Fifth cast beam of frame of heavy truck

A technology for heavy-duty trucks and beams, which is applied to vehicle components, substructure, transportation and packaging, etc. It can solve the problems of frame and balance suspension damage, reduce the service life of the frame, reduce the installation process, and enhance the overall anti-distortion , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

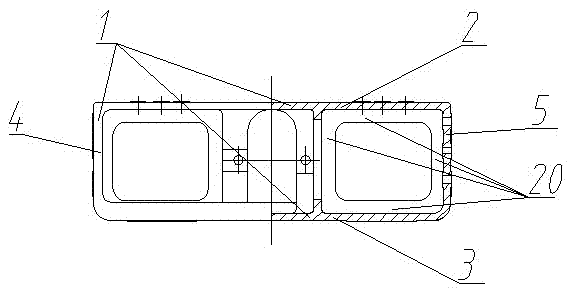

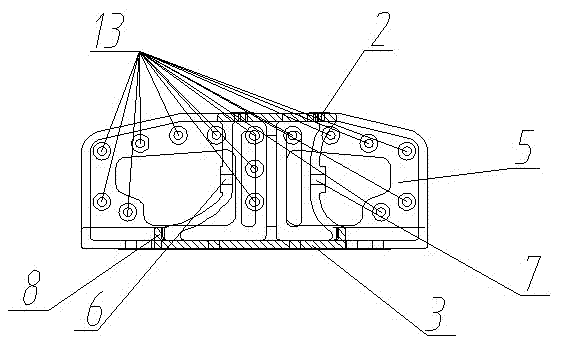

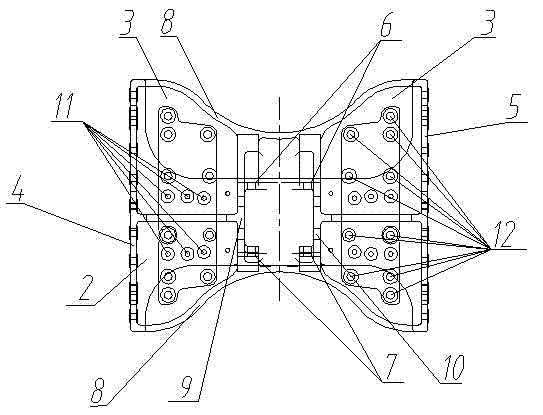

[0013] from Figure 1-Figure 4 It can be seen from the figure that a cast fifth beam of a heavy-duty truck frame (hereinafter referred to as the cast fifth beam) is characterized in that the cast fifth beam is mainly composed of a beam body 1 and a front beam set in the inner cavity of the beam body 1 The thrust rod support 7 and the rear thrust rod support 6 are composed. The beam body 1 is box-shaped with a cavity, and is mainly composed of a top plate 2, a bottom plate 3, a left side plate 4 and a right side plate 5 cast into one body. The plate 4 and the right side plate 5 are symmetrically arranged vertical panels, and front and rear weight-reducing holes are provided on the plate surface, the top plate 2 is biased forward relative to the bottom plate 3, and the bottom plate 3 is a symmetrically arranged butterfly plate, that is, the bottom plate 3 The distance between the front and rear sides of the top plate 2 is that the width of the middle part is large on the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com