Large-diameter anti-cracking PE pipe

A large-diameter, pipe body technology, applied in the field of large-diameter anti-cracking PE pipes, can solve the problems of low strength, poor tensile strength, easy deformation, etc., to achieve reasonable structure, increase deformation resistance, and increase tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

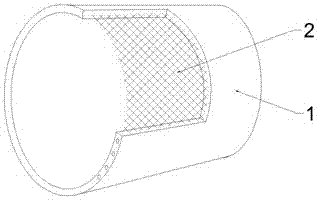

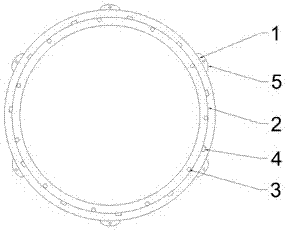

[0013] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , the large-diameter anti-crack PE pipe described in this embodiment includes a pipe body 1 made of polyethylene material, and a cylindrical reinforcement layer 2 is arranged in the middle of the pipe wall of the pipe body 1, and the reinforcement layer 2 is formed by rolling a metal mesh , the metal mesh thickness of the reinforcement layer 2 is 1-1.5mm. The inside of the reinforcement layer 2 is provided with an inner reinforcement strip 3, which is made of steel wires with a diameter of 3-5mm. They are connected and fixed by welding. The outside of the reinforcing layer 2 is provided with an outer reinforcing bar 4, and there are multiple outer reinforcing bars 4, and the outer reinforcing bar 4 is located on the outer side of the reinforcing layer 2 between adjacent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com