Economical ultralow-temperature steel and preparation method thereof

An ultra-low temperature and economical technology, applied in the field of ultra-low temperature steel, can solve the problems of limiting the application range of ultra-low temperature steel, increasing solution treatment and tempering, and unfulfilled service conditions, so as to achieve twinning-induced plasticity inhibition, improve plasticity, The effect of reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

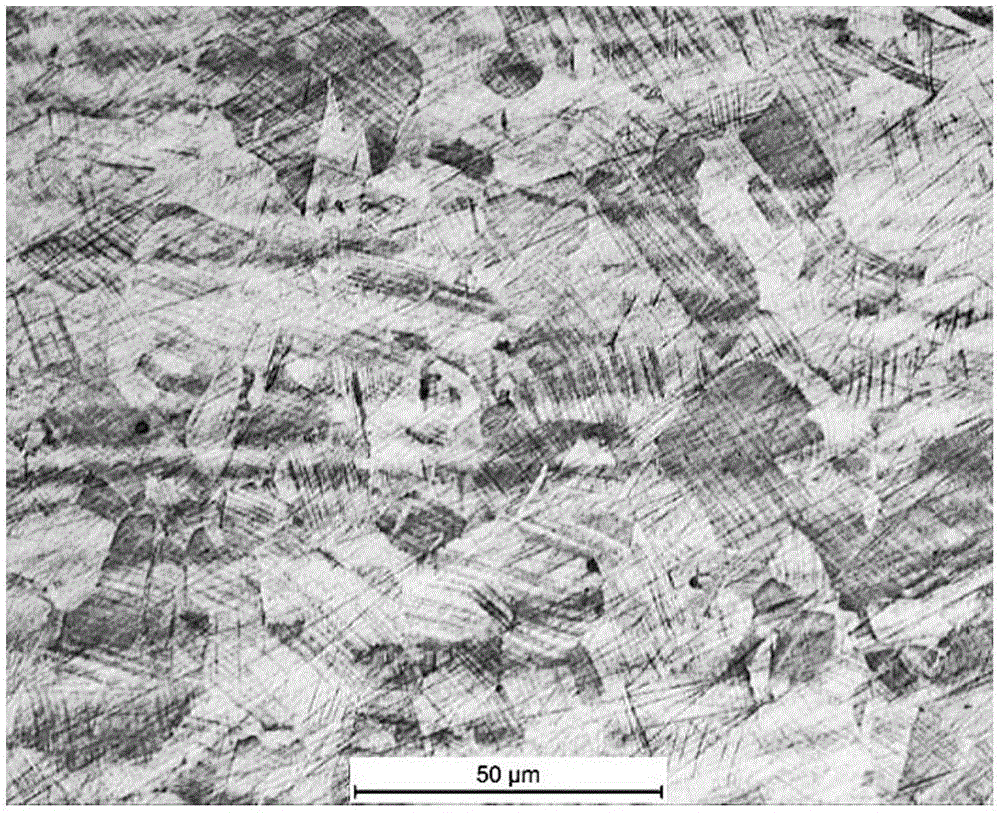

[0030] This example is an economical ultra-low temperature steel plate with a thickness of 25mm, and its chemical composition and mass fraction are 0.45%C, 24%Mn, 0.3%Si, 2.5%Cr, 0.5%Cu, 0.04%N, 0.01% %Al, 0.019% P, 0.002% S, and the balance of Fe and impurity elements, austenite structure at room temperature, R p0.2 =435MPa, R m =800MPa, A=57%, -196℃ Charpy impact test KV 2 =126J.

[0031] The preparation of the above-mentioned economical ultra-low temperature steel is carried out according to the following steps:

[0032] Put a 260mm thick blank into a heating furnace and heat it to 1080°C for 180 minutes. The chemical composition and mass fraction of the blank are 0.45%C, 24%Mn, 0.3%Si, 2.5%Cr, 0.5%Cu, 0.04% N, 0.01%Al, 0.019%P, 0.002%S, and the balance of Fe and impurity elements;

[0033] The heated slab is rolled, and the rolling mill reduction procedure is 220mm -208mm -166mm -133mm -106mm -80mm -60mm -45mm -34mm -25mm. The final rolling temperature is 995°C;

[00...

