(NbMoTaW)100-xMx series refractory high-entropy alloy and preparation method thereof

A technology of high-entropy alloys and alloys, applied in the field of high-entropy alloys and high-temperature-resistant alloys, can solve problems such as the use of refractory high-entropy alloy materials, and achieve the effect of improving deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] above (NbMoTaW) 100-x m x It is a preparation method of a refractory high-entropy alloy, and the preparation method specifically includes the following steps:

[0039] Step 1: Use metallurgical pure elements with a purity of more than 99.9% as raw materials to remove the oxide layer and impurities of Nb, Mo, Ta, W, and put them into ethanol or acetone for ultrasonic cleaning. Cut into fine particles, O element is added in the form of metal oxide particles.

[0040] Step 2: Calculate the mass of Nb, Mo, Ta, W, C, B and oxides required for each alloy according to the atomic ratio of the design components, and then carry out weighing and proportioning for smelting and preparing alloys;

[0041] Step 3: Use a vacuum non-consumable tungsten electrode electric arc furnace to melt the alloy, and vacuum the sample chamber. When the vacuum degree is higher than 5*10 -3 Pa, filled with industrial argon;

[0042] Step 4: Pre-alloying is first smelted according to the differenc...

Embodiment 1

[0045] (NbMoTaW) 99.96 B 0.04 Alloy preparation and characterization:

[0046] (1) Raw material preparation: Weigh clean raw materials separately, take Nb: 3.324g, Mo: 3.466g, Ta: 6.536g, W: 6.641g, B: 0.0006g;

[0047] (2) Alloy smelting: first, B and a certain quality of Nb are smelted into a pre-alloy, so that B is completely melted in Nb to form a niobium alloy; then two kinds of raw materials are selected according to the difference in melting point to smelt an intermediate alloy, and through multiple smelting. The elements of the master alloy are evenly distributed; finally, the two master alloys are combined into the same crucible, and the alloy ingot with uniform distribution of elements is formed by multiple melting;

