Battery filling machine

A liquid injection machine and battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as low production efficiency, low product quality, and inability to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

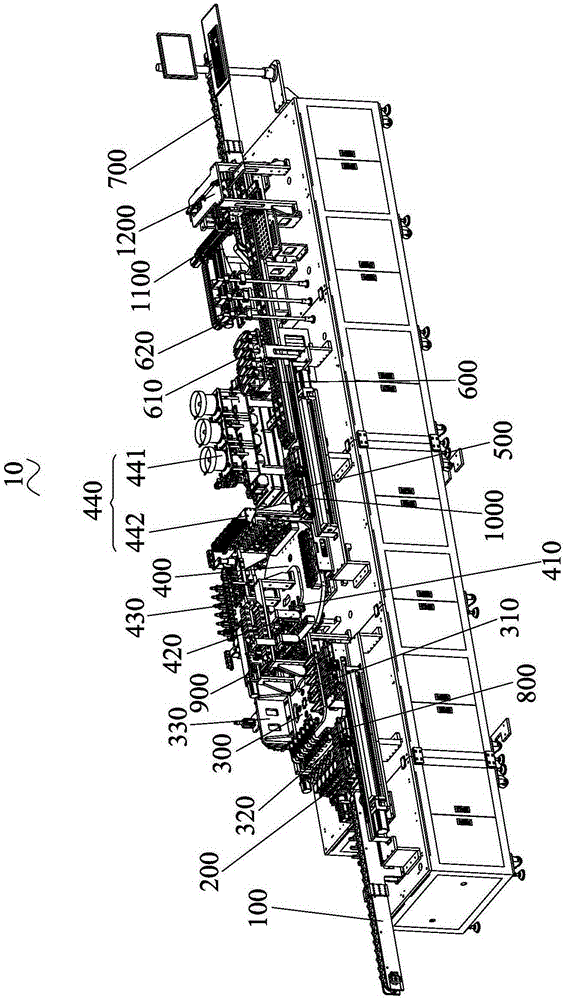

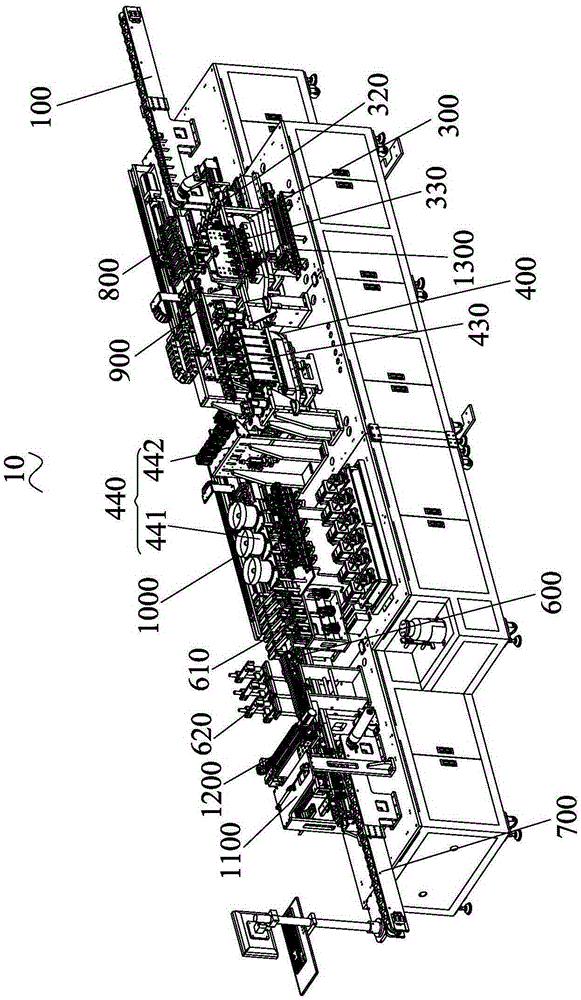

[0044] Please also refer to figure 1 and figure 2 , which are structural diagrams of the battery liquid injection machine 10 under two different viewing angles.

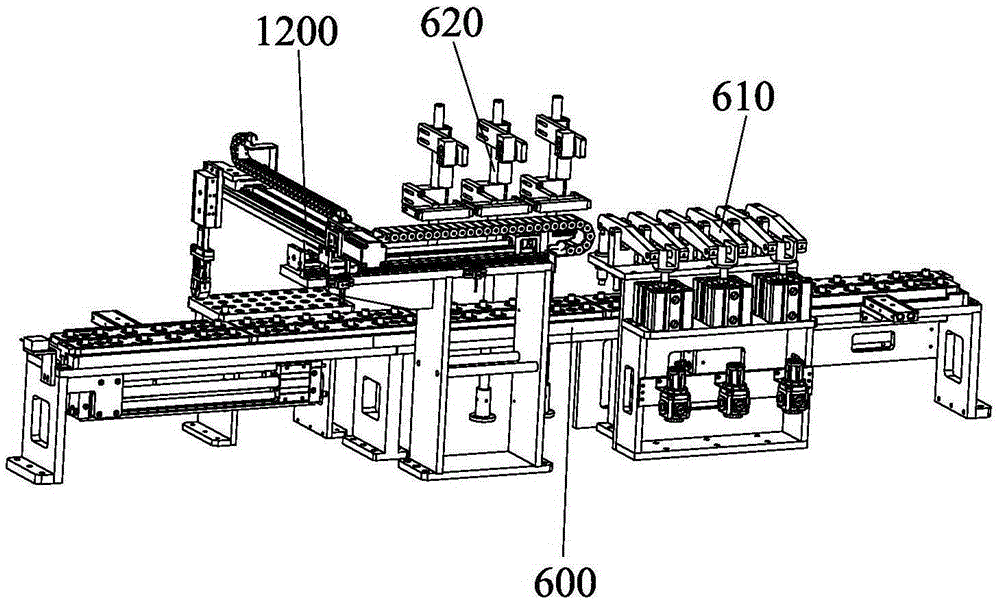

[0045] The battery liquid injector 10 is used to inject liquid into the battery, and perform rivet pressing on the battery hole after the liquid injection. The battery liquid injection machine 10 includes: a feeding line 100, a front weighing device 200, a first turntable 300, a second turntable 400, a rear weighing device 500, a main flow line 600, and a feeding line 700, which are connected to the feeding line 100, The feeding manipulator 800 between the front weighing station 200 and the first turntable 300, the transfer manipulator 900 connected between the first turntable 300 and the second turntable 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com