Embodiment 2

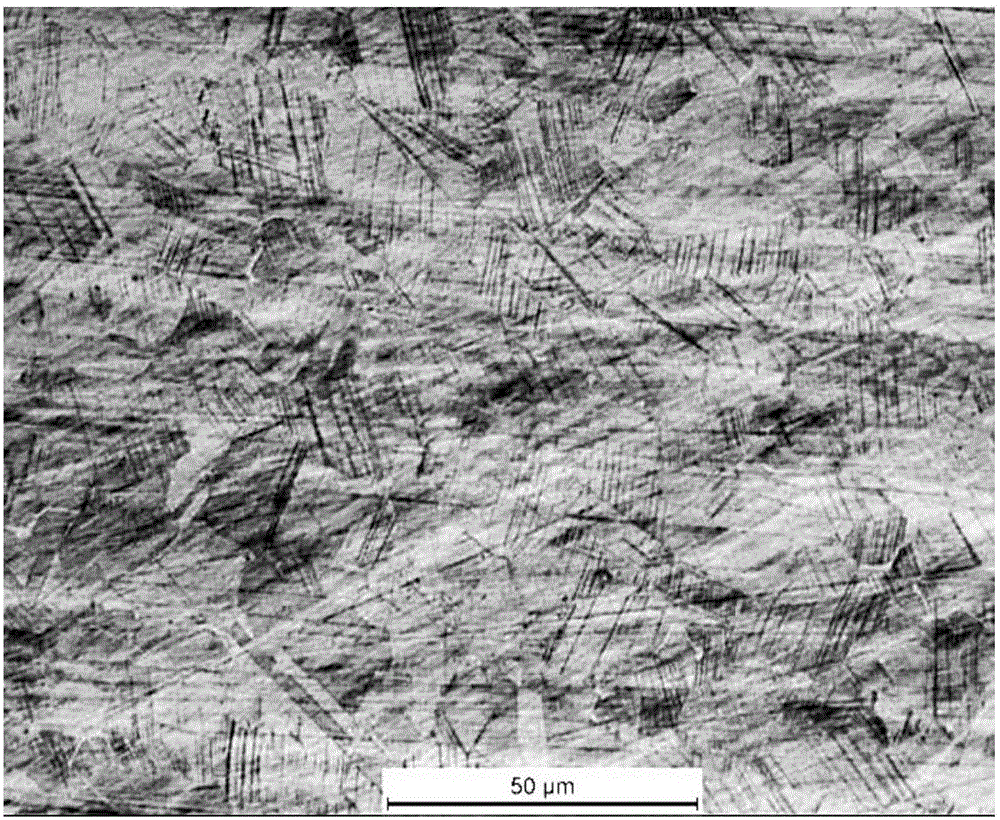

[0037] This example is an economical ultra-low temperature steel plate with a thickness of 50mm, and its chemical composition and mass fraction are 0.4%C, 28%Mn, 0.1%Si, 4%Cr, 0.3%Cu, 0.01%N, 0.025% %Al, 0.014% P, 0.01% S, and the balance of Fe and impurity elements, austenite structure at room temperature, R p0.2 =455MPa, R m =880MPa, A=50%, -196℃ Charpy impact test KV 2 =80J.

[0038]The preparation of the above-mentioned economical ultra-low temperature steel is carried out according to the following steps:

[0039] Put a 340mm thick blank into a heating furnace and heat it to 1150°C and hold it for 120min. The chemical composition and mass fraction of the blank are 0.4%C, 28%Mn, 0.1%Si, 4%Cr, 0.3%Cu, 0.01% N, 0.025%Al, 0.014%P, 0.01%S, and the balance of Fe and impurity elements;

[0040] The heated slab is rolled, and the rolling mill reduction procedure is 340mm-290mm-256mm-204mm-164mm-131mm-105mm-84mm-67mm-50mm. The final rolling temperature is 970°C;

[0041] The ...

