Two-phase flow jet-type boosting heat exchanger

A heat exchanger and jet technology, applied in the field of heat exchange, can solve the problems of insignificant energy saving effect and high operating cost, and achieve the effect of simple structure, easy installation of instruments, and small quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

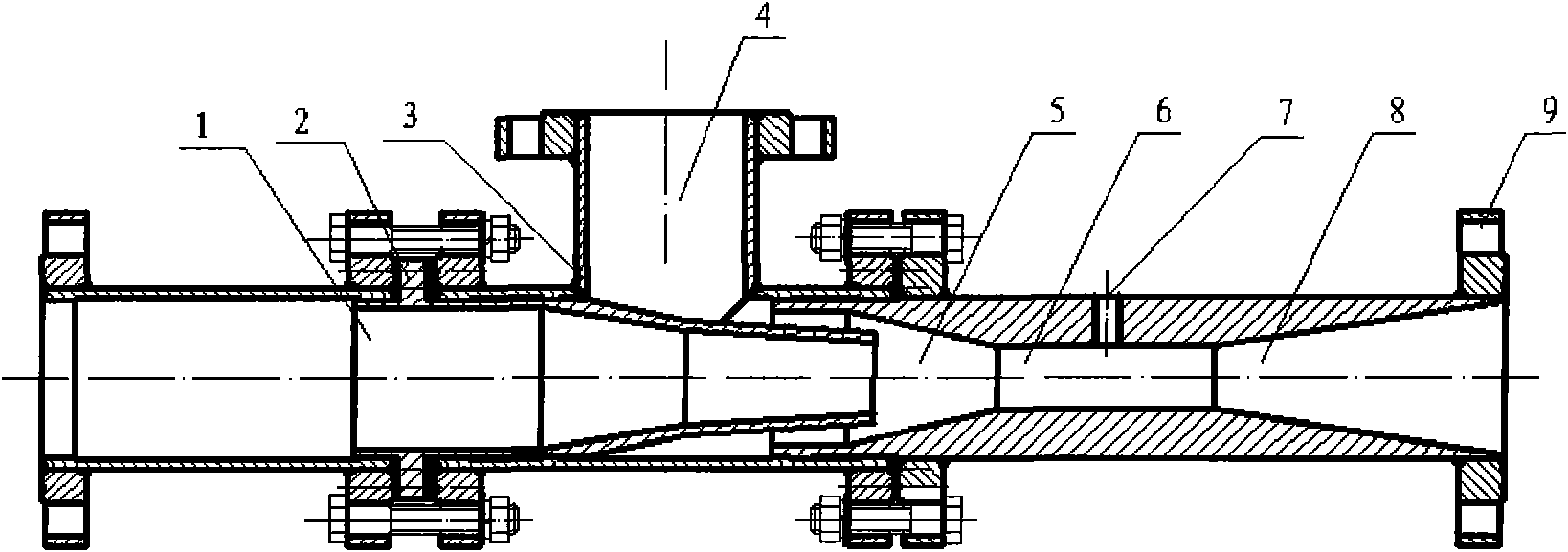

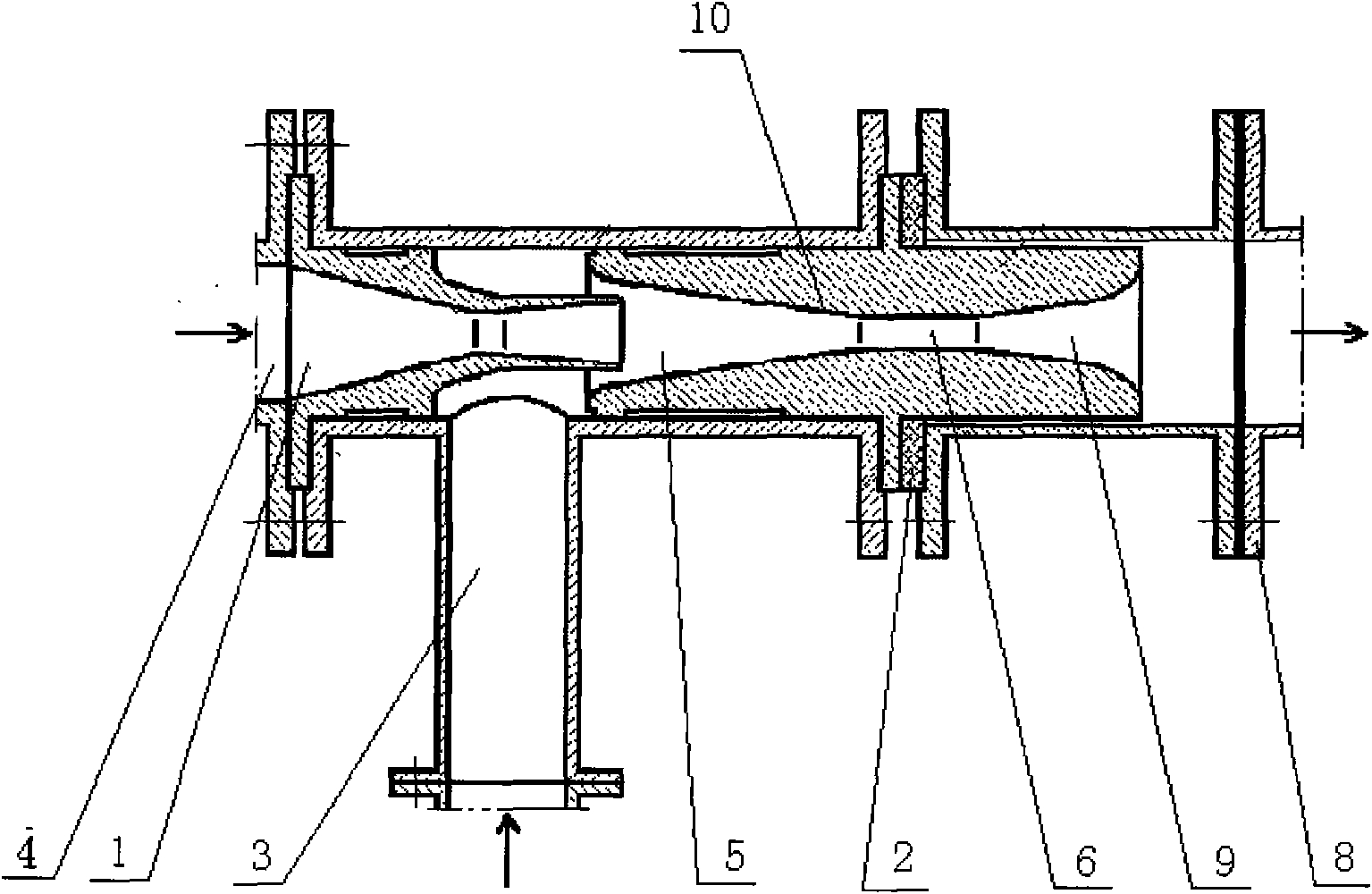

[0017] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

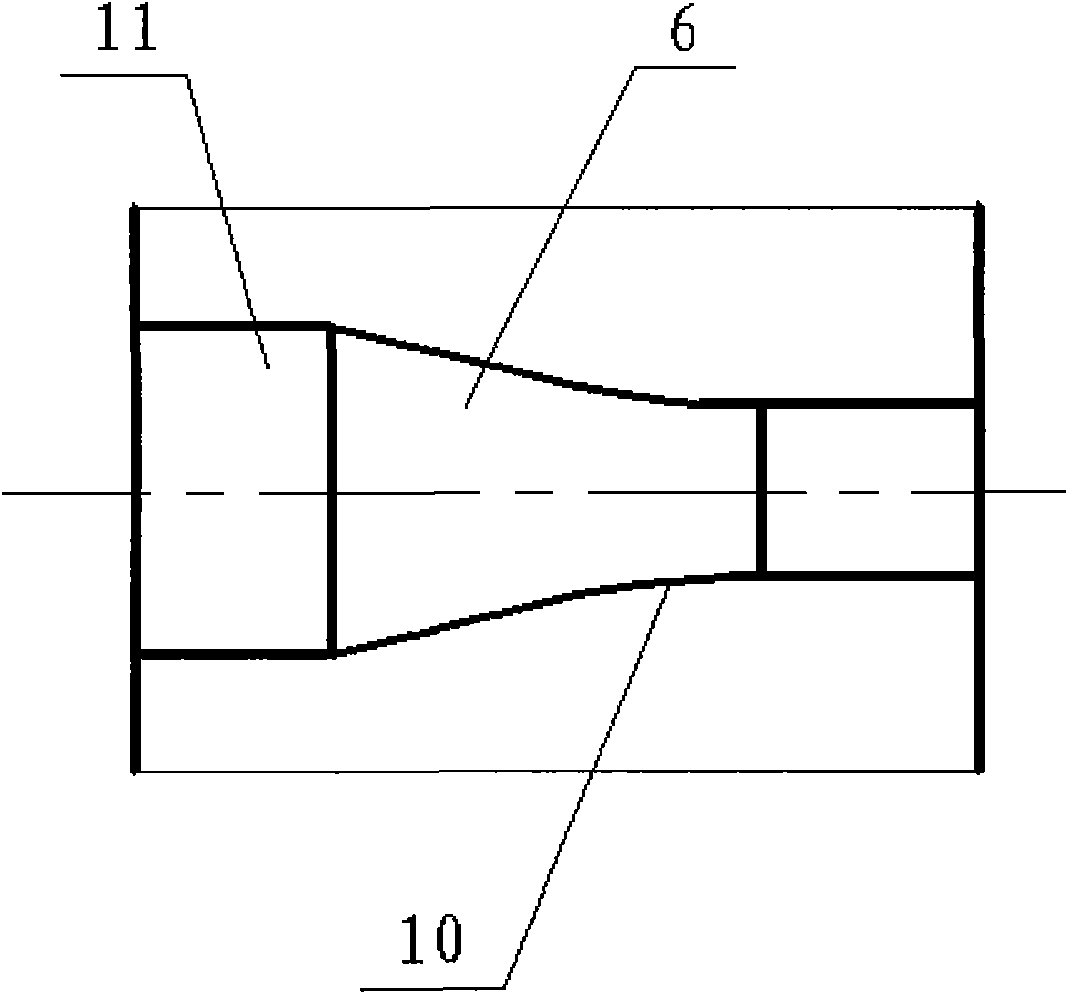

[0018] Such as figure 1 combine figure 2 As shown, this embodiment is mainly composed of a nozzle 1, an adjusting gasket 2, a three-way housing 2, a pressurized mixing tube 5, a mixing chamber 6, and a diffuser chamber 9. The three-way housing 3 is provided with a steam inlet (water) mouth, water inlet (steam) mouth 4, water outlet, spray pipe 1 links to each other with the inlet steam (water) on the tee shell 3 by flange connection form. In order to adjust the water intake and steam intake, an adjusting gasket 2 is provided at the connection between the nozzle 1 and the tee housing 3 to change the distance between the nozzles and adjust the water (steam) intake. The cavity of the pressurized mixing chamber 5 is a tapered structure, its large diameter is connected to the nozzle 1, and the small diameter end communicates with the mixing chamber 6, and the matching part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com