Automatic dust removal heat dissipation monitoring camera

A monitoring camera and self-dust removal technology, applied in the field of cameras, can solve problems such as easy damage, impact on shooting quality, and unfavorable heat dissipation of equipment, and achieve the effects of improving work effect, reducing work pressure and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

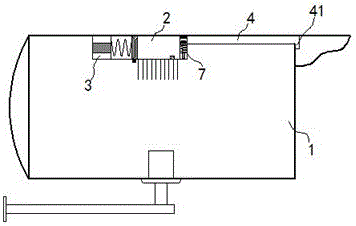

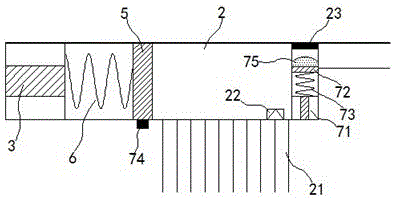

[0018] exist figure 1 , figure 2 In the illustrated embodiment, the self-dust-removing and heat-dissipating monitoring camera includes a housing 1 and a lens,

[0019] A heat-absorbing chamber 2 is fixed inside the housing 1, an electromagnet element 3 is installed at the bottom of the heat-absorbing chamber 2, and an air injection port is opened on the top; an air guide pipe 4 is connected to the air ejection port, and the air outlet end of the air guide pipe 4 41 extends out of the housing 1 and is close to the lens; the air outlet direction of the air outlet 41 of the air guide tube 4 is parallel to the mirror surface; heat absorbing fins 21 are installed on the outer wall of the heat absorbing chamber 2;

[0020] A piston plate 5 made of ferromagnetic material is slidably installed in the heat-absorbing cavity 2, and the piston plate 5 is connected with the electromagnet element 3 through a compression spring 6; Air intake pipe 22, the one-way air intake pipe 22 is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com