A gas reaction chamber for preparing ybco strips by mocvd

A gas reaction chamber and reaction technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low utilization rate of metal-organic sources, uneven temperature field distribution, uneven film thickness, etc., to achieve Ensure out-of-plane uniformity and consistency, improve utilization rate, and achieve the effect of small diffusion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

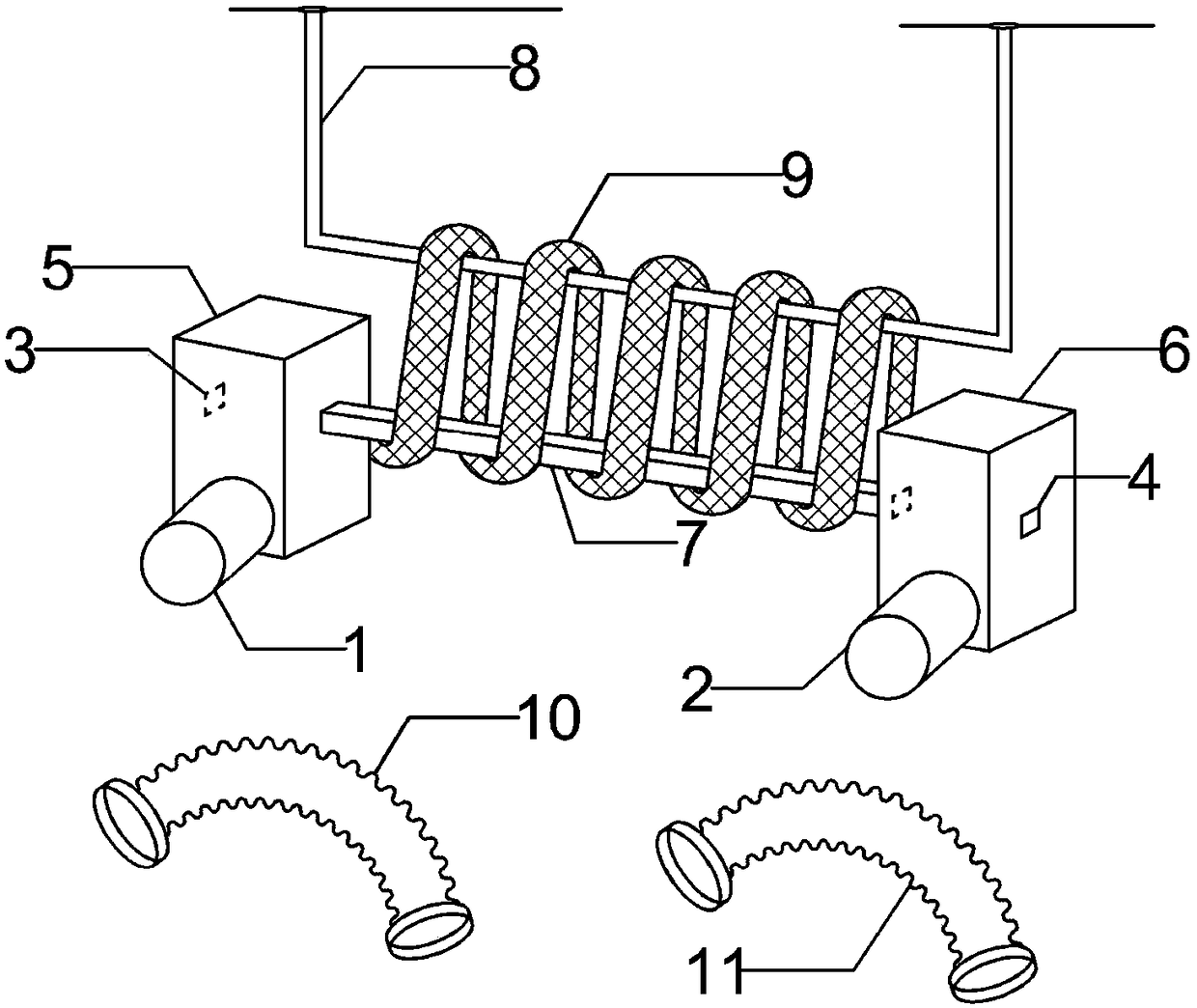

