Method for utilizing rolling friction to centralize piston rod to do reciprocating motion and actuating device for utilizing rolling friction to centralize piston rod to do reciprocating motion through implementing method

A technology of rolling friction and reciprocating motion, applied in the field of rolling friction righting piston rod reciprocating motion, rolling friction righting piston rod reciprocating motion driving device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

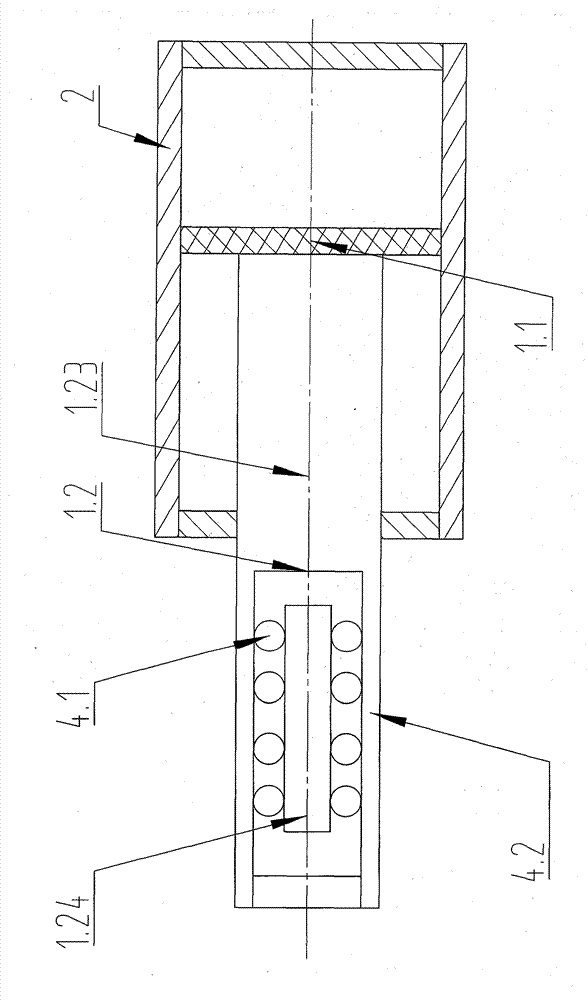

[0136] figure 1 It is the centralizer hydraulic drive device described in Embodiment 1, which includes a piston rod 1, a cylinder body 2, and a control member 3. The device also includes a centralizer 4, and the centralizer 4 includes a guide rolling body 4.1 and a guide rolling body support 4.2 , the guide rolling body support 4.2 is integrated with the cylinder body 2, the piston rod 1 includes the piston 1.1, the cylinder rod 1.2, the piston 1.1 is connected separately with the cylinder rod 1.2, the piston 1.1 is arranged in the cylinder body 2, between the piston and the cylinder body A seal is provided, and the guide rolling body 4.1 is arranged between the guide rolling body support 4.2 and the cylinder rod 1.2. Under the control of the control part 3, the piston 1.1 drives the cylinder rod 1.2 to reciprocate, and the guide rolling body 4.1 fits the guide rolling body The support member 4.2 and the cylinder rod 1.2 rotate to straighten the movement direction of the cyli...

