Titanium alloy with high strength, high plasticity and good fracture toughness and preparing technology of titanium alloy

A fracture toughness and preparation process technology, applied in the field of material science, can solve the problems of high addition amount, difficult alloy melting, low elongation, etc., and achieve the effect of high plastic fracture toughness, high strength level, and good fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with embodiment.

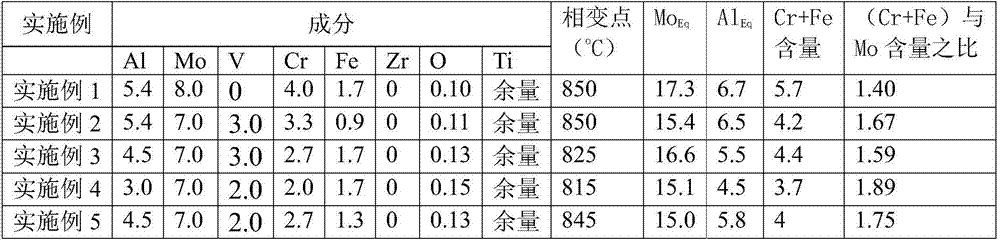

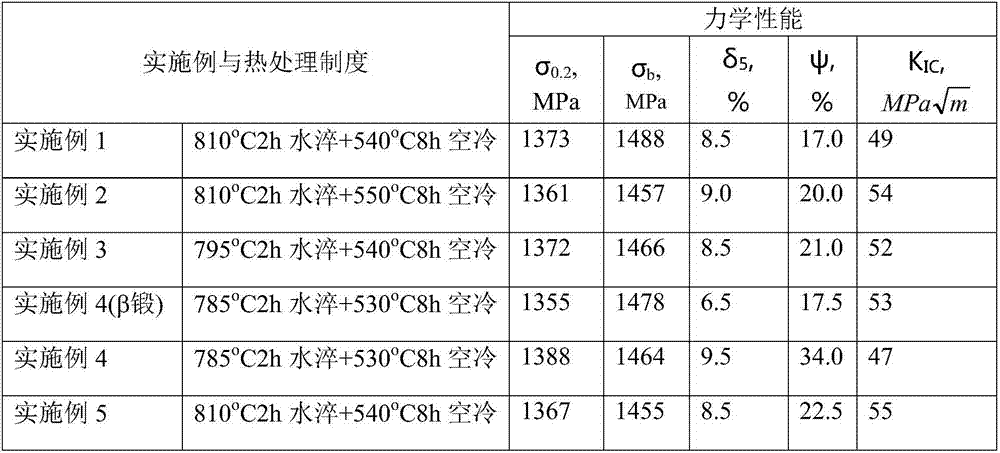

[0042] The alloy composition of each embodiment is shown in Table 1. After three vacuum consumable smelting, alloy ingots with the composition shown in Table 1 were prepared, and the phase transition point was measured by metallographic method. The ingot was free forged for multiple times, and the last forging in Examples 1, 2, 3 and 5 was in the two-phase region, the heating temperature was 750°C, and the deformation was 40%. In Example 4, two processes were used for the last forging: ① two-phase zone forging heated at 750°C (30% deformation) and ② single-phase zone forging heated at 850°C (60% deformation). All examples end up with rod-shaped billets of 60×60×L (length). The forgings were subjected to solution and aging heat treatment, and their tensile properties and fracture toughness were tested. The mechanical properties after heat treatment are given in Table 2, where σ 0.2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com