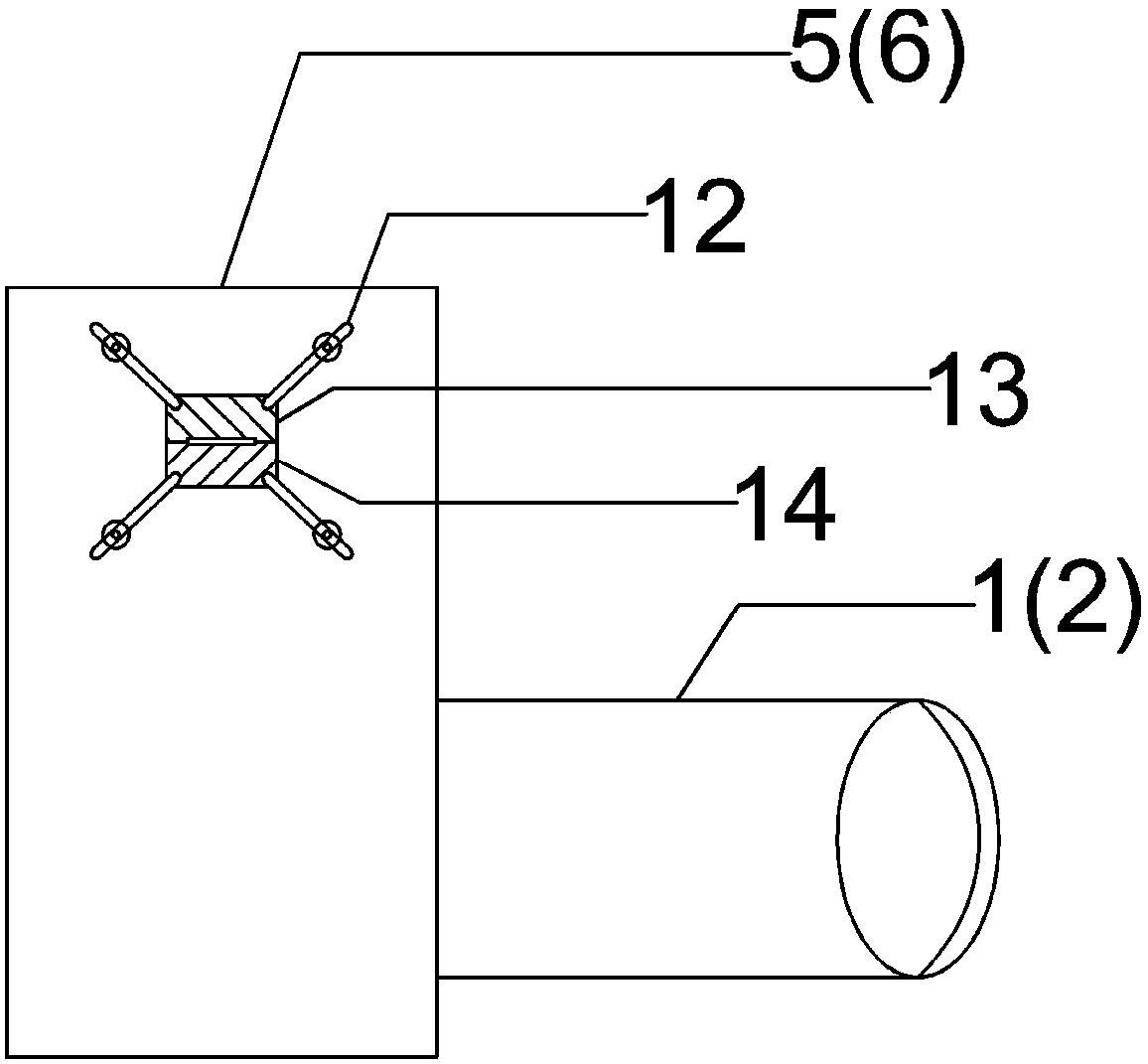

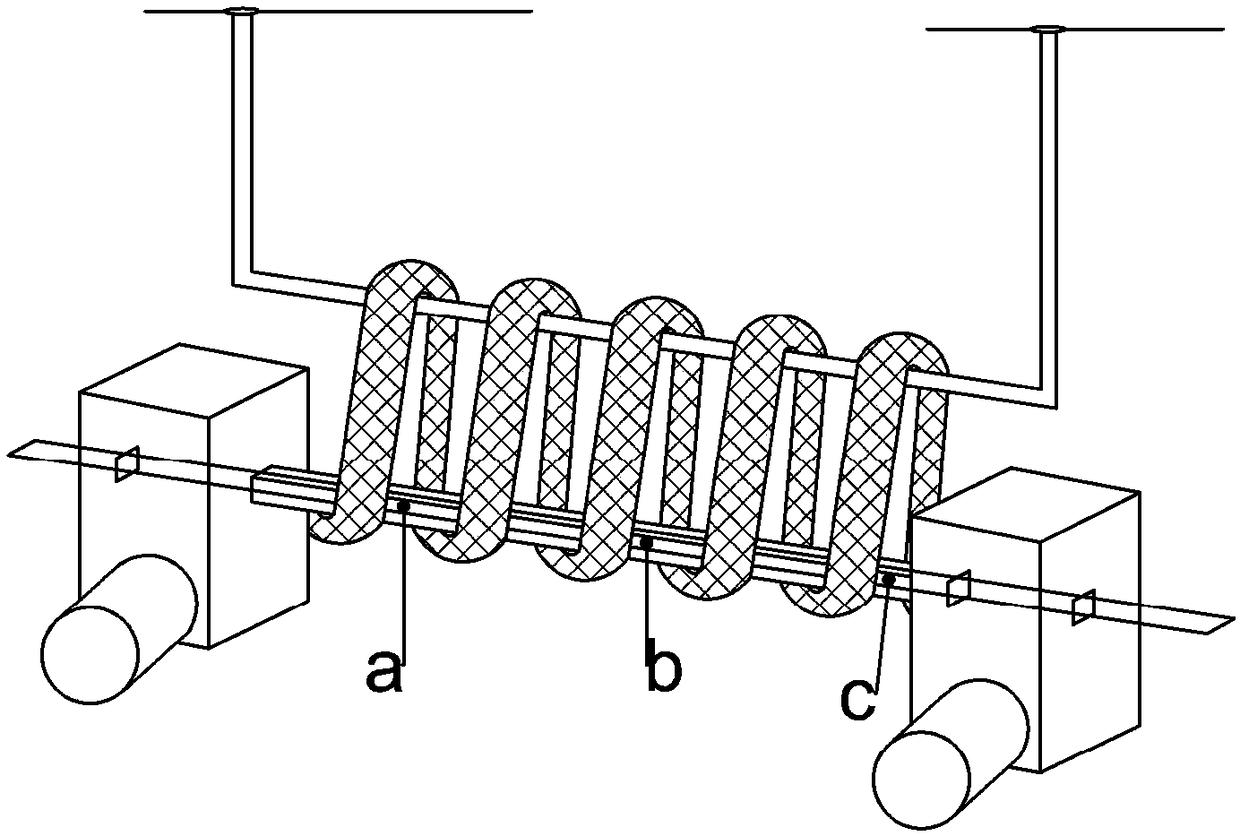

[0022] figure 1 The slender copper tube in the middle of the reaction chamber is the reaction tube, and the metal substrate baseband deposits thin films in it. The reaction copper tube is wound with a copper conduction belt and connected to the condensation tube outside the reaction chamber. The metal substrate baseband itself is heated by current, and the resulting heat radiation makes the temperature in the reaction copper tube very high. Because copper has good Thermal conductivity, in order to prevent the metal-organic source from reacting before reaching the surface of the substrate base tape, the copper conduction tape can conduct excessive heat to the condenser pipe, effectively inhibiting this from happening. Two copper hoses (10, 11) are respectively connected to the evaporation tube in the MOCVD equipment and the exhaust pipe connected to the vacuum pump. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com