Embodiment 2

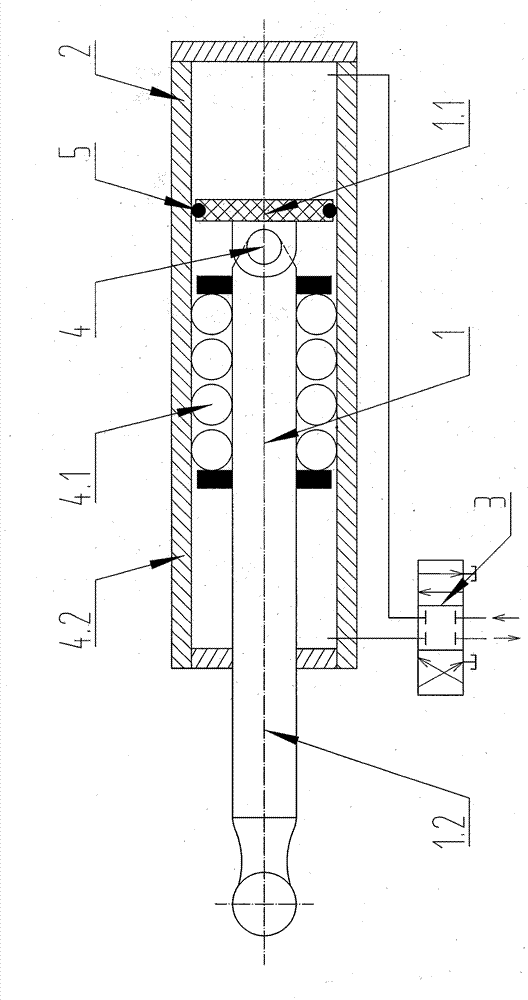

[0144] figure 2 It is the centralizer hydraulic drive device described in Example 2, the guide rolling element support 4.2 is separated from the cylinder body 2, the guide rolling element 4.1 is arranged outside the cylinder body 2, the piston 1.1 and the cylinder rod 1.2 are integrated, and the piston 1.1 There is a piston rolling body 6 between the cylinder body 2, the piston 1.1 is separated from the piston rolling body 6, the piston rolling body 6 is separated from the guide rolling body 4.1, and the piston rolling body 6 supports the rolling friction reciprocating motion of the piston 1.1 and the cylinder body 2 , The sealing element 5 is arranged at both ends of the piston rolling body 6, and the sealing element 5 can play a sealing role, but not a supporting role.

[0145] The piston rolling body 6 can be arranged around the piston 1.1 or on one side of the piston 1.1 or on two or more sides of the piston 1.1.

[0146] The piston 1.1 and the piston rolling body 6 can ...

Embodiment 3

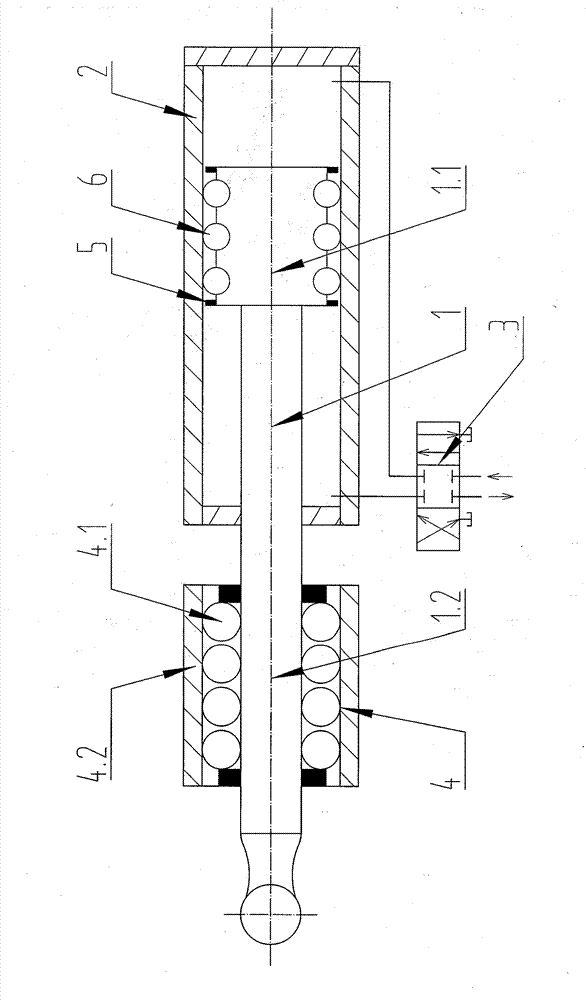

[0149] image 3 It is the centralizer hydraulic drive device described in Embodiment 3, the guide rolling element support 4.2, the cylinder rod 1.2 includes a limit structure 7, the limit structure 7 is a guide rolling element limit structure, and the guide rolling element 4.1 is arranged on the guide rolling element Body limiting structure, the guiding rolling body limiting structure limits the rolling space of the guiding rolling body 4.1.

[0150] The guide rolling body limiting structure is the raceway 7.1, which can also be a recirculating raceway or a barrel or a pit or a reciprocating stroke section or a cage or a limiting plate or a limiting ring or a limiting sleeve or a limiting platform or Limit rod or limit shaft or limit groove or spherical convex or boss or bearing or inner body and outer sleeve or oval or dumbbell-shaped or cylindrical or conical or circular or roller or table-shaped column or table-shaped ball Or table-shaped drum or groove-shaped column or gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com