High-temperature electrostatic precipitation system

An electrostatic dust removal and high temperature technology, applied in the field of environmental protection dust removal equipment, can solve the problems of low dust removal efficiency of the cyclone dust collector, large pressure loss of the dust collector, and large operating resistance, so as to improve the quality of subsequent condensed tar and other gasification products , Purify gas, improve energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

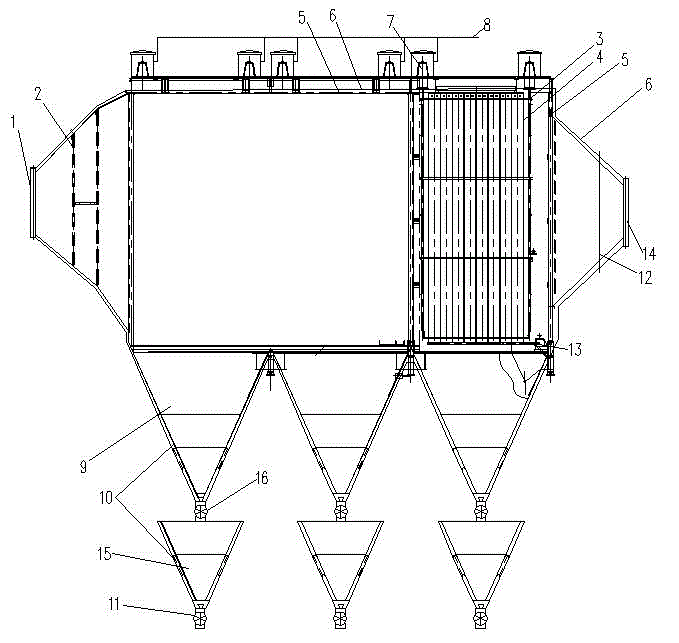

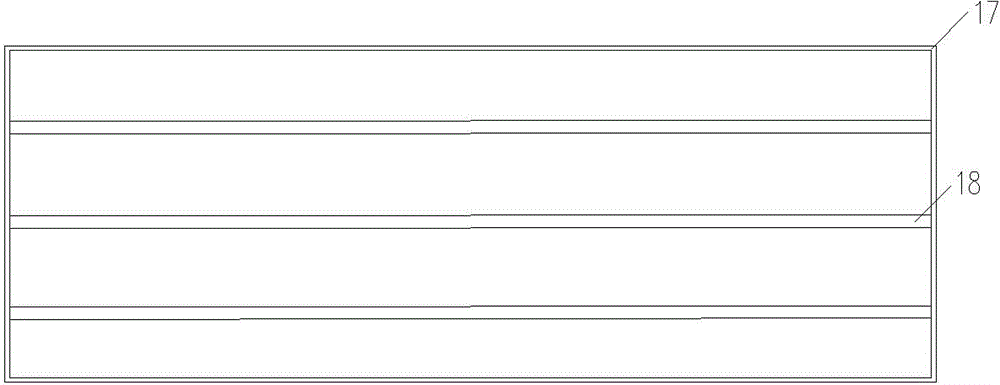

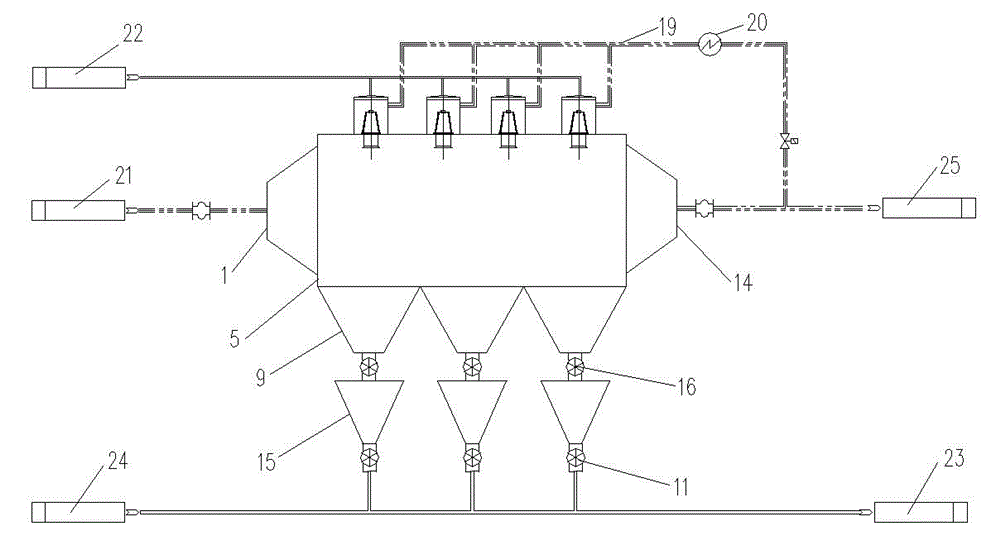

[0025] refer to Figure 1~3 , a high-temperature electrostatic precipitator system, the system includes a gas inlet 1, a dust collector housing 5, a gas outlet 14 and a layered ash hopper, the left and right ends of the dust collector housing 5 are respectively connected to the gas inlet 1, the gas The outlet 14 is connected, and the lower end of the dust collector housing 5 is connected with the layered ash hopper. The connection between the gas inlet 1 and the dust collector housing 5, and the connection between the dust collector housing 5 and the layered ash hopper are all equipped with corresponding room for expansion. The expansion space is set according to the required temperature range and shell size. Taking 800°C as an example, a thermal expansion space with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com