Flow channel adjustable reaction cavity device for thin film prepared by MOCVD

A technology of reaction chamber and flow channel, which is applied in the field of gas reaction chamber devices, can solve the problems of affecting deposition rate, blockage of shower head, and generation of reaction deposition film, etc., and achieves the effects of small diffusion space, improved utilization rate and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

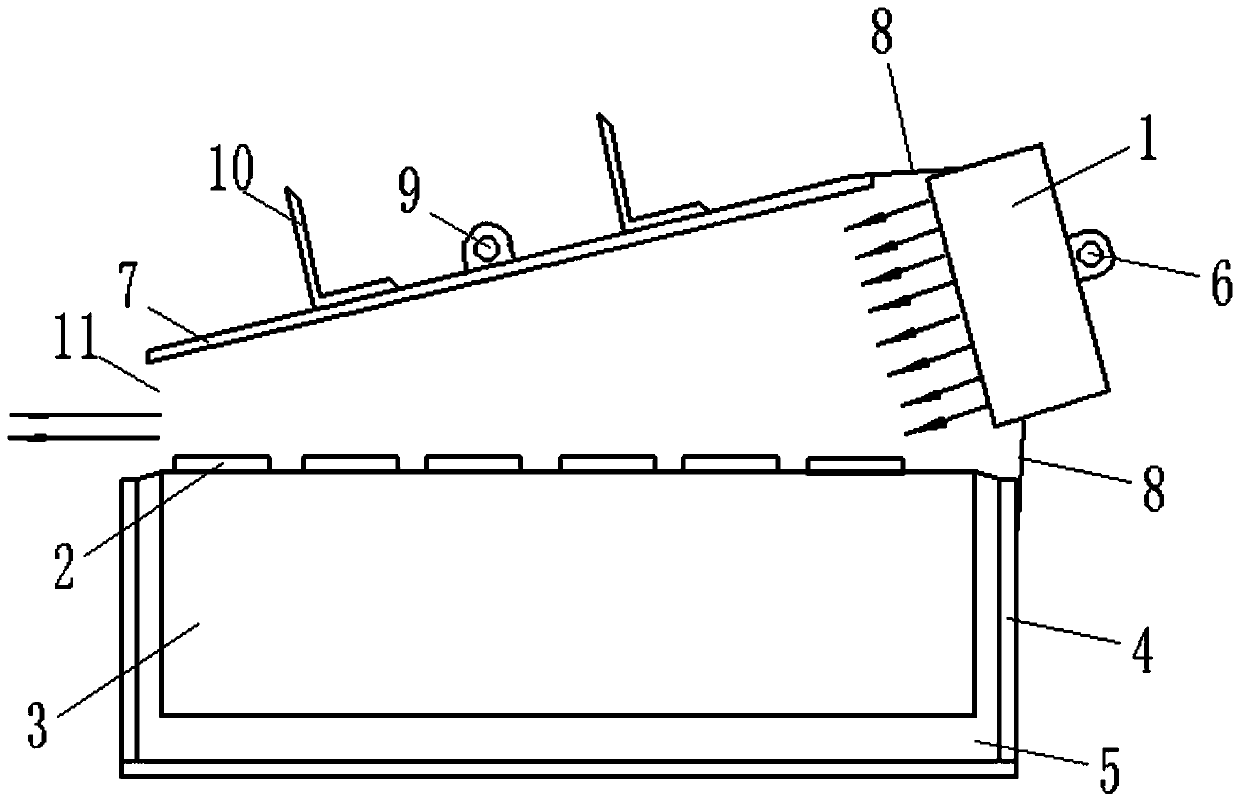

[0020] as attached figure 1 As shown, a flow channel adjustable reaction chamber device for MOCVD film preparation includes a heater 3, an adjustable shower head 1, an angle adjustable cold wall 7 and an elastic sealing sheet 8; above the heater 3 is set There is an angle-adjustable cold wall 7; the adjustable shower head 1 is arranged on one side of the angle-adjustable cold wall 7; an elastic seal is arranged between the adjustable shower head 1 and the angle-adjustable cold wall 7 Sheet 8; an elastic sealing sheet 8 is provided between the adjustable shower head 1 and the heater 3; the other side of the adjustable angle cold wall 7 is provided with a flow outlet 11 between the heater 3; The heater 3 is provided with a heater shell 5; the adjustable shower head 1, the heater 3, the heater shell 5, the angle-adjustable cold wall and the elastic sealing sheet 8 form a single-ended open space ; The heat insulating layer 4 is arranged between the heater 3 and the heater shell 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com