Quasi crystal phase fortified magnesium lithium alloy and its preparation method

A technology of magnesium-lithium alloy and quasi-crystalline phase, which is applied in the field of high-strength magnesium-lithium alloy and its preparation, can solve the problems of low density and strength, and achieve good plasticity and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] I), alloy composition

[0031] Configure 15 kilograms of lithium-containing magnesium alloy materials according to the following proportions, and the elements taken out are: 1200 grams of lithium (Li), 480 grams of zinc (Zn), 375 grams of magnesium-yttrium master alloy (Mg-24%Y) and the balance Magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-8%Li-3.2Zn-0.6Y.

[0032] II), alloy smelting and casting

[0033] The alloy is smelted in a 15 kg capacity crucible and electric resistance furnace. The crucible and casting molds are made of mild steel. Taking Example 1 as an example, the smelting and casting process of the alloy will be described in detail below.

[0034] 1) Set the target temperature of the crucible to 720°C and start heating; then preheat various ingredients such as pure magnesium, pure zinc, magnesium-yttrium intermediate alloy, pure lithium, etc. 2% covering agent (LiCl and LiF, weight ratio of 3:1) was baked in an oven; the ca...

Embodiment 2

[0050] I), alloy composition

[0051] Configure 15 kilograms of lithium-containing magnesium alloy materials according to the following proportions, and the elements taken out are: 1200 grams of lithium (Li), 975 grams of zinc (Zn), 750 grams of magnesium-yttrium master alloy (Mg-24%Y) and the balance Magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-8%Li-6.5Zn-1.2Y.

[0052] II), alloy smelting and casting

[0053] The smelting and casting of reference embodiment 1. The difference is that the zinc (Zn) and yttrium (Y) contents of the two are different.

[0054] III), hot extrusion processing

[0055] Referring to the extrusion process of Example 1.

[0056] IV), microstructure characterization

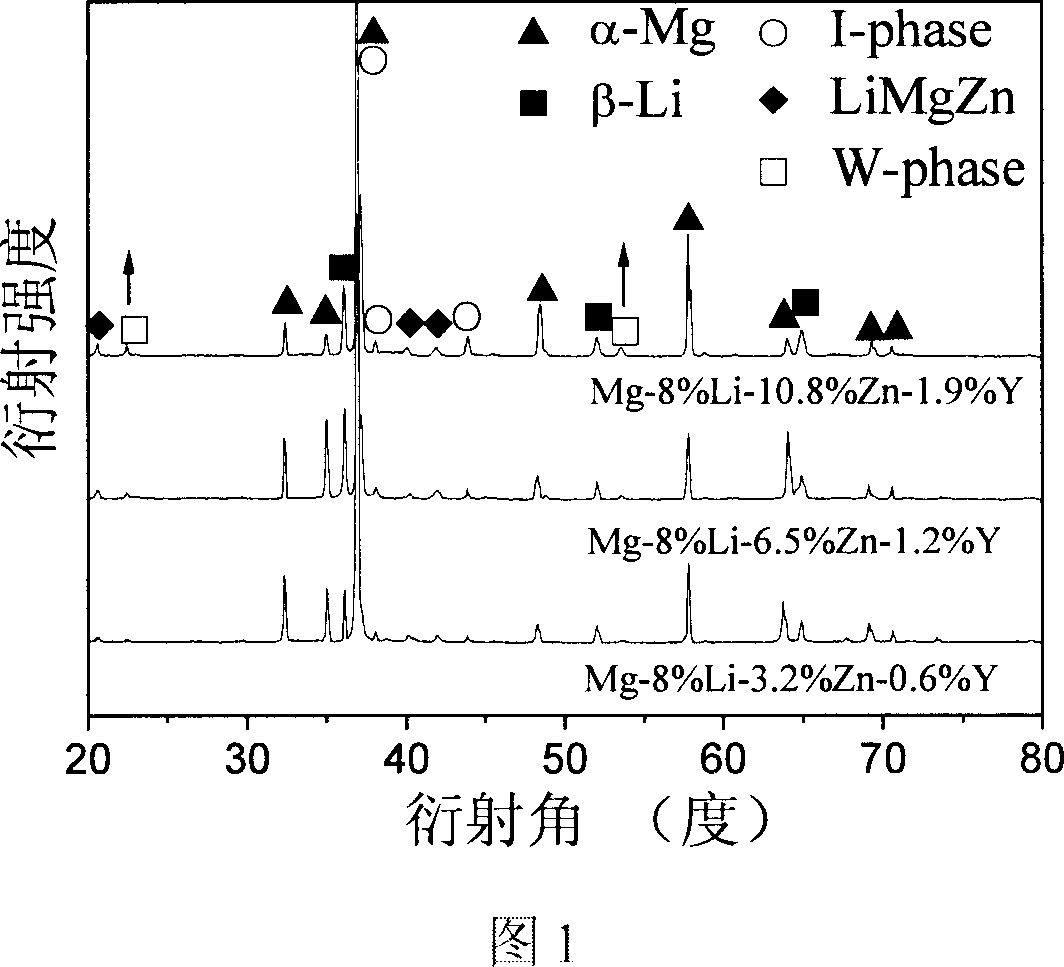

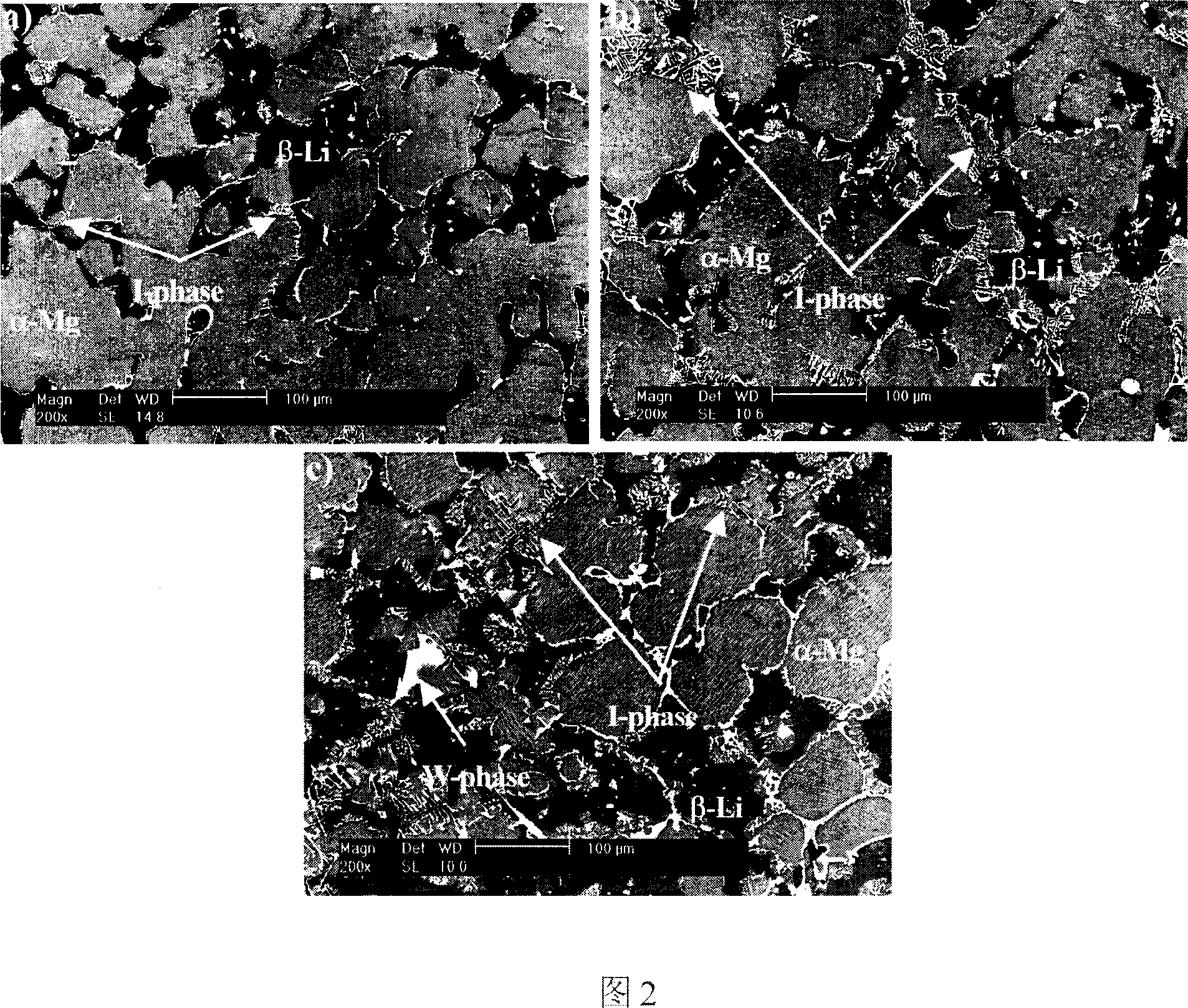

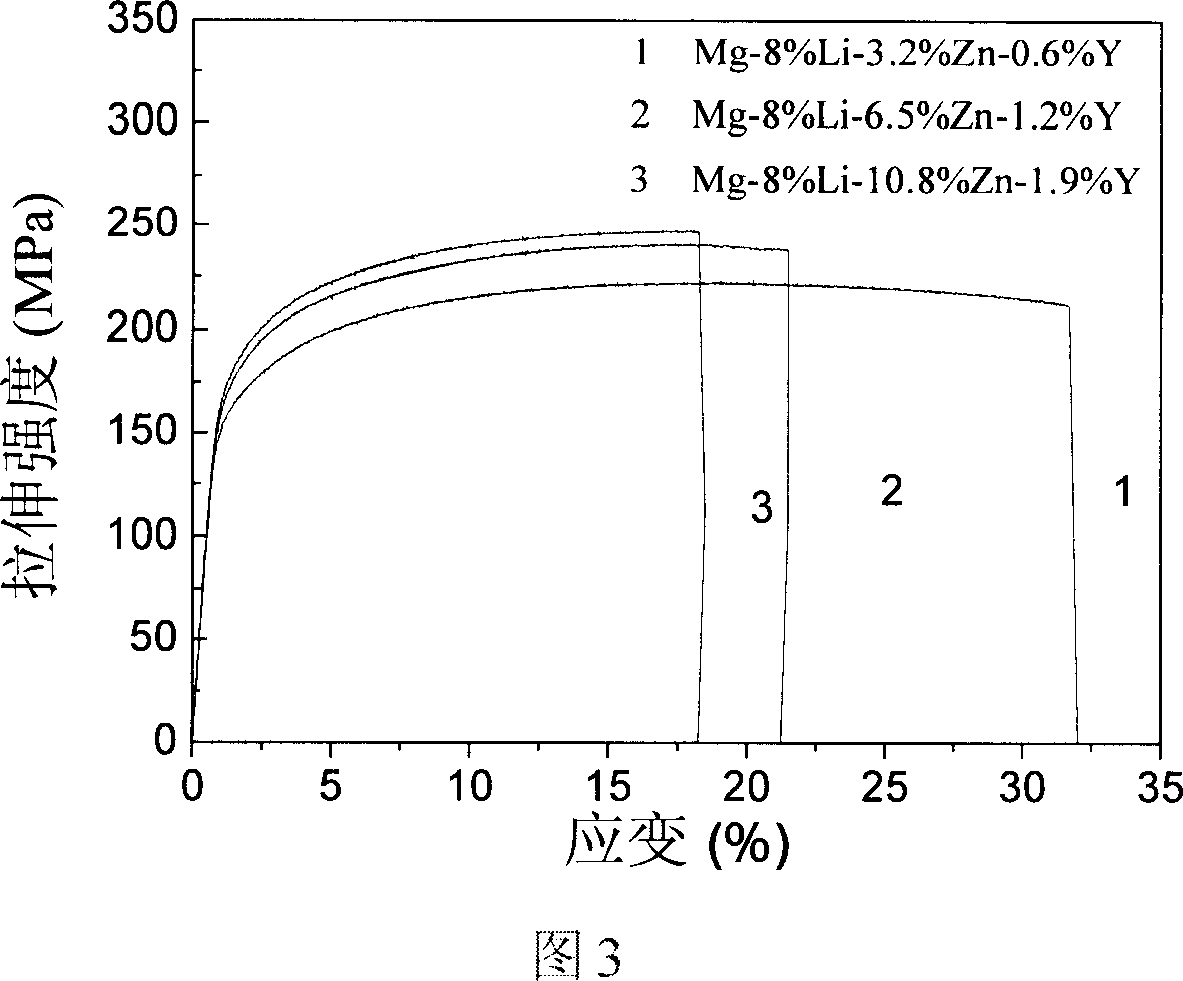

[0057] Refer to the microstructure characterization of Example 1. The main phases in the alloy are α-Mg, β-Li, LiMgZn, Mg 3 Zn 6 Y (quasicrystalline phase I-phase) and Mg 3 Zn 3 Y (W-phase), the corresponding X-ray spectrum is listed on the accompan...

Embodiment 3

[0061] I), alloy composition

[0062] Configure 15 kilograms of lithium-containing magnesium alloy materials according to the following proportions. The elements taken out are: lithium (Li) 1200 grams, zinc (Zn) 1620 grams, magnesium yttrium master alloy (Mg-24%Y) 1187 grams and the balance Magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-8%Li-10.8Zn-1.9Y.

[0063] II), alloy smelting and casting

[0064] The smelting and casting of reference embodiment 1. The difference is that the zinc (Zn) and yttrium (Y) contents of the two are different.

[0065] III), hot extrusion processing

[0066] Referring to the extrusion process of Example 1.

[0067] Iv), microstructure characterization

[0068] Refer to the microstructure characterization of Example 1. The main phases in the alloy are α-Mg, β-Li, LiMgZn, Mg 3 Zn 6 Y (quasicrystalline phase I-phase) and Mg 3 Zn 3 Y(W-phase), the corresponding X-ray spectrum is listed on accompanying drawing 1;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com