Structure-optimized drill rod on spiral drilling machine

A technology for auger drilling rigs and drill pipes, which is applied in the field of drill pipes with optimized structures on auger drilling rigs, which can solve problems such as easy wear, deformation of helical blades, and large soil friction, so as to reduce wear, increase anti-deformation strength, and strengthen strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

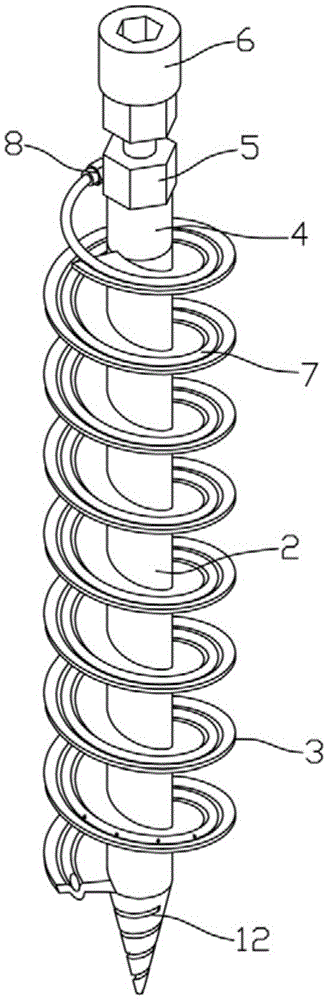

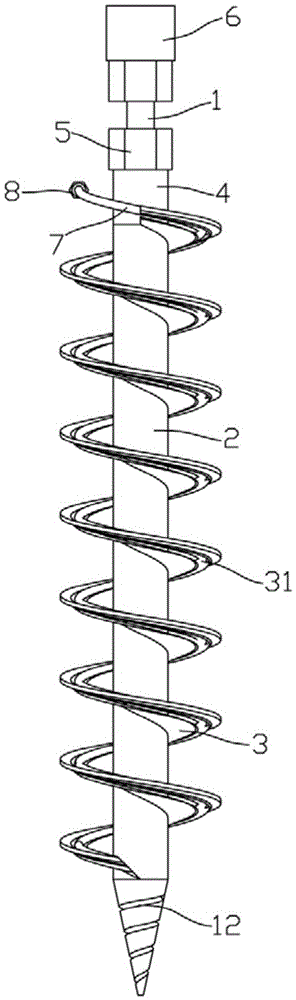

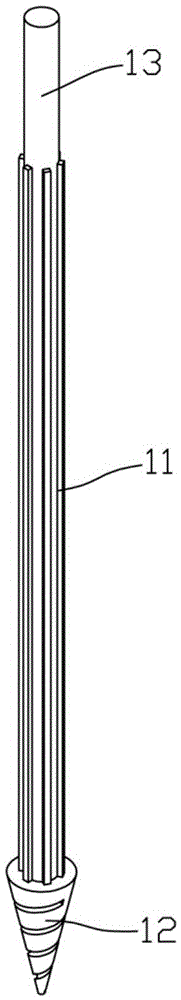

[0016] Example: see Figures 1 to 5 As shown, a drill rod with an optimized structure on an auger drill includes a rod body 1. The rod body 1 is composed of a spline shaft 11, a drill bit 12 and a stud 13. The drill bit 12 and the stud 13 are formed on the upper and lower sides of the spline shaft 11 respectively. end, the spline shaft 11 is plugged with a spline sleeve 2, and the outer wall of the spline sleeve 2 is welded and fixed with a helical blade 3. Spiral water delivery pipe 7 is welded in the tendon groove 31 of water delivery pipe 7, and the upper end of water delivery pipe 7 is fixedly connected with water pipe joint 8, and the lower end of water delivery pipe 7 is welded and fixed with spiral guide round rod 9, and guide round rod 9 is welded and fixed on the spiral In the tendon groove 31 of the blade 3 lower end, the bottom end of the guide round rod 9 and the bottom end of the helical blade 3 are formed with an inclined guide angle a, and several water outlet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com