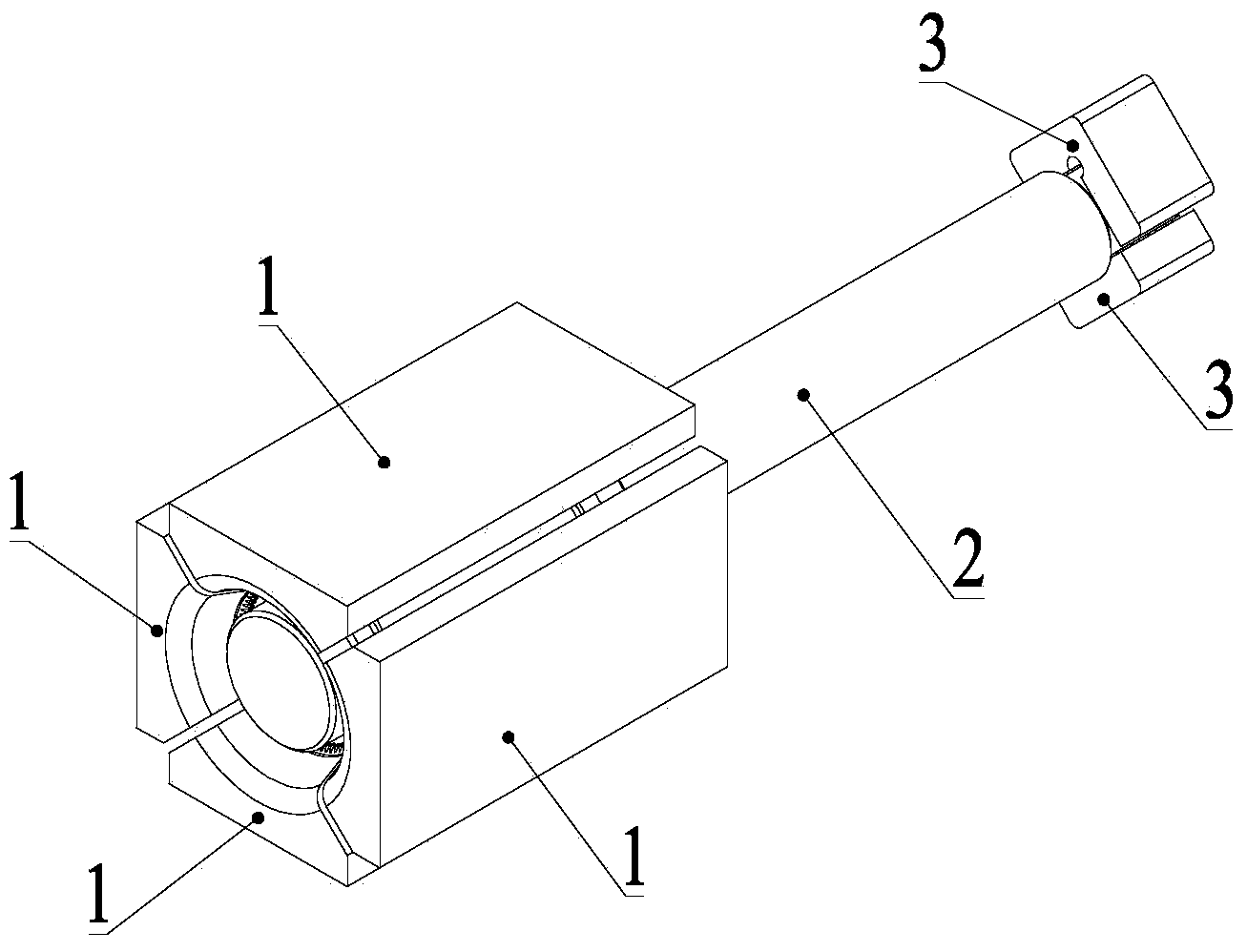

[0061] In this embodiment, four radial forging dies 1 are adopted, and the radial forging dies 1 are arrayed at equal intervals along the axis of the workpiece 2 in space. The formed reverse planetary roller screw pair short lead screw has 6 threads, 78 gear teeth, 0.75mm radial forging, and 1 pass.

[0062] A method for radially forging a reverse-type planetary roller screw auxiliary short lead screw, comprising the following steps:

[0063] Step 1, clamping workpiece 2, one end of workpiece 2 is clamped by manipulator 3;

[0064] Step 2, workpiece 2 is fed axially, refer to figure 1 , the manipulator 3 holds the workpiece 2 and feeds it in the direction of the radial forging die 1, and enters the strike range of the radial forging die 1, refer to figure 2 , the radial forging die 1 has a thread segment a and a gear segment b, and the formed thread segment and gear segment on the workpiece 2 are respectively aligned with the thread segment a and the gear segment b on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com