Stacker

A palletizer and frame technology, applied in the field of object stacking, can solve the problems of unfavorable mechanized production, low efficiency, high labor intensity, etc., and achieve the effects of improving labor efficiency, best technical effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing

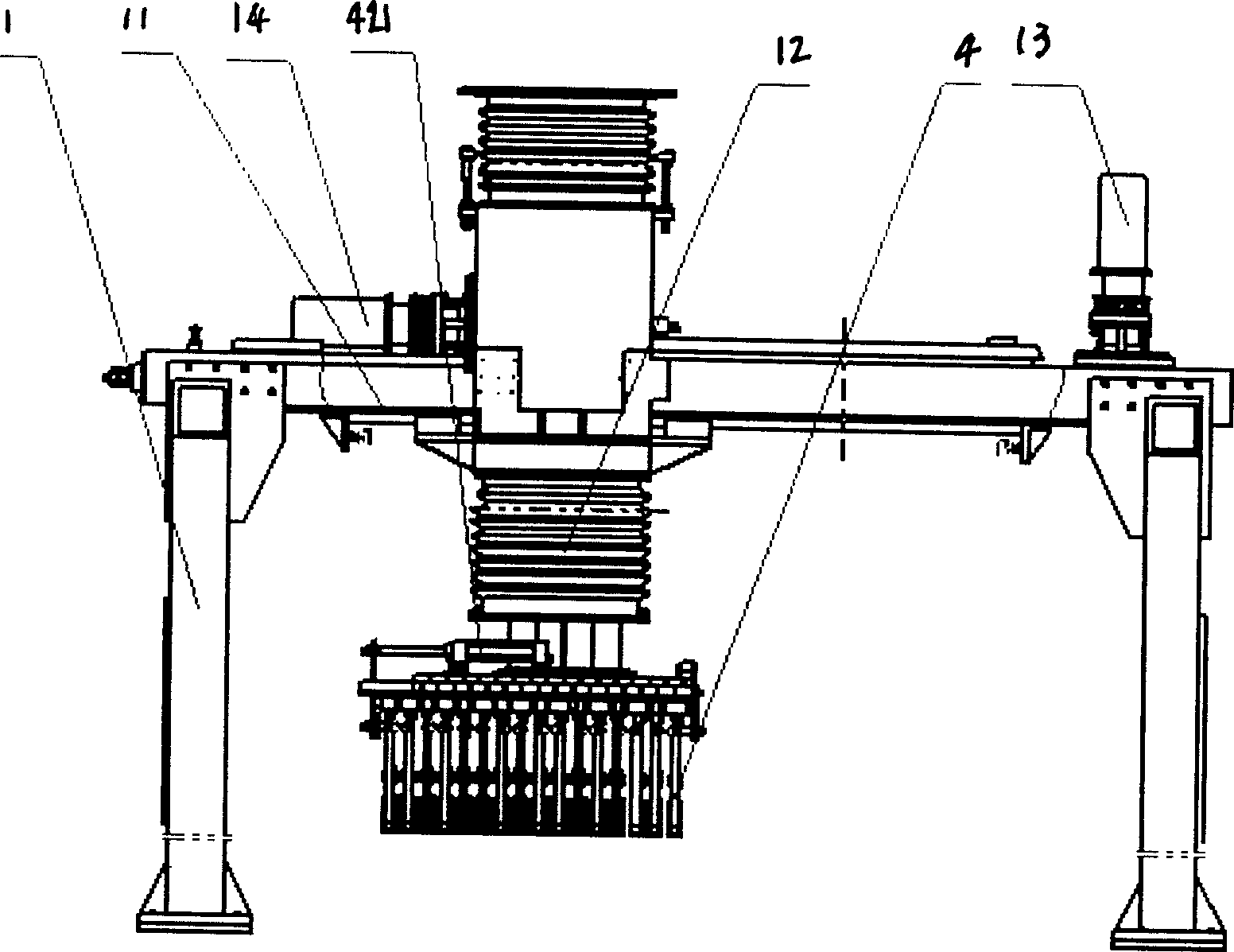

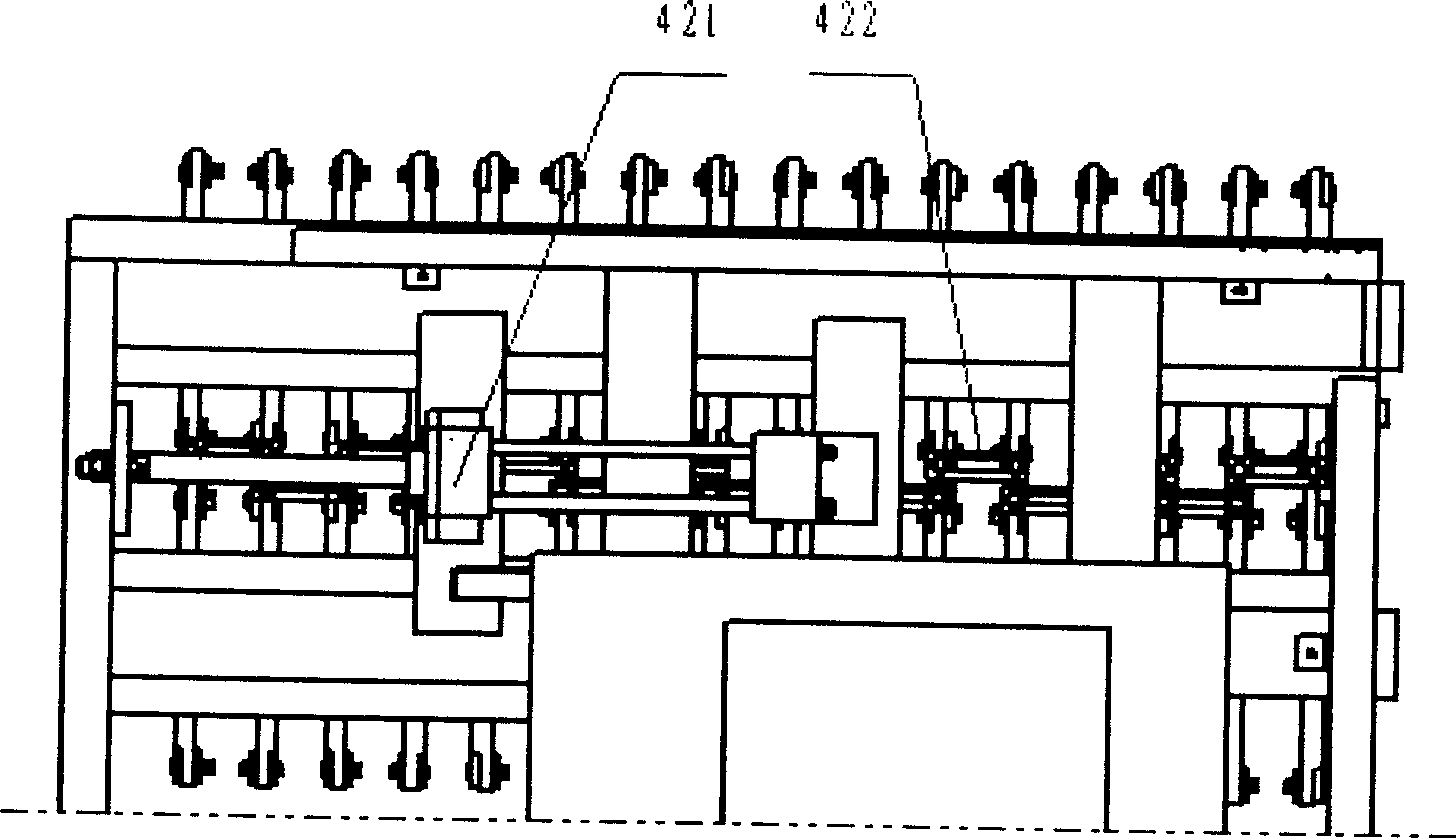

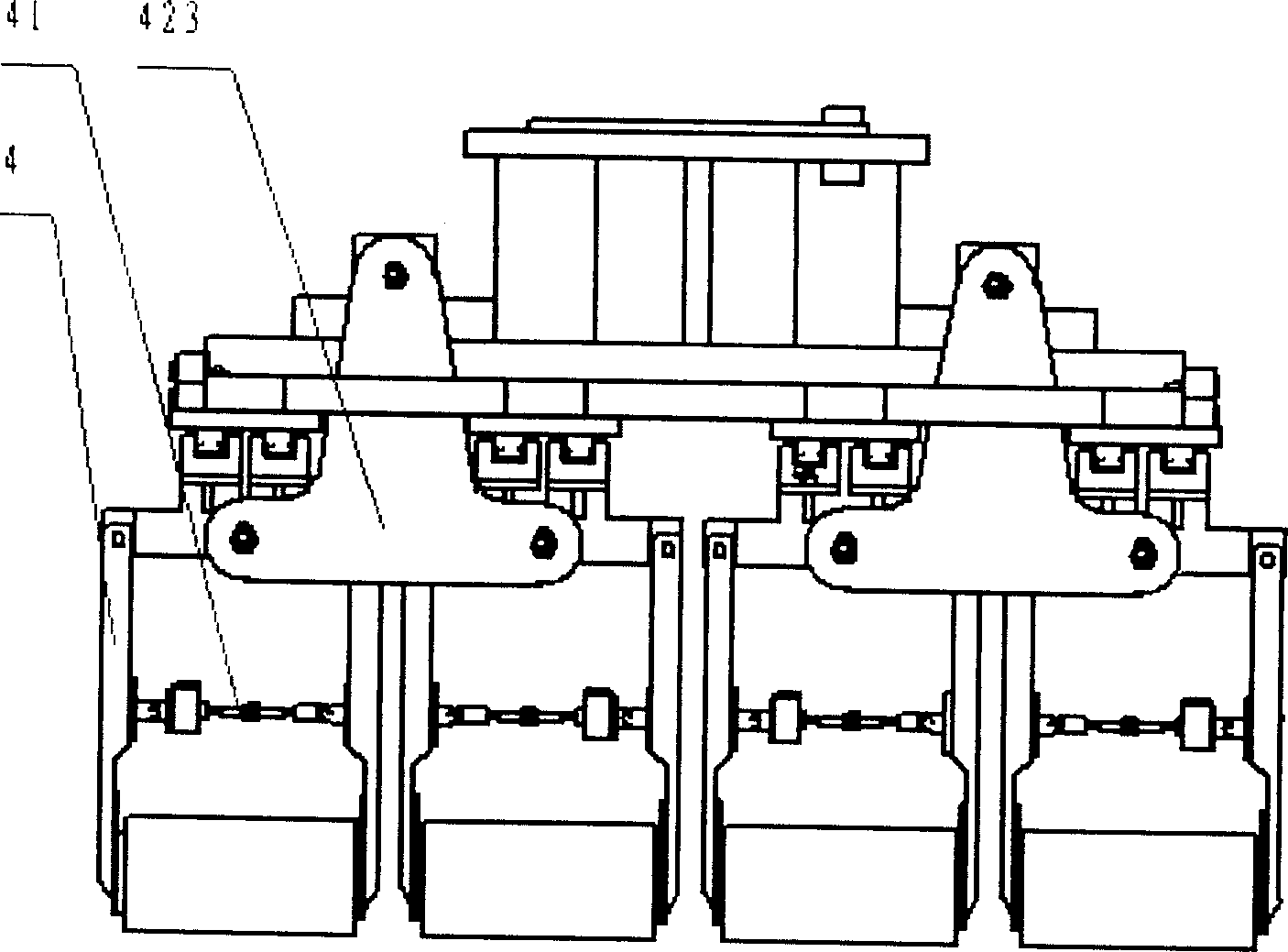

[0024] Such as figure 1 , figure 2 , image 3 Shown, a kind of palletizing machine comprises frame 1, control device, horizontal motor 13, vertical motor 14, is fixed with linear guide rail 11 on frame, is fixed with lifting base 12 on linear guide rail 11, and lifting base has two movements The direction is driven by two motors. A horizontal motor 13 is fixed on the frame 1 to control the lifting base 12 to move along the linear guide rail. A vertical motor 14 is fixed above the lifting base 12 to control the lifting base 12 to move up and down. The lifting base 12 There are 128 manipulators 4 installed at the bottom, each of which forms a pair, and there is a clamping mechanism 41 between each pair. The distribution rule is that there are four rows in the horizontal direction and 16 rows in the vertical direction. Every two rows of manipulators 4 are connected with a shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com