Embodiment 3

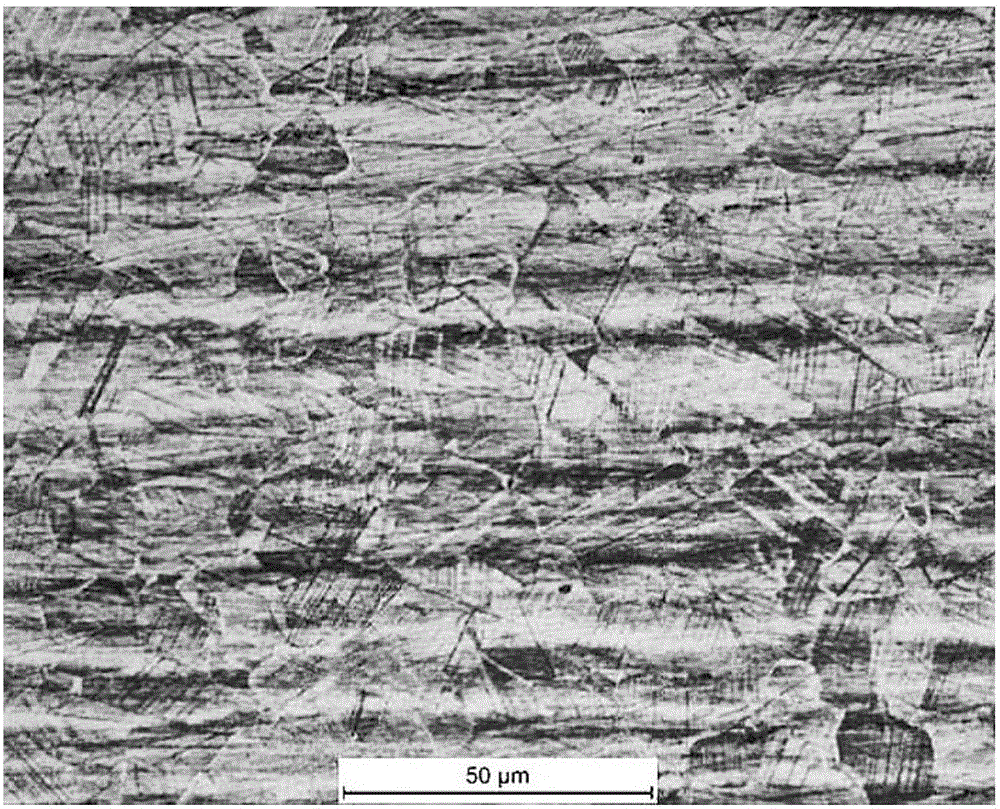

[0044] This example is an economical ultra-low temperature steel plate with a thickness of 12mm, and its chemical composition and mass fraction are 0.3%C, 20%Mn, 0.5%Si, 5.5%Cr, 0.8%Cu, 0.10%N, 0.05% %Al, 0.03%P, 0.004%S, and the balance of Fe and impurity elements, austenite structure at room temperature, R p0.2 =400MPa, R m =840MPa, A=66%, -196℃ Charpy impact test KV 2 =151J.

[0045] The preparation of the above-mentioned economical ultra-low temperature steel is carried out according to the following steps:

[0046] Put a 150mm thick blank into a heating furnace and heat it to 1220°C for 90 minutes. The chemical composition and mass fraction of the blank are 0.3%C, 20%Mn, 0.5%Si, 5.5%Cr, 0.8%Cu, 0.10% N, 0.05%Al, 0.03%P, 0.004%S, and the balance of Fe and impurity elements;

[0047] Rolling the heated slab, the rolling mill reduction regulation is 150mm -128mm -108mm -87mm -69mm -55mm -39mm -27mm -18mm -12mm, and the final rolling temperature is 1030°C;

[0048] The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com