Ratchet wheel of binding device

一种捆绑器、棘轮的技术,应用在运输车辆上货物捆绑的工具,捆绑工具领域,能够解决机械强度差等问题,达到提高机械强度、改善性能效果、高实用价值的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] As shown in Figure 12, the binding device is usually made up of parts such as body 8, ratchet 1, baffle plate 9, spring 10, handle 5, reel 3, side piece body 4, webbing 6 and belt hook 7. The webbing 6 is wound on the reel 3, and the end of the webbing 6 is a belt hook 7. The belt hooks 7 at both ends of the binding device are hooked on the goods or the car body when in use, and the ratchet 1 is rotated in one direction by repeatedly pulling the side body 4, so that the webbing 6 is continuously wound on the reel 3, so that the webbing 6 is tightened. Finally, the goods are tied tightly and positioned.

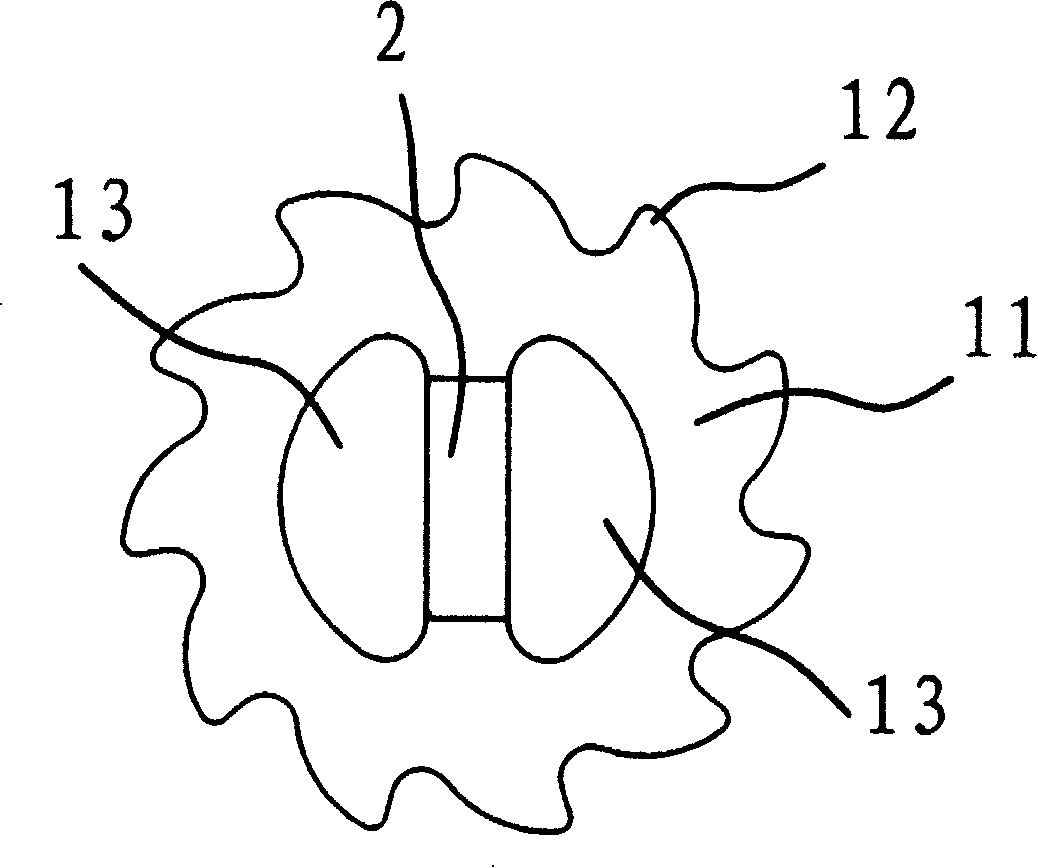

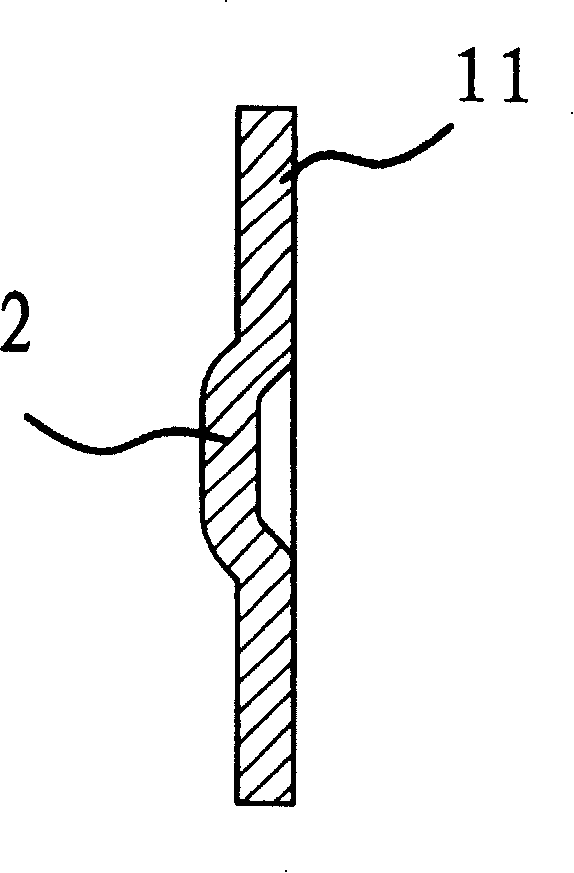

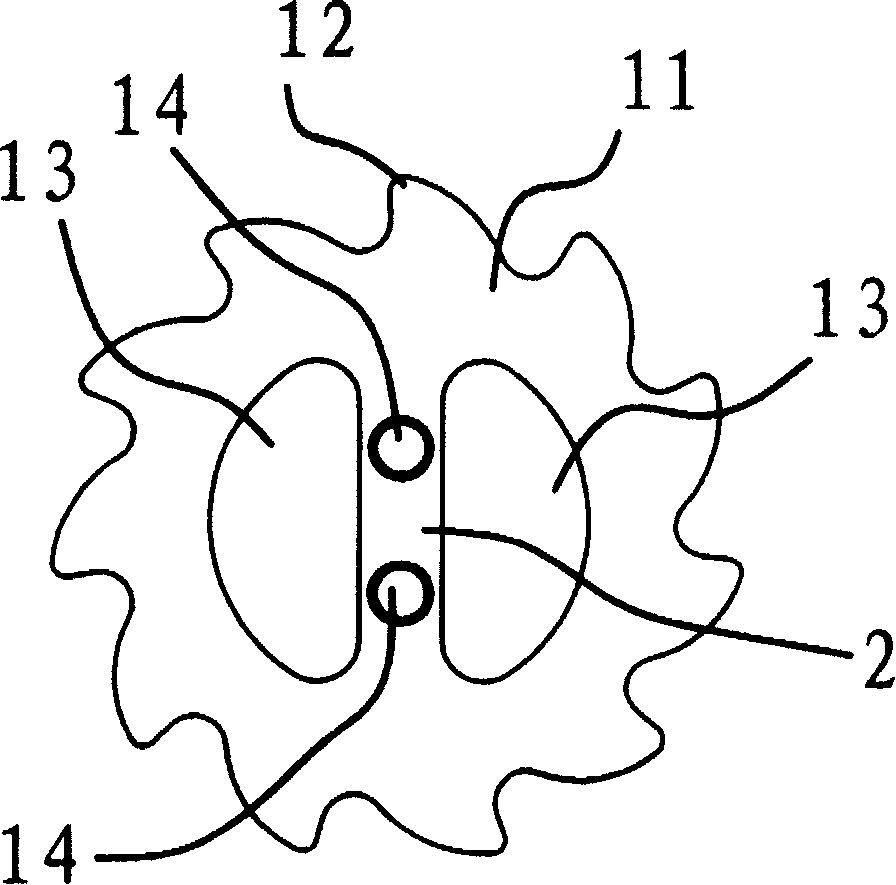

[0025] In the present invention, other structures of the binding device are the same as the common binding device, the difference lies in the improvement of the ratchet 1 . Such as figure 1 As shown, the ratchet 1 of the binder includes a wheel body 11, a ratchet 12 is arranged on the outer edge of the wheel body 11, and there are two shaft holes 13 for the reel to pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com