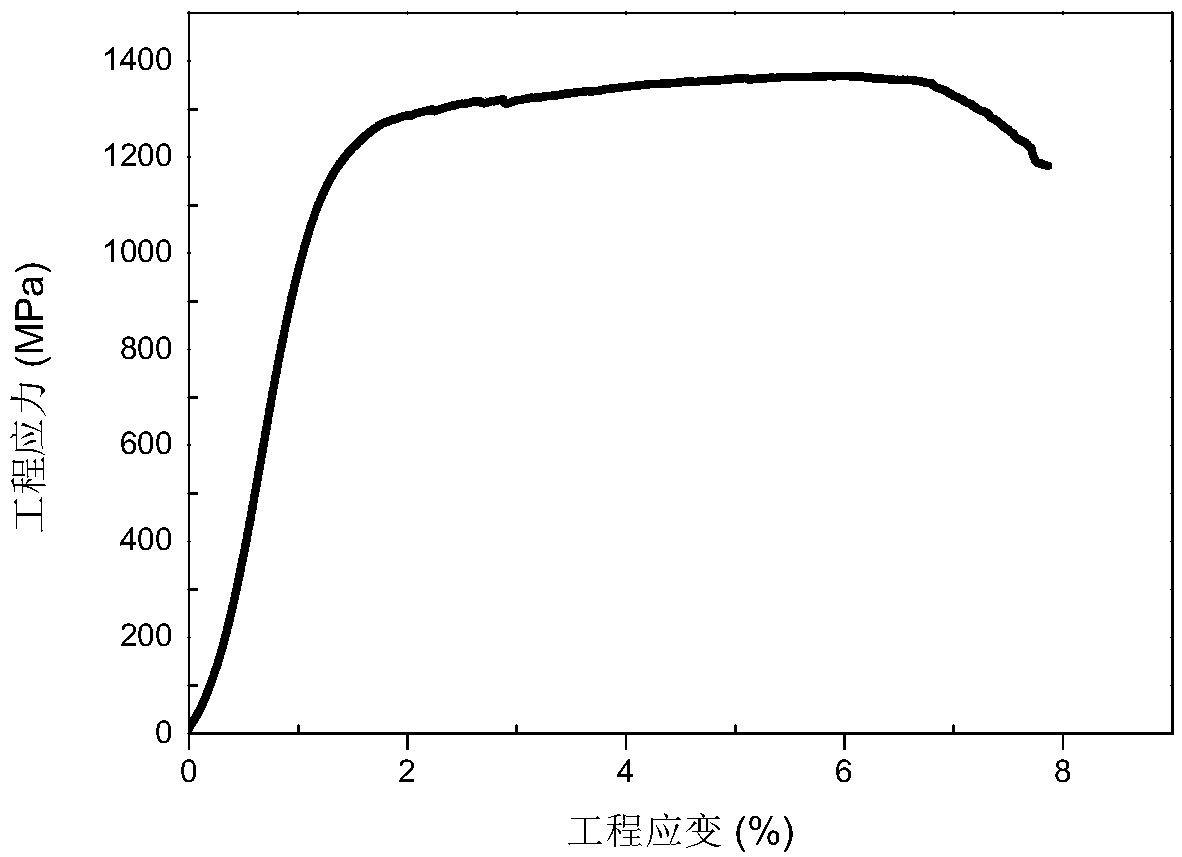

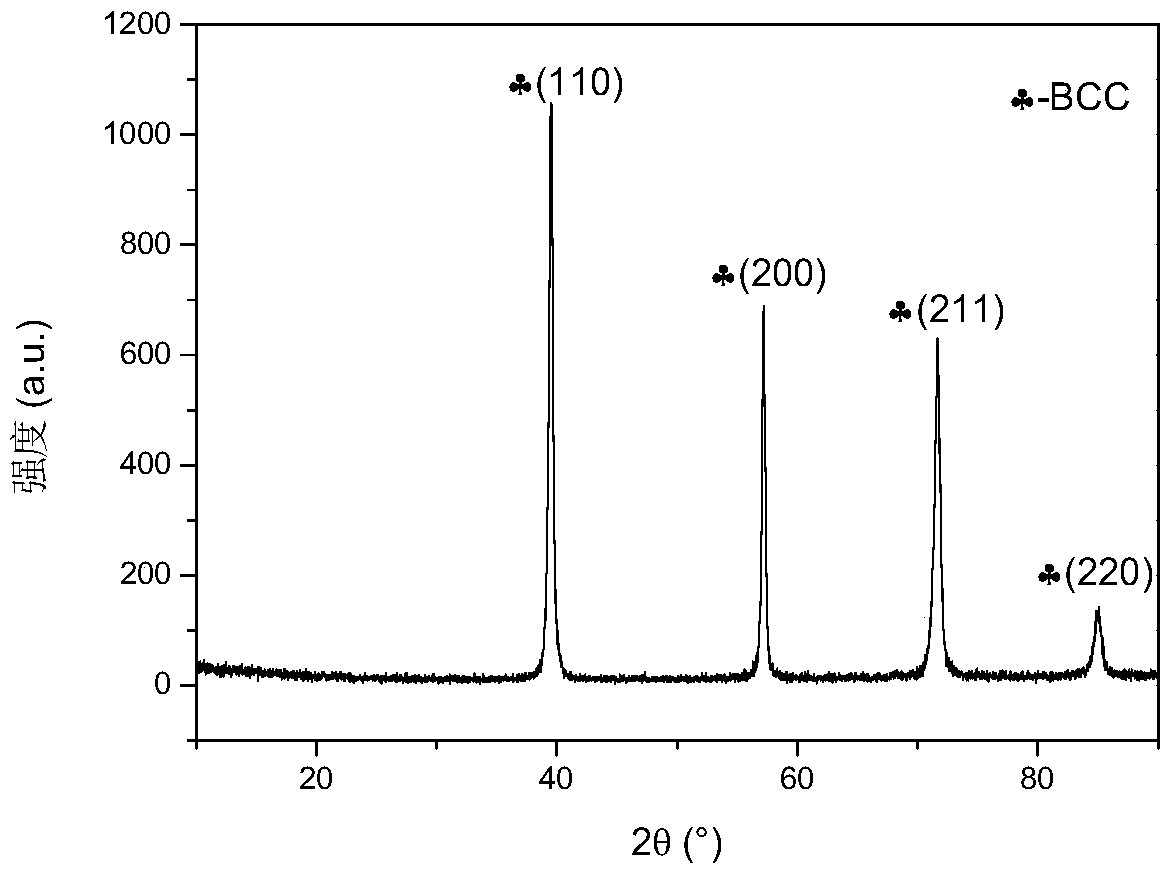

[0048] (3) Material mechanical performance test and phase characterization: From the alloy ingots refined above, a cylindrical sample with a height-to-diameter ratio of 2:1 was taken out by wire cutting, and its surface was polished. The mechanical p...

Embodiment 2

[0051] (NbMoTaW) 99.5 B 0.5 Alloy preparation and characterization:

[0052] (1) Raw material preparation: Weigh the clean raw materials separately, take Nb: 3.354g, Mo: 3.465g, Ta: 6.534g, W: 6.638g, B: 0.0078g;

[0053] (2) Alloy smelting: first, B and a certain quality of Nb are smelted into a pre-alloy, so that B is completely melted in Nb to form a niobium alloy; then two kinds of raw materials are selected according to the difference in melting point to smelt an intermediate alloy, and through multiple smelting. The elements of the master alloy are evenly distributed; finally, the two master alloys are combined into the same crucible, and the alloy ingot with uniform distribution of elements is formed by multiple melting;

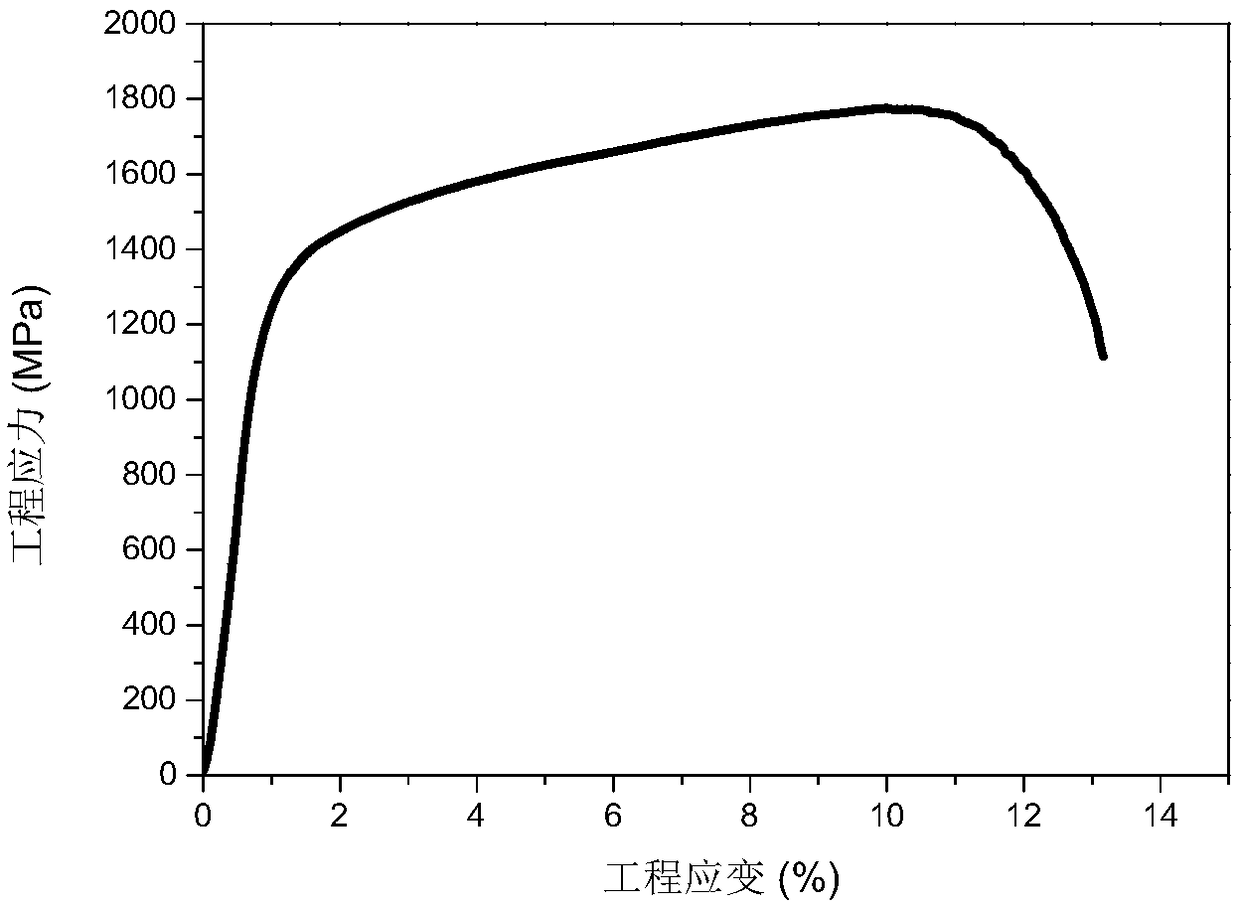

[0054] (3) Material mechanical performance test and phase characterization: From the alloy ingots refined above, a cylindrical sample with a height-to-diameter ratio of 2:1 was taken out by wire cutting, and its surface was polished. The mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature compressive strength | aaaaa | aaaaa |

| Room temperature compressive strength | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com