60-steel hot rolling coil rod with high strength and high plasticity and production method thereof

A technology of hot-rolled wire rod and production method, applied in metal rolling, temperature control, metal rolling, etc., can solve problems such as inability to meet high requirements, increased strength, and decreased plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

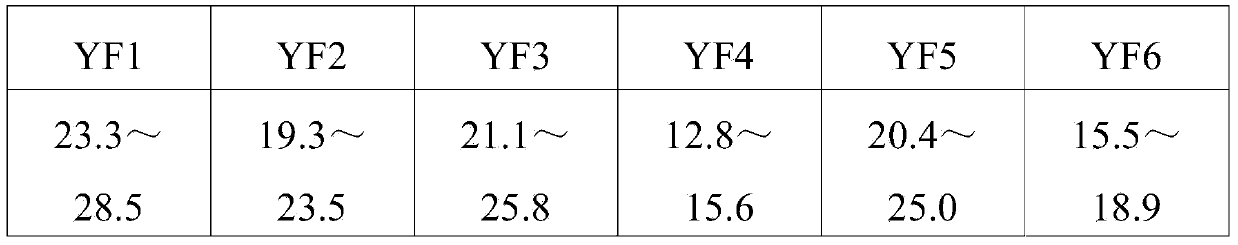

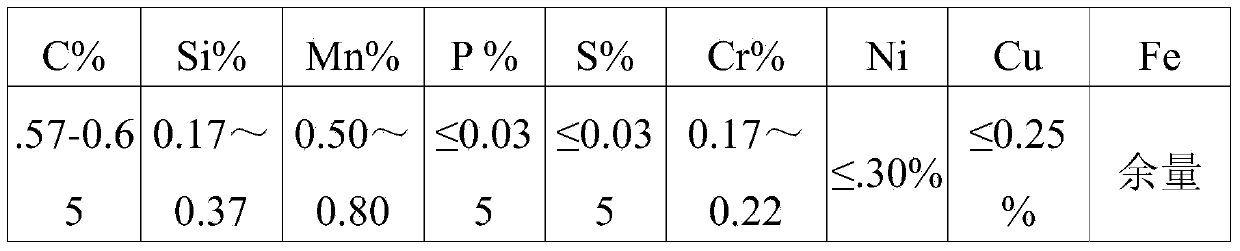

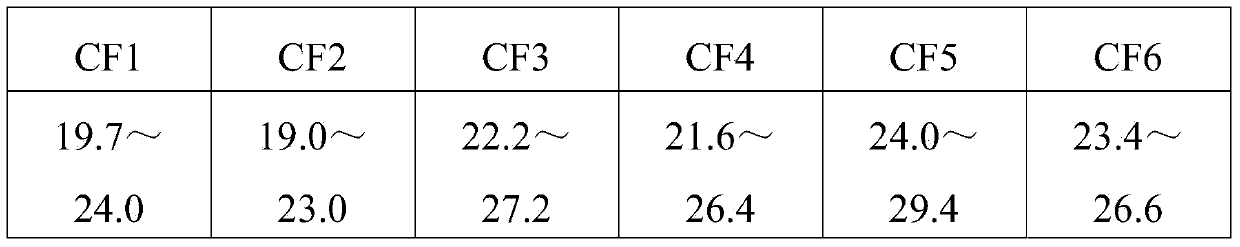

[0080] High-strength and high-plasticity 60 steel hot-rolled wire rod, its chemical composition is composed of the following substances by weight percentage (%): C0.60%, Si0.26%, Mn0.74%, Cr0.19%, P≤0.020%, S≤0.001%, Ni≤0.30%, Cu≤0.25%, and the rest is Fe. The chemical composition is listed in Table 1; the tensile strength of the wire rod reaches 990-1060Mpa, the area shrinkage rate reaches 50-60%, and the cable low body rate reaches 85-90%, which are listed in Table 2.

[0081] The production method of high-strength and high-plasticity 60 steel hot-rolled wire rod is carried out according to the following steps:

[0082] 1. Smelting

[0083] Adopt converter or electric furnace smelting and tapping end point control: [C]≥0.06%, [P]≤0.022%, [S]≤0.030%; tapping temperature: 1630~1670℃; Slag stopper, add slag stop rod or slag stopper cone when 4 / 5 of steel is tapped; alloy and recarburizer are added with steel flow, alloy addition time: start to add when 1 / 5 of steel is tapped,...

Embodiment 2

[0131] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

Embodiment 3

[